4

The following section describes our recommendations to help you in deciding which types of accessories to purchase for

your new Wattage Cub 400EP ARF. We have tested all of these items with the airplane and found that these products will

offer the best in performance, reliability and economy.

OUR RECOMMENDATIONS

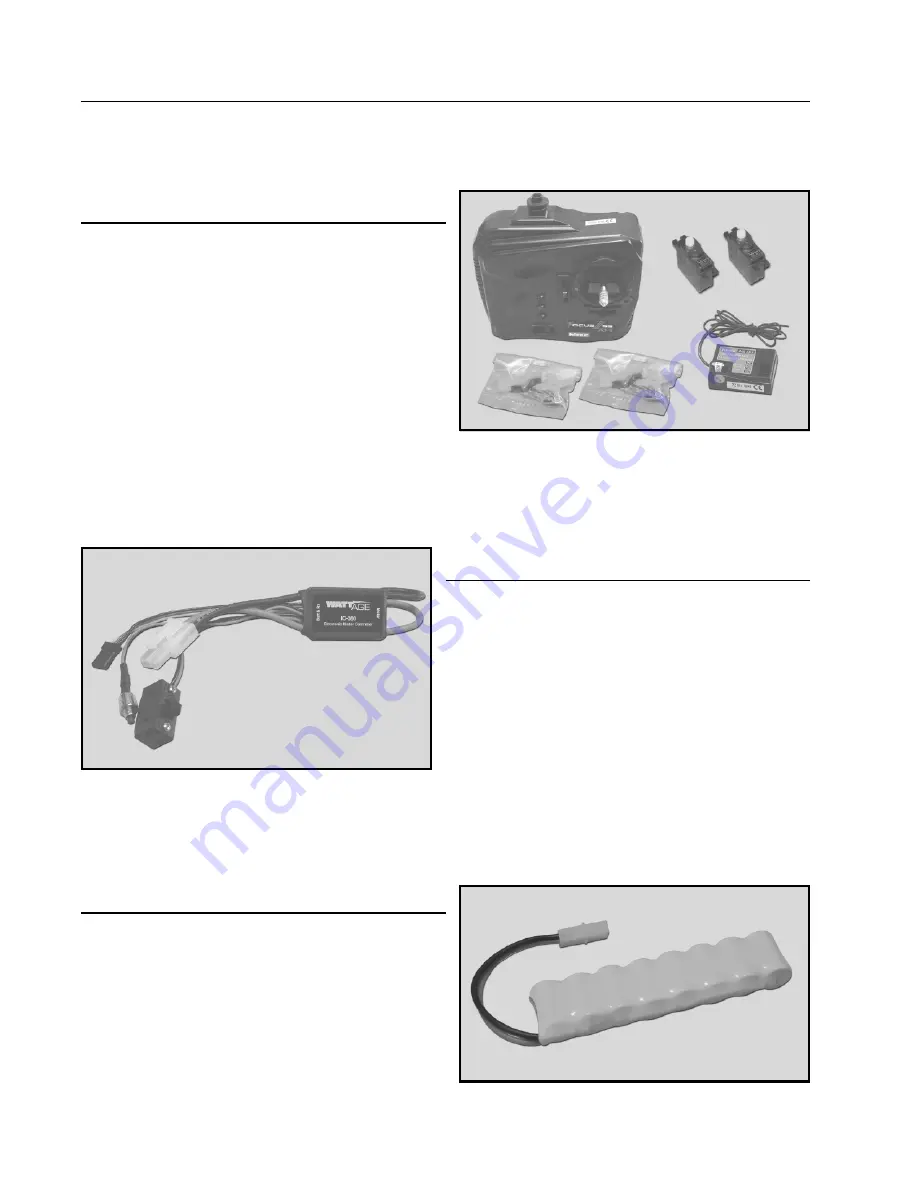

RADIO SYSTEM

The Cub 400EP will require a minimum 3 channel radio

control system with two micro servos. The radio system we

recommend using is the Hitec Focus 3 AM radio with 2 HS-81

Micro servos. This radio system includes two micro servos,

a three channel mini receiver, servo mounting hardware and

a setup guide.

If you want to purchase a radio system that will be more

upgradeable in the future, a four or more channel radio with

two micro servos and a mini or micro receiver will work

well. If you decide to go this way, our recommendation

would be to use the Hitec Flash 4X Glider FM Computer

radio with 2 HS-81 Micro servos. This is a very good radio system that offers the capability to grow as your experience

grows.

If you already have a standard radio system, you will need to purchase an after-market mini or micro receiver and two

micro servos. If you need to purchase these items we recommend the Hitec Micro 555 receiver (part # 759118) and two

Cirrus CS-21 Micro servos (part # 444227).

ELECTRONIC SPEED CONTROL

To operate the motor, we suggest using a proportional elec-

tronic speed control (ESC) that features battery eliminator

circuitry (BEC) and auto-cutoff. BEC allows you to elimi-

nate the receiver battery and uses the flight battery to control

both the motor and the radio system. Eliminating the receiver

battery provides a great weight savings which effectively in-

creases performance. The auto-cutoff feature turns off the

motor when the voltage in the battery drops too low to oper-

ate the radio system safely. This guarantees safe operation

throughout the entire flight. To obtain these features, we sug-

gest using the Wattage IC-380 ESC. You can also upgrade to the Wattage IC-14 ESC (part # 128484). This ESC is

smaller and lighter, and includes special tabs that hook directly to most Speed 400 motors. This means there isn't any

soldering required and you won't experience current loss because of poor connectors. If you decide not to use a propor-

tional electronic speed control, an electronic switch like the Hitec Motor Controller SP-1003 (part # 759850) is an

economical way to turn the motor on and off. This switch does not offer any proportional speed, only off or full power.

The flight battery you choose should be an 8 cell (9.6Volt)

Nickel Cadmium battery pack or an 8 cell Nickel Metal Hy-

dride battery pack. We recommend either the Wattage 8 cell

600Mah NiCd Battery or the Wattage 8 cell 800Mah

NiMhbattery (part # 128523). Both battery packs come

prewired with Tamiya connectors so they will be compatible

with the Wattage IC-380 ESC. The Nickel Metal Hydride

battery will give you about 25% more run-time; however, it

will not produce quite the amount of power as the Nickel

Cadmium battery.

FLIGHT BATTERY

P/N 128522

P/N 128471

Focus 3 AM