18

❑

14) Remove the masking tape from the rudder and

double check that both the rudder and the rudder servo

are still centered.

☛

To adjust the center-trim of the rudder, use a pair of

pliers to carefully open or close the "V" in the pushrod

wire. Doing this will effectively lengthen or shorten the

pushrod wire.

ADJUSTING THE RUDDER PUSHROD

❑

15) With your radio system plugged in and turned

on, check the direction the rudder control surface moves

and the amount of control deflection. To do this push

right on the rudder control stick. The rudder should move

right. If it does not, flip the servo reversing switch on

your transmitter to change the direction.

❑

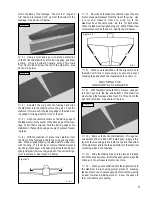

16) Push right completely on the rudder control stick.

While holding the control stick completely right, use a ruler

and measure the amount the trailing edge of the rudder

moves right. This measurement should be 1/2" measured

at the widest point of the rudder.

See figure # 8 below.

Figure # 8

❑

17) If the control surface deflection is more or less

than 1/2" it must be changed. If your radio is equipped

with End Point Adjustments (EPA), make those adjust-

ments using the transmitter. (Refer to your radio guide

for further details.) If your radio does not have this fea-

ture, you can still make the adjustments to the pushrod

manually.

❑

18) If the rudder is moving

more

than 1/2", move

the Z-bend in one hole toward the center of the servo horn

to decrease the control deflection. If the rudder is mov-

ing

less

than 1/2", move the Z-bend out one hole from the

center of the servo horn to increase the control deflection.

When adjusted properly, the rudder should move 1/2" both

right and left.

☛

Double check that both the elevator and the rudder

pushrods move without binding. If there is any binding

present, use a pair of pliers to make very small bends in

the pushrod wires until they move smoothly.

PARTS REQUIRED

TOOLS AND SUPPLIES REQUIRED

AILERON LINKAGE

❑

# 0 Phillips Head Screwdriver

❑

Needle Nose Pliers

❑

Wire Cutters

❑

Magnum Z-Bend Pliers

❑

Straight Edge Ruler

❑

Pen or Pencil

❑

Masking Tape

❑

{2} 1mm x 110mm Pushrod Wires

6

ADJUSTING THE CONTROL HORNS

❑

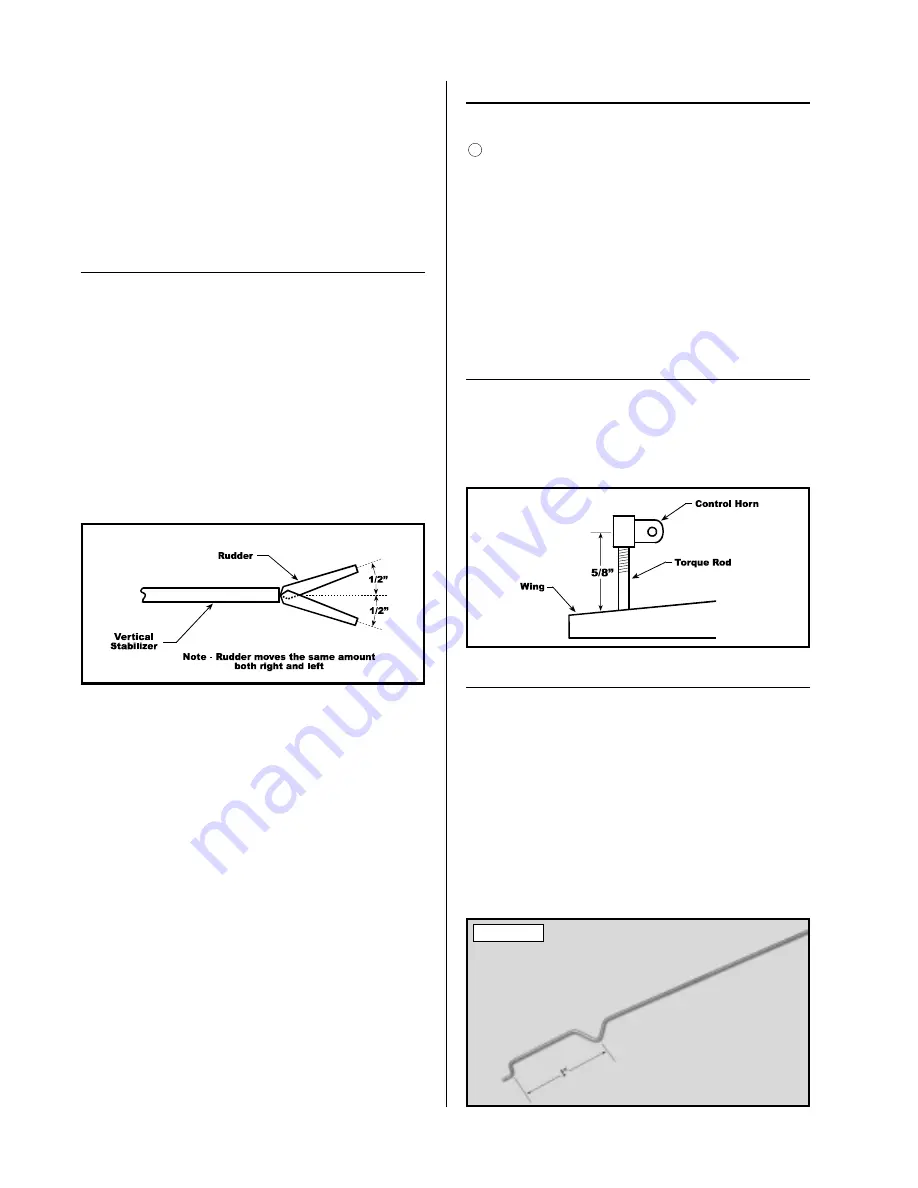

1) Two nylon adjustable control horns have been

partially threaded onto the two aileron torque rods. Thread

the control horns into their final positions. The centerline

of each control horn should be 5/8" up from the top of the

wing.

See figure # 9 below.

Figure # 9

INSTALLING THE AILERON LINKAGE

❑

2) Using Magnum Z-Bend Pliers, make a Z-bend

in only one end of each of the two 1mm x 110mm push-

rod wires. Use wire cutters to remove any excess wire,

leaving about 3/16" of wire beyond the Z-bends.

❑

3) Using a ruler and a pen, measure forward 1" from

the middle of the Z-bend and draw a mark. Do this on

both of the pushrod wires.

❑

4) Using a pair of needle nose pliers, carefully bend

a "V" shape into each of the two pushrod wires at the

marks you drew.

See photo # 29 below.

Photo # 29