Benchmark 750-3000 Installation & Startup Manual

SECTION 4

– INITIAL START-UP

OMM-115_D

•

GF-200

•

5/9/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 69 of

126

PROPANE Combustion Calibration Instructions

29.

Use the Down ▼arrow key to lower the valve position to one of the following:

•

BMK 750P & 1000P:

80%

•

BMK 1500/2000/2500 DF & P:

70%

•

BMK 3000 DF & P:

85%

NOTE:

Remaining combustion calibration steps are performed using the

Combustion Cal

menu in

the C-More Controller. The combustion calibration control functions will be used to adjust

the oxygen level (%) at valve position percentages described in the steps below. These

instructions assume that the

inlet air temperature is between 50°F and 100°F (10°C

–

37.8°C)

. If NO

x

readings exceed the target values in Table 4-5, above, increase the O

2

level

up to 1% higher than the listed calibration range. Record the increased O

2

value on the

Combustion Calibration sheet.

30.

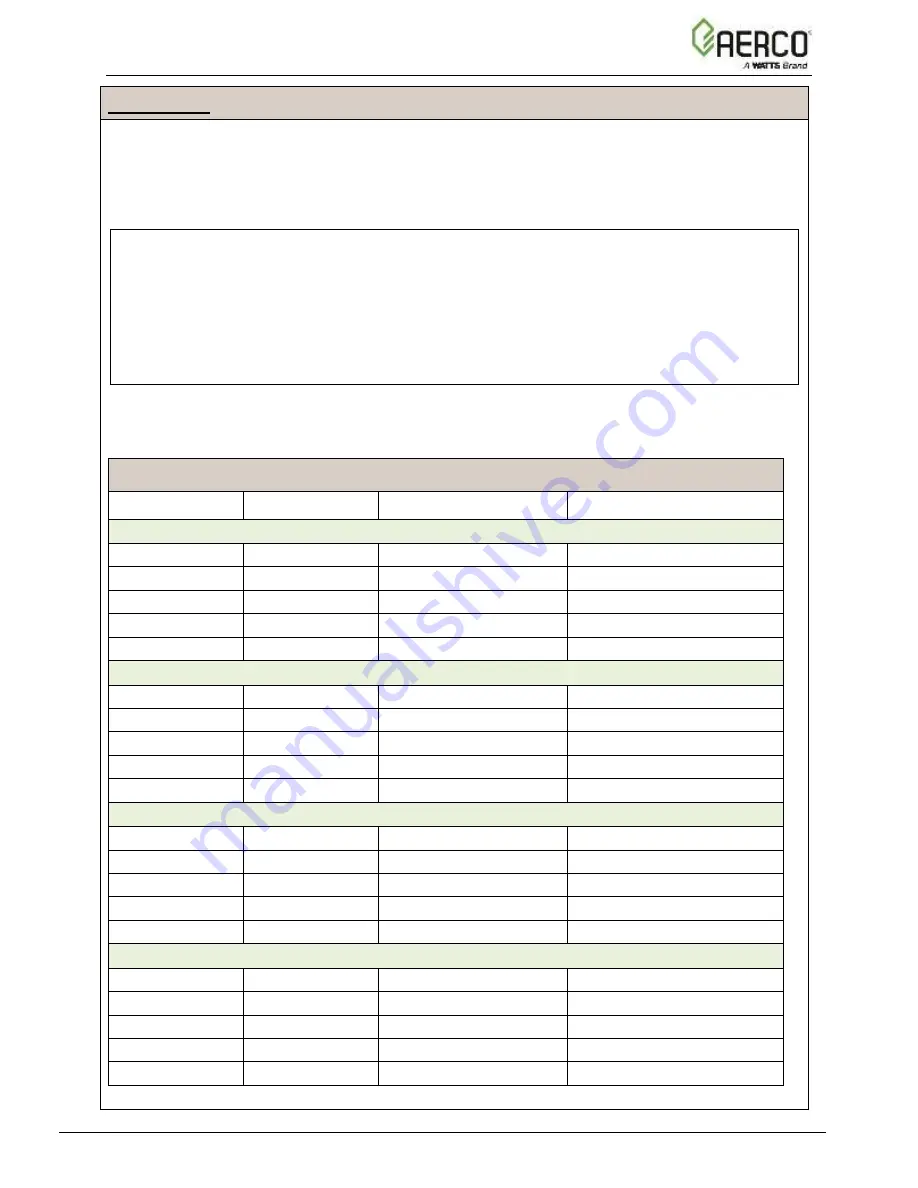

Repeat steps 21 through 25 for valve positions shown in Table 4-6. The oxygen (O

2

),

nitrogen oxide (NO

x

) and carbon monoxide (CO) should stay within the ranges shown

Table 4-6.

TABLE 4-6: Final Valve Positions

– PROPANE

Valve Position

Oxygen (O

2

) %

Nitrogen oxide (NO

x

)

Carbon Monoxide (CO)

BMK 750/1000

80%

5.5% ± 0.2%

<100 ppm

<150 ppm

60%

5.5% ± 0.2%

<100 ppm

<150 ppm

45%

5.5% ± 0.2%

<100 ppm

<150 ppm

30%

6.3% ± 0.2%

<100 ppm

<100 ppm

18%

5.5% ± 0.2%

<100 ppm

<100 ppm

BMK 1500

70%

5.2% ± 0.2%

<100 ppm

<150 ppm

50%

5.3% ± 0.2%

<100 ppm

<150 ppm

40%

6.2% ± 0.2%

<100 ppm

<150 ppm

30%

7.0% ± 0.2%

<100 ppm

<100 ppm

18%

8.5% ± 0.2%

<100 ppm

<100 ppm

BMK 2000

70%

6.5% ± 0.2%

<100 ppm

<150 ppm

50%

6.5% ± 0.2%

<100 ppm

<150 ppm

40%

6.5% ± 0.2%

<100 ppm

<150 ppm

30%

6.5% ± 0.2%

<100 ppm

<100 ppm

18%

5.5% ± 0.2%

<100 ppm

<100 ppm

BMK 2500

70%

5.4% ± 0.2%

<100 ppm

<150 ppm

45%

5.6% ± 0.2%

<100 ppm

<150 ppm

30%

6.0% ± 0.2%

<100 ppm

<100 ppm

22%

5.8% ± 0.2%

<100 ppm

<100 ppm

18%

6.0% ± 0.2%

<100 ppm

<100 ppm