Benchmark 5000-6000 Operation & Maintenance Manual

SECTION 6

– AERTRIM OPERATION

OMM-0118_B

•

GF-203

•

5/9/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 82 of 148

AERtrim Activation Instructions

1. Record the following information from the unit you wish to activate:

•

The unit’s

Alpha

– Year – Serial Number

, found on the unit’s code plate. For

example, for a unit built in 2017: N-17-0355.

•

O

2

Trim ID

, found in the

O2 Trim Key

in the C-

More Controller’s

Configuration

Menu

(item 33 in Section 2.6).

•

Fixed ID

, found in the

Fixed Key

in the

Configuration

Menu (item 34 in Section 2.6).

2. Contact AERCO Sales Administration with the recorded information. They will provide you

with a license key.

3. Once you have obtained the license key, navigate to the

O

2

Trim Key

in the

Configuration

menu and enter the key. The

O

2

Trim Menu

and AERtrim should automatically enable. If

the display does not change to the

O

2

Trim Menu

, something is wrong with the values

provided to obtain the key, or with the key itself. Double check your numbers and Contact

Sales Administration for another key.

4. The target O

2

%, O

2

upper range, and lower range are at default values but can be changed

as needed. However, you must enable the

Adjust O2 Trgts

option in the O

2

Trim menu

before you can change these settings.

6.3 OPERATION DETAILS

During operation, the AERtrim system will add or subtract a limited amount of voltage to the

value sent to the combustion air blower. The amount of voltage trim depends on the error

between the desired O

2

% (SP-setpoint) and the current reading of the O

2

sensor (PV-process

variable) and also on high and low limits of blower voltage. The total amount of corrective

voltage trim is limited by the controller to insure safe and reliable operation of the system.

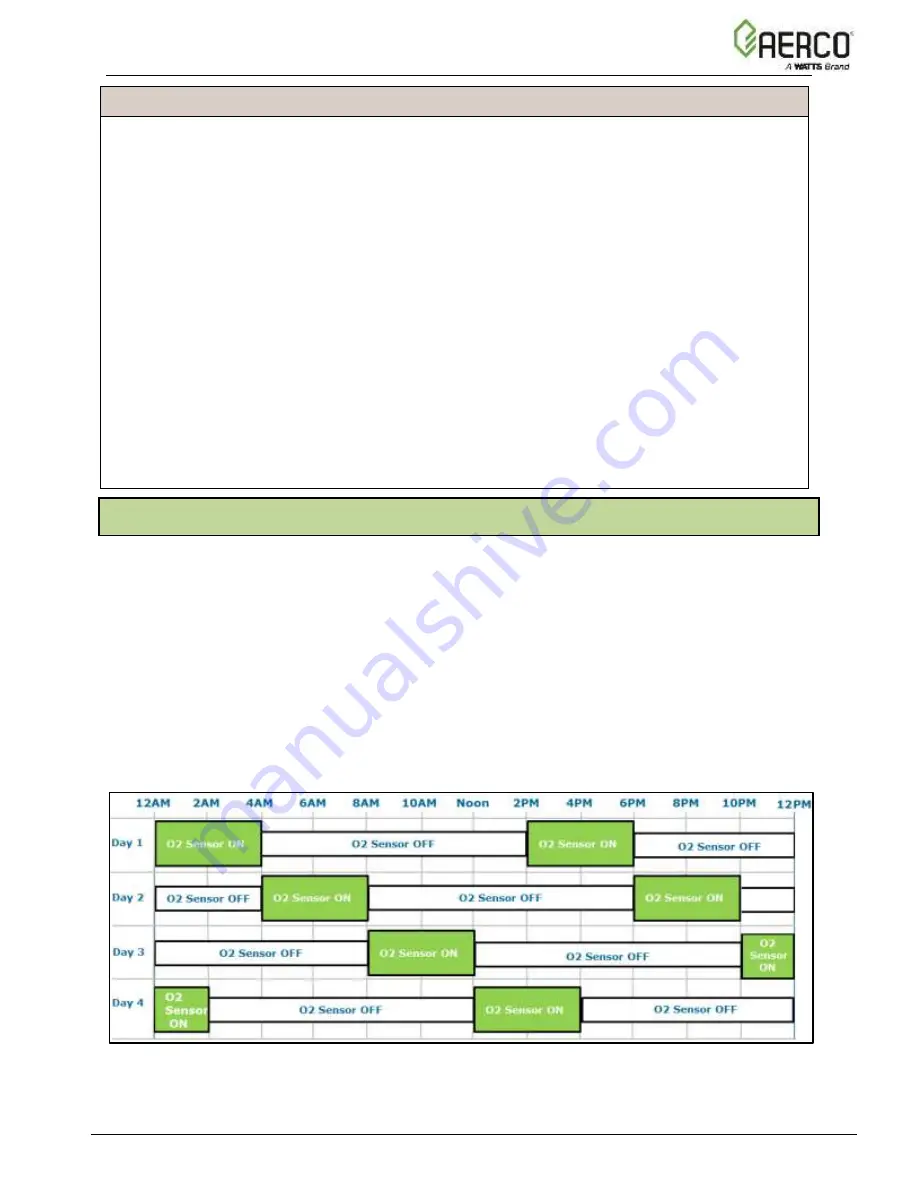

The AERtrim system has a rolling active/inactive operation based on 4 hours on / 10 hours off

sequence. Since this is a trim function and not an active control function, the trim activity can

make adjustments in the blower voltage calibration values on the 4/10 schedule to effectively

control the air/fuel mixture without continuous operation of the sensor. This method achieves

the objective for long term efficiency of boiler operation while maximizing the sensor life in the

boiler environment. The 14 hour cycle insures that the 4 hour on period will be active for any

hour of the day every four days as shown below.

Figure 6-2:

Active O

2

Sensor Cycle Coverage Chart