Page 8

Turn off the cold water supply to the faucet by turning the angle stop valve completely off.

Open cold water sink faucet to relieve pressure.

Step 5

Step 6

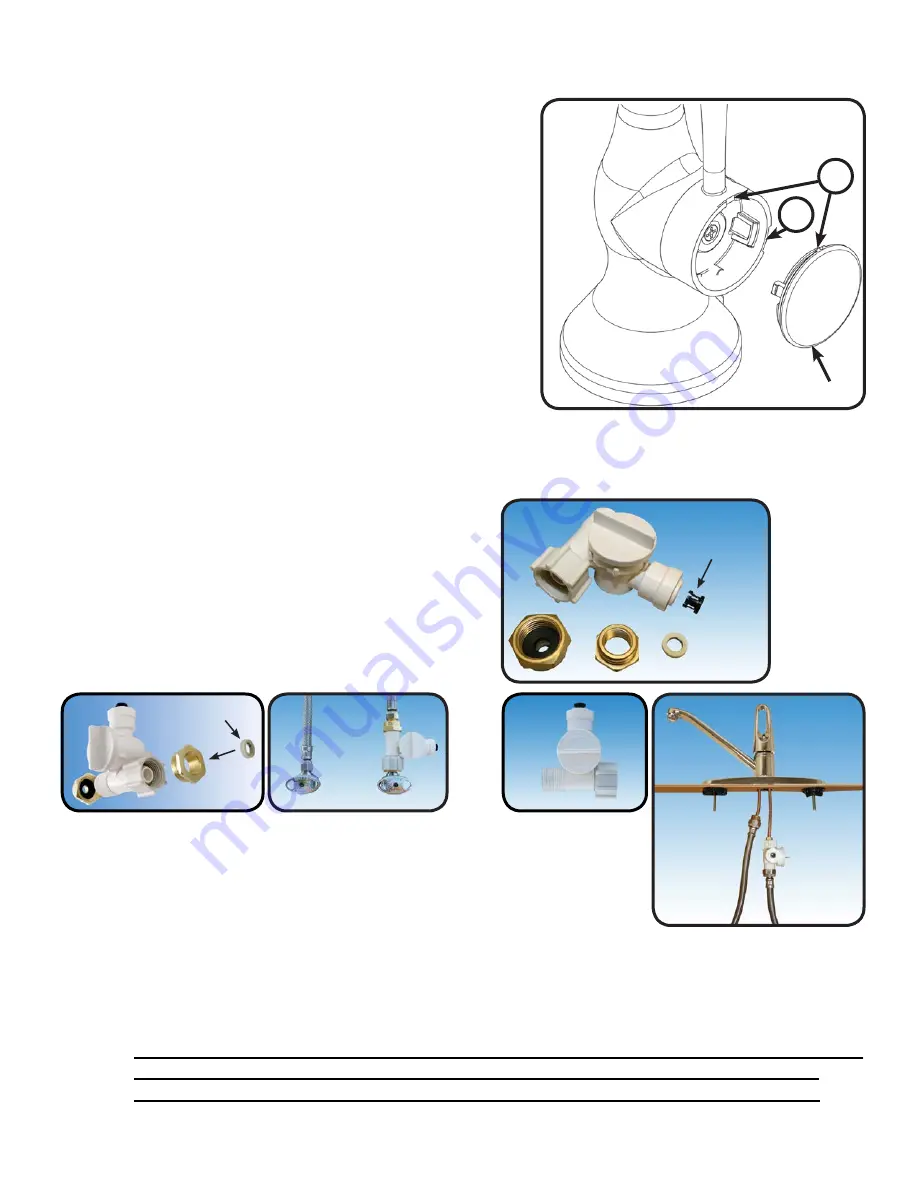

Choosing the configuration that fits your plumbing, attach the adapt-a-valve as illustrated in

the four photos above.

Adapt-a-Valve Installation

Do not use Teflon tape with the Adapt-a-Valve.

WARNING:

Caution:

Water supply line to the system must be from the cold water supply line only.

Hot water will severely damage your system.

3/8” Configuration

(With Brass Fittings)

* Insert White Washer

1/2” Configuration

(Without Brass

Fittings)

*

White

Washer

Hot

Supply

Cold

Supply

Hot

Supply

Cold

Supply

Verify contents prior to installation:

( 1 ) - Plastic Adapt-a-Valve with black collet

( 1 ) - Brass Adapter no washer

( 1 ) - Brass Adapter with black washer

( 1 ) - White rubber washer

Make sure that the black collet is installed in to the 1/4” opening on the Adapt-a-valve.

Don’t forget to install the white compression washer with the 3/8” configuration.

Brass adapter (A) does not need to be tightened with a wrench, only finger tight.

Black

Collet

A

TIPS:

A

White

Washer

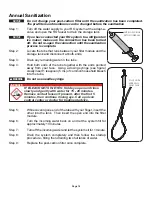

1. Turn the handle on the storage tank ball valve to the

“off” position and lower faucet handle to “on” position.

2. Remove the faucet handle cover at the slot -

(A)

.

Note: Water will dribble out of the spout, use caution

when handling the electronic components.

3. Slide the old battery out and replace with new battery.

Note: Once the battery is pushed into the clip a red and

blue light will flash indicating proper installation.

4. Replace cover assembly onto the faucet handle while

aligning the tab on the cover with the notch on

the faucets handle -

(B)

.

B

A

COVER

Faucet Indicator Battery Replacement