Section 4

Auto-Zone Plus

4-22

Start-Up and Troubleshooting

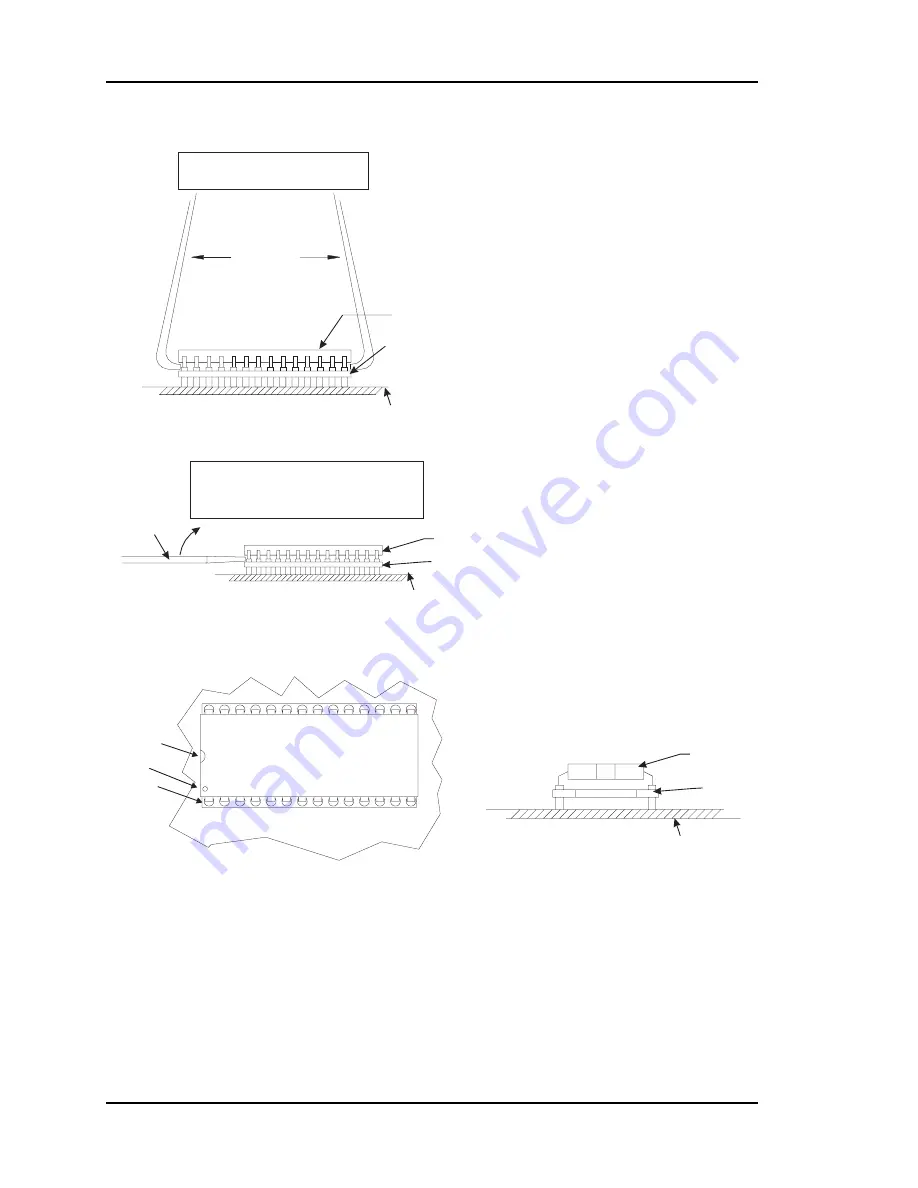

Figure 4-7:

Communication Driver Installation Information

Small Flathead

Screwdriver

Chip

Chip

Printed Circuit

Board

Printed Circuit

Board

Printed Circuit

Board

Chip

WARNING!

Direction Of Pull

Notch

Dot

Pin1

Be sure the chip you have selected to replace is a

socketed chip. Not all driver chips on the boards

are field replaceable. Only socketed chips may be

removed and replaced in the field. All other chips

that are not socketed will require sending the board

to the WattMaster factory for repair.

Once you have determined that the

chip needing replacement is indeed a socketed chip

please proceed in the following manner.

Remove the communications loop connector and

then the 24VAC power connector on the controller

before attempting to change any components.

will occur if components are removed or

installed with power applied.

If you are unsure how to safely remove the chip or

about the correct pin placement, please consult the

factory before proceeding.

Use extreme care to avoid inserting the screwdriver

or I.C. Puller under the socket. You must insert the tip

of the screwdriver or ends of the I.C. Puller between

the body of the chip and the chip socket.

Each chip

be installed with Pin 1 in the correct

location. Installing the chip “backwards” will in most

cases destroy the device when power is reapplied.

Pin 1 can be located by looking for the notch in the end

of the chip. Pin 1 on "some" chips is identified with a dot.

Be certain that

pins are lined up in the socket

before pressing the chip in. Failure to properly line

up the pins will result in damage to the chip.

This is a

common error -

Only after confirming that the chip has been correctly

installed with Pin 1 in the proper position and that the

pins are lined up and none are bent or out of the socket,

should communication or power wiring be reconnected

to the board. Tp prevent possible damage always

reconnect the power wiring first and then the

communication wiring.

If you try to

remove a chip that is not socketed it will destroy

the circuit board.

DAMAGE

Damage to the board caused by failure to correctly

remove or install the chip is not covered by the

WattMaster warranty.

MUST

ALL

VERY

BE CAREFUL.

Using I.C. Puller To Remove Socketed Chip

Using Screwdriver To Remove Socketed Chip

End View Of Socketed Chip Assembly

Top View Of Socketed Chip Assembly

I.C. Puller

Chip Socket

Chip Socket

Chip Socket

Gently Rock Chip Side To Side And Then

Lift Straight Up To Remove Chip From

Chip Socket.

Gently Lift The Chip On One End And Rock Chip

Back And Forth With Screwdriver As Shown.

Repeat This Process On The Other End Of Chip.

Alternate This Process On Both Ends Of Chip Until

The Chip Is Free From The Chip Socket.

firealarmresources.com

Summary of Contents for Auto-Zone Plus

Page 1: ...Design Installation And Operations Manual Plus System Revision 02B firealarmresources com...

Page 2: ...firealarmresources com...

Page 4: ...firealarmresources com...

Page 6: ...firealarmresources com...

Page 68: ...firealarmresources com...

Page 116: ...firealarmresources com...

Page 155: ...Auto Zone Plus Section 4 Start Up and Troubleshooting 4 37 Notes firealarmresources com...

Page 177: ...Auto Zone Plus Section 4 Start Up and Troubleshooting 4 59 Notes firealarmresources com...

Page 178: ...Section 4 Auto Zone Plus 4 60 Start Up and Troubleshooting Notes firealarmresources com...

Page 179: ...Auto Zone Plus Section 4 Start Up and Troubleshooting 4 61 Notes firealarmresources com...