Benchmark Platinum-Edge: Operation-Service Manual

SECTION 9 – AERTRIM OPERATION

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 119 of 146

SECTION 9:

AERTRIM OPERATION

9.1 AERtrim INTRODUCTION

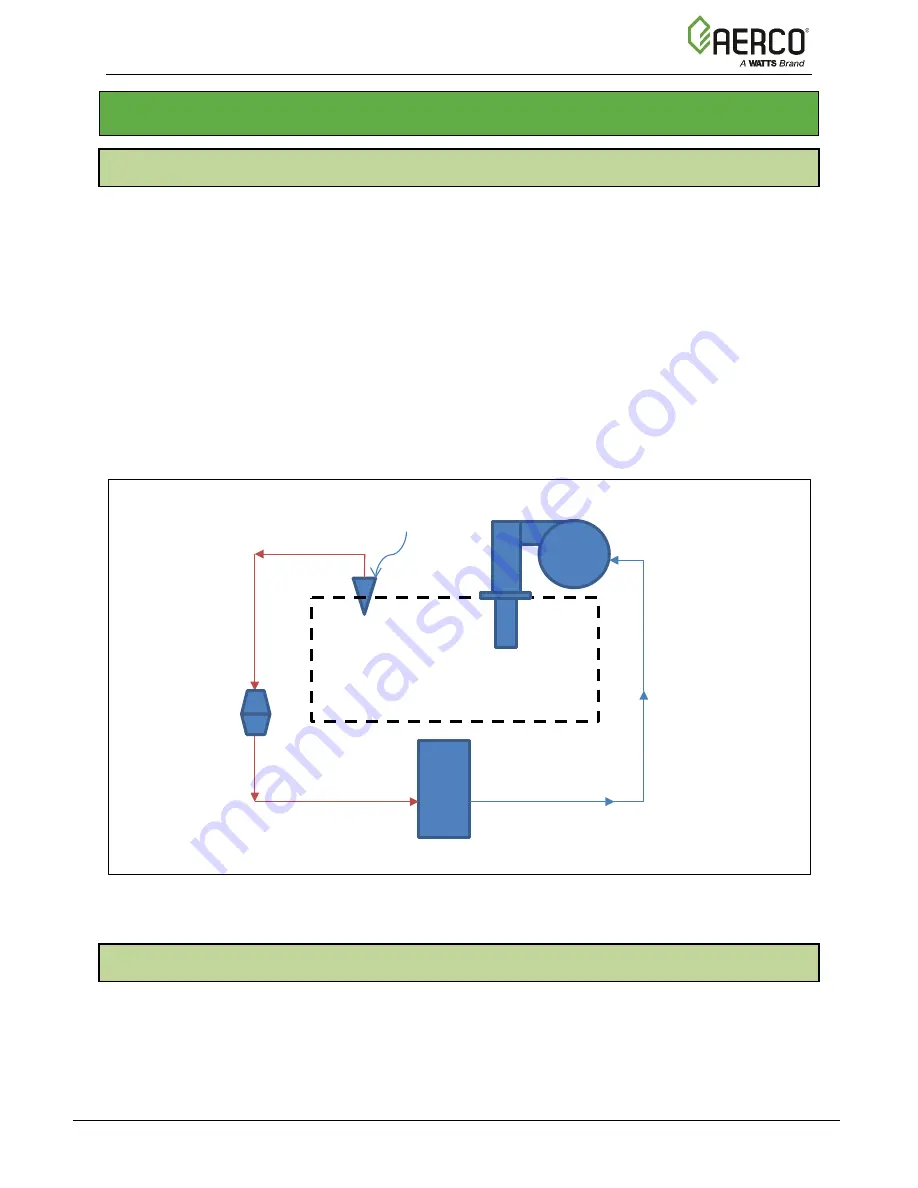

Advanced combustion control systems need to maintain precise air/fuel ratios to maximize

efficiency. Gas and oil-fired boilers often deviate from the ideal air-fuel ratio due to

environmental variations such as humidity, atmospheric pressure, filter dust loading, delivered

gas energy content and other factors. If the boiler is operating with fixed blower/damper

positions, the air/fuel ratio will normally vary within an acceptable level, but will not be fully

optimized for efficiency and reliability.

The AERtrim system is designed to measure and maintain an ideal air-fuel ratio in Benchmark

boilers, thus maximizing efficiency and reliability while minimizing emissions. It does this by first

measuring post combustion oxygen percentages inside the combustion chamber. This data is

fed through the Electronic Control Unit (ECU) which is connected to the Edge Controller inside

the boiler. If the oxygen readings are outside of preset or user defined values, the blower

voltage is changed in small increments until the reading falls within the ideal range.

A simplified representation of the system is shown in Figure 9-1.

Figure 9-1: Simplified AERtrim Diagram

9.2 AERtrim ACTIVATION

AERtrim is activated at the factory prior to shipping all Benchmark Platinum boilers. However, if

the Edge Controller is replaced for any reason, you must activate the AERtrim function by

entering an activation code, as described below. Note that the activation code for each unit is

unique, based on the unit’s serial number, and thus cannot be transferred to any other unit;

if

you have multiple units, you must take care to install the correct code on the correct unit

.

Combustion Chamber

O

2

Sensor

Sensor ECU

Edge Controller

Blower

Voltage Output

Oxygen Input

Burner

CanBus

CanBus