11

❑

5)

Install the servo tray into the fuselage. To align

the servo tray properly, the back edges of the servo tray

mounting sides should be pushed up against the front of

the aluminum wing mounting tube, and the tops of the

servo tray mounting sides should be pushed up against

the bottom of the wing saddle. See photo # 17 below.

❑

6)

When satisfied with the alignment, press the

servo tray sides firmly into place to secure the tray into

the fuselage.

INSTALLING THE SERVOS

❑

7)

Install the rubber grommets and brass collets onto

each of the servo mounting lugs.

❑

8)

Test fit your two micro servos into the servo tray.

If necessary, use a modeling knife to enlarge the hole in

the servo tray to accommodate the two servos. The ser-

vos should fit tightly in the servo tray.

☛

Both of the servos' output shafts should face toward

the front of the fuselage.

❑

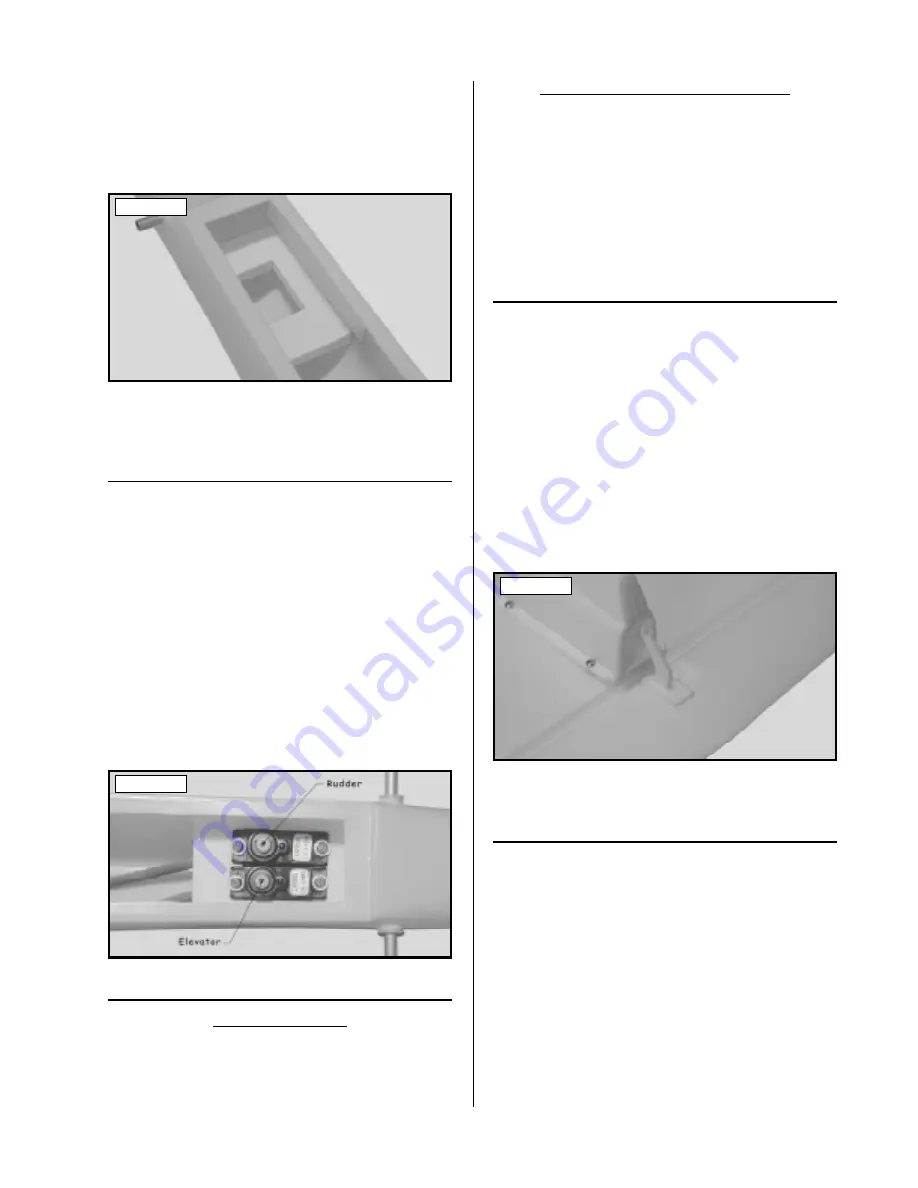

9)

Mount the servos to the servo tray using the servo

mounting screws provided with your servos. Use the tip

of your modeling knife to make small pilot holes in the

reinforcement board. See photo # 18 below.

Photo # 17

Photo # 18

PUSHROD INSTALLATION

TOOLS AND SUPPLIES REQUIRED

ITEMS REQUIRED

❑

{2} Threaded Pushrod Wires

❑

{2} Nylon Control Horns w/Backplates

❑

{2} Nylon Clevises

❑

# 0 Phillips Head Screwdriver

❑

Modeling Knife

❑

Wire Cutters

❑

Magnum Z-Bend Pliers

❑

Electric or Hand Drill

❑

1/16" Drill Bit

❑

Straight Edge Ruler

❑

Pen or Pencil

INSTALLING THE CONTROL HORNS

❑

1)

Using a modeling knife, cut one thin slot through

the middle of each molded recess in both the elevator and

the rudder. Cut the slot large enough for the ends of the

control horns to pass through.

❑

2)

Push one control horn through each slot. The

end of the elevator control horn should be on the bottom

of the elevator and the end of the rudder control horn

should be on the left side of the rudder.

❑

3)

Making sure the flat portion of the backplates

face away from the control surfaces, push the backplates

over the ends of the control horns until you hear them

"click" into place. See photo # 19 below.

Photo # 19

INSTALLING THE PUSHRODS

❑

4)

Using a modeling knife, carefully cut out the rud-

der pushrod exit hole (the back of the molded fairing) in

the top of the fuselage. Make the cutout large enough for

the pushrod wire to pass through easily.

❑

5)

Plug in your receiver, ESC, flight battery and

elevator and rudder servos. Turn on the radio system

and center both of the servos using the trim levers on the

transmitter.

❑

6)

Thread one nylon clevis onto each of the two

threaded pushrod wires. Thread the clevises on far enough

to leave room for adjustments later.

☛

Don't push the backplates too far down over the con-

trol horns or you might crush the foam.