14

❑

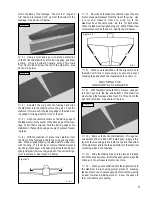

10) Carefully slide one 45mm diameter wheel onto

the axle, followed by a second 3mm nylon wheel retainer.

Align the predrilled hole in the outside of the wheel pant

and push it over the end of the axle.

See figure # 5 below.

Figure # 5

❑

11) Secure the wheel pant to the landing gear wire

using one prebent aluminum wheel pant mount and two

2mm x 6mm wood screws. Thread the screws into the

predrilled holes and tighten both of them firmly to hold

the wheel pant in place.

See photo # 17 below.

Photo # 17

☛

A small piece of plywood has been preglued to the

inside surface of the wheel pant for the wood screws to

thread into.

❑

12) Repeat steps # 9 thru # 11 to install the second

wheel and wheel pant assembly.

TOOLS AND SUPPLIES REQUIRED

SERVO INSTALLATION

❑

# 0 Phillips Head Screwdriver

❑

Excel Modeling Knife

❑

Electric or Hand Drill

❑

1/16" Drill Bit

INSTALLING THE SERVOS

❑

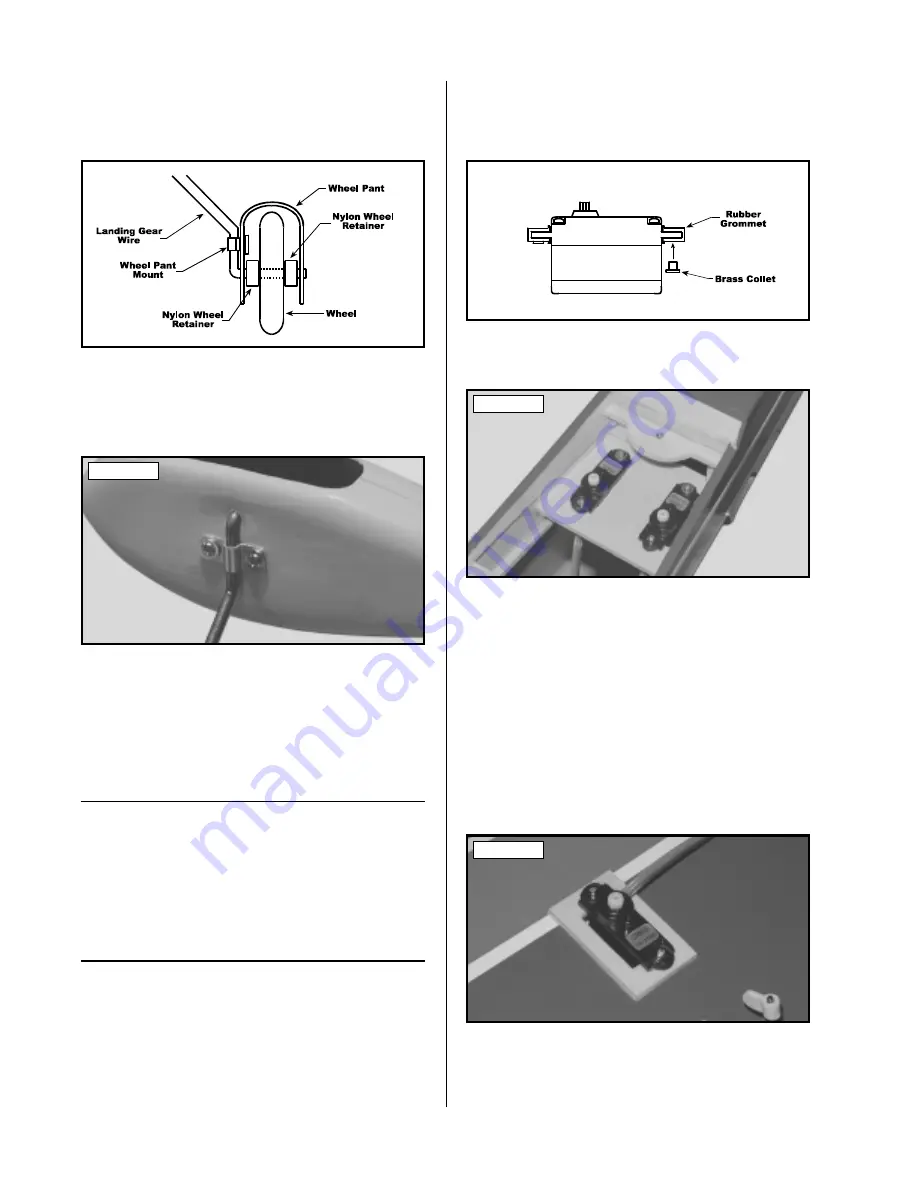

1) Using a # 0 phillips screwdriver, remove the two

wood screws that hold the canopy deck in place. Remove

the canopy deck from the fuselage and set it aside.

❑

2) Locate the three servos you intend to use for the

elevator, rudder and aileron controls. Carefully install the

rubber grommets and brass collets onto each of the servo

mounting lugs. For proper vibration reduction, the brass

collets should be inserted into the rubber grommets with

the flanges facing the bottom of the servo mounting lugs.

See figure # 6 below.

❑

3) Position two servos into the fuselage servo tray,

making sure that both servo output shafts face the front of

the fuselage.

See photo # 18 below.

Figure # 6

Photo # 18

❑

4) Using a drill with a 1/16" drill bit, drill pilot

holes through the servo tray, one for each of the servo

mounting screws (included with your radio system). Us-

ing a # 0 phillips screwdriver, install and tighten the

mounting screws to hold the servos in place.

☛

Drilling pilot holes through the servo tray will make

it easier to install the mounting screws.

❑

5) Place the remaining servo into the plywood ai-

leron servo tray, noting the position of the servo output

shaft. It should face the leading edge of the wing.

See

photo # 19 below.

Photo # 19

☛

When installing the aileron servo, make sure you

run the servo wire out the precut notch in the side of the

servo tray.