Benchmark 750-3000 Installation & Startup Manual

SECTION 2

– INSTALLATION

OMM-115_D

•

GF-200

•

5/9/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 36 of

126

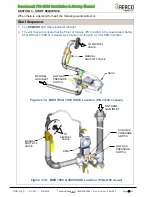

When mounting the sensor, it must be located on the North side of the building where an

average outside air temperature is expected. The sensor must be shielded from direct sunlight

as well as impingement by the elements. If a shield is used, it must allow for free air circulation.

2.11.2 AIR TEMP SENSOR

The

AIR TEMP SENSOR

terminal is used to monitor the air inlet temperature sensor (P/N

123449

). This input is always enabled and is a

“view only” input. It can be seen in the

AIR

TEMP

setting in the

Operating

menu (see Section 2.4:

OPERATING Menu,

item 4, of the

Benchmark 750

– 3000 Operation and Maintenance Guide

, OMM-0116 (GF-201). A resistance

chart for this sensor is provided in APPENDIX C of the same guide. This sensor is an active part

of the combustion control system and must be operational for accurate air/fuel mixing control.

2.11.3 O

2

SENSOR (+ &

–

)

The two

O

2

SENSOR

terminals (+ and

–) are used to connect an integrated oxygen sensor to

the I/O board. The O

2

concentration is displayed in the

Operating

menu after a 60 second warm-

up period. See Section 2.4:

OPERATING Menu,

item 13, of the

Benchmark 750

– 3000

Operation and Maintenance Guide

, OMM-0116 (GF-201).

2.11.4 SPARK SIGNAL (+ &

–

)

The two

SPARK SIGNAL

terminals (+ & -) connect to the spark monitor (P/N

61034

, also called

"AC Current transducer"), which monitors the current going to the ignition transformer (P/N

65085

. See Section 5.12 in the

Benchmark 750

– 3000 Operation and Maintenance Guide

,

OMM-0116 (GF-201) for more information. If the current is insufficient (too high or low) during

the ignition sequence, the controller will abort the ignition cycle. The controller will attempt up to

three ignition cycles. If the current is insufficient by the third try, the controller will shut down and

display a fault message.

2.11.5 ANALOG IN

The two

ANALOG IN

terminals (+ and

–) are used when an external signal is used to change

the setpoint (REMOTE SETPOINT mode) of the boiler.

Either a

4 to 20 mA/1

– 5 VDC

or a

0 to 20 mA/0

– 5 VDC

signal may be used to vary the set-

point or air/fuel valve position. The factory default setting is

4 to 20 mA/1

– 5 VDC

, however this

may be changed to

0 to 20 mA/0

– 5 VDC

in the

Configuration

menu; see Section 2.6:

CONFIGURATION Menu

, item 6, in the

Benchmark 750

– 3000 Operation and Maintenance

Guide

, OMM-0116 (GF-201).

If voltage rather than current is selected as the drive signal, a DIP switch must be set on the

PMC Board located inside the C-More Controller. Contact the AERCO factory for information on

setting DIP switches.

All supplied signals must be floating (ungrounded) signals. Connections between the source

and t

he boiler’s I/O board (Figure 2-11) must be made using twisted shielded pair of 18–22

AWG wire such as Belden 9841. Polarity must be maintained and the shield must be connected

only at the source end and must be left floating (not connected) at the Boiler’s I/O board.

Whether using voltage or current for the drive signal, they are linearly mapped to a 40°F to

240°F (4.4 to 116

°

C) setpoint or a 0% to 100% air/fuel valve position. No scaling for these

signals is provided