8

❑

9) With the motor turned off, test the operation of

the three servos. Each servo should move when you move

the control sticks.

❑

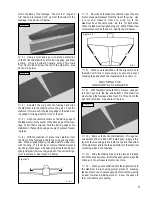

10) Carefully spray a couple of light sprays of Per-

formance Plus Motor Spray inside the motor openings and

apply a small drop of Trinity Break-In Drops onto each of

the two motor bushings and onto the gear box bearings.

See photo # 3 below.

Photo # 3

❑

11) Using a couple of paper towels, wipe off the

excess motor spray.

❑

12) Slowly turn on the motor using the transmitter

throttle control stick. Position the stick to about 1/3 throttle

and let the motor run. While the motor is running, apply

a light spray of motor spray inside the motor openings

once every minute, followed by a small drop of Break-In

Drops on each of the motor bushings and gear box bear-

ings. Continue to do this until the battery is fully

discharged (i.e., the motor stops).

❑

13) After the battery has discharged and the motor

has stopped, spray motor spray through the motor open-

ings until the fluid runs clear. Apply a couple of drops of

Break-In Drops to the motor bushings and gear box bear-

ings and wipe away all of the excess using paper towels.

❑

14) Reinstall the motor assembly and the cowling.

Reverse the removal steps for installation.

PARTS REQUIRED

TOOLS AND SUPPLIES REQUIRED

WING MOUNTING

❑

# 1 Phillips Head Screwdriver

❑

Excel Modeling Knife

❑

Straight Edge Ruler

1

2

23

MOUNTING THE WING

❑

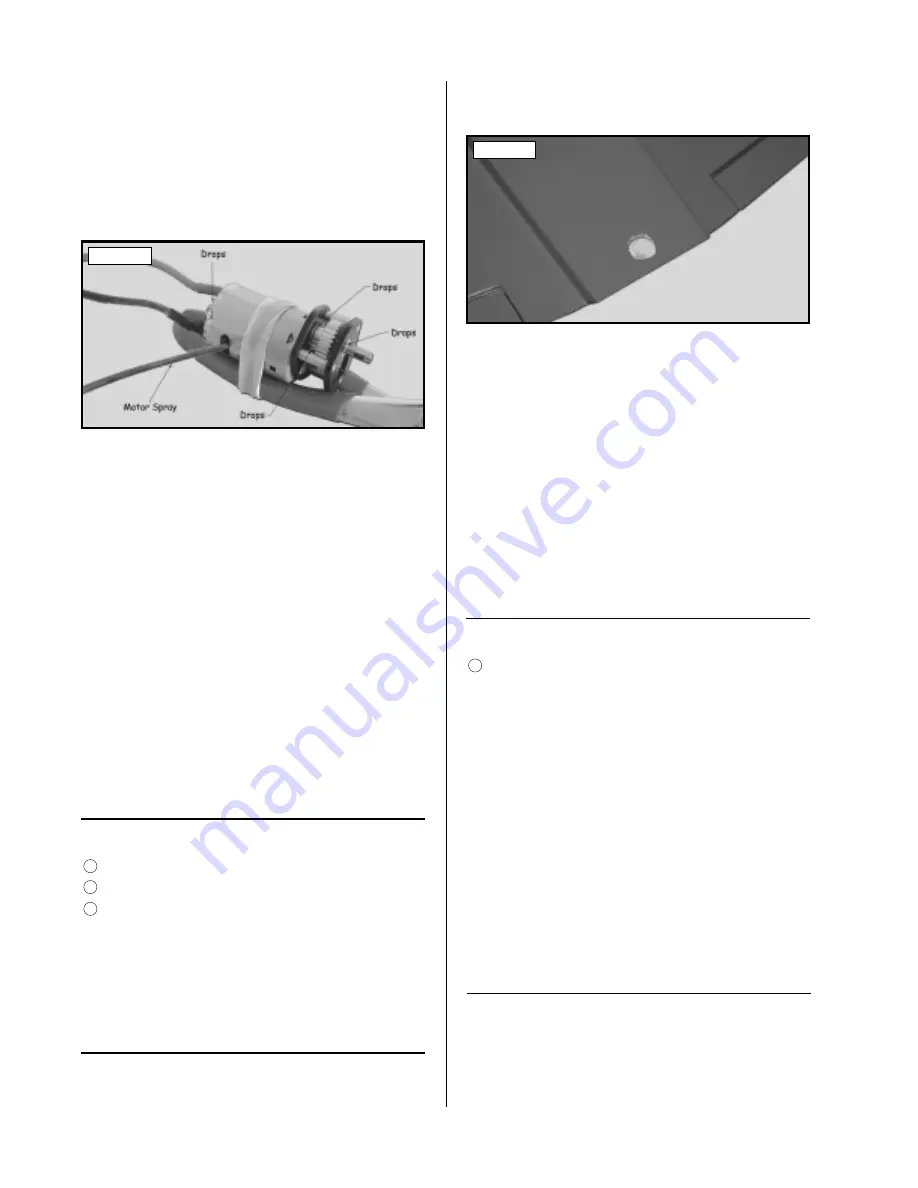

1) Using a modeling knife, cut away the covering

material from over the predrilled wing hold down hole in

the bottom of the belly pan. The hole is located 1/2" in

front of the trailing edge and is 7/16" in diameter.

See

photo # 4 below.

Photo # 4

❑

2) Using a modeling knife, cut away the covering

material from over the 1/8" diameter hole located on the

top of the wing, directly above the hole in the belly pan.

❑

3) Place the wing into the wing saddle, making sure

that the dowel in the leading edge of the wing engages the

predrilled hole in the forward bulkhead.

❑

4) Line up the trailing edge of the wing with the

fuselage and install the wing using the 3mm x 15mm

machine screw. Tighten the machine screw firmly using

a # 1 phillips screwdriver.

☛

The plywood wing hold down block has threads

tapped into it for the bolt to thread into.

PARTS REQUIRED

TOOLS AND SUPPLIES REQUIRED

HORIZONTAL STABILIZER

❑

Kwik Bond 5 Minute Epoxy

❑

Excel Modeling Knife

❑

Straight Edge Ruler

❑

Builder's Triangle

❑

220 Grit Sandpaper w/Sanding Block

❑

Pen or Pencil

❑

Masking Tape

❑

Rubbing Alcohol

❑

Paper Towels

❑

NHP Epoxy Mixing Sticks

❑

NHP Epoxy Mixing Cups

❑

{1} Horizontal Stabilizer w/Elevator & Hinges

3

❑

1) Remove the elevator and hinges from the hori-

zontal stabilizer and set them aside for now. Remove the

wing from the fuselage and set it aside, also.

❑

2) Using a modeling knife, carefully remove the

covering from over the horizontal stabilizer mounting

ALIGNING THE

HORIZONTAL STABILIZER

❑

{1} Fuselage w/Motor, Cowling & Canopy Deck

❑

{1} Prejoined Wing w/Ailerons & Hinges

❑

{1} 3mm x 15mm Machine Screw