Benchmark Platinum-Edge: Operation-Service Manual

SECTION 6 – TROUBLESHOOTING

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 134 of 146

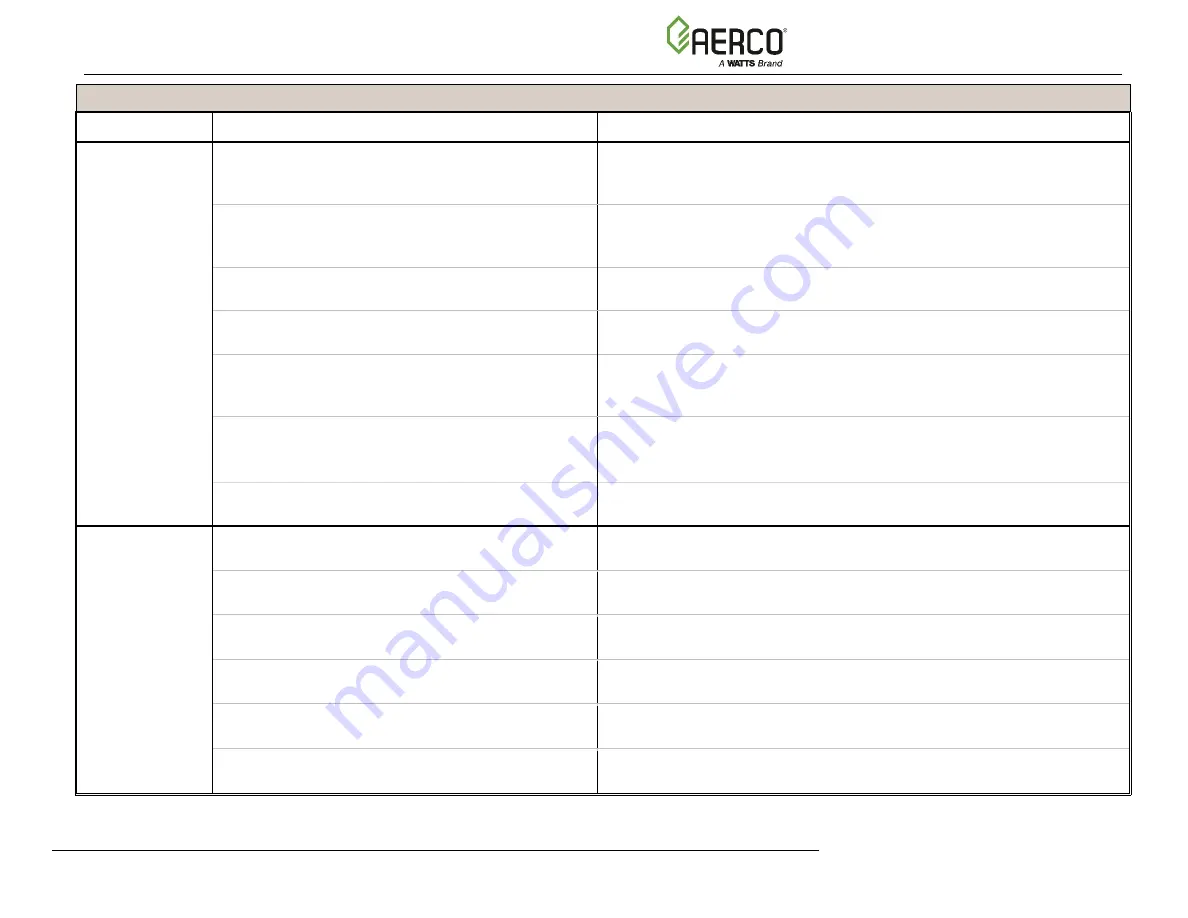

TABLE 10-1: Boiler Troubleshooting Procedures

Fault

Probable Causes

Corrective Action

AIRFLOW

FAULT

DURING

PURGE

1.

Blower not running or running too slow.

1.

Start the unit. If the blower does not run check the blower solid state

relay for input and output voltage. If the relay is OK, check the

blower.

2.

Defective Blocked Inlet switch.

2.

Start the unit. If the blower runs, turn off unit and check the Blocked

Inlet switch for continuity. Replace the switch if continuity does not

exist.

3.

Blockage in air filter or Blocked Inlet switch.

3.

Remove the air filter and Blocked Inlet switch and inspect for signs

of blockage. Clean or replace as necessary.

4.

Blocked blower inlet or inlet ductwork.

4.

Inspect the inlet to the combustion blower including any ductwork

leading up to the combustion blower for signs of blockage.

5.

No voltage to Blocked Inlet switch from Edge

Controller.

5.

During the start sequence, verify that 24 VAC is present between

each side of the switch and ground. If 24 VAC is not present, refer

fault to qualified service personnel.

6.

PROBABLE CAUSES from 3 to 12 for

AIRFLOW FAULT DURING IGNITION apply for

this fault.

6.

See CORRECTIVE ACTIONS for AIRFLOW FAULT DURING

IGNITION, items 3 to 12.

7.

Missing or improperly connected Blocked Flue

jumper.

7.

Check auxiliary box to be sure Blocked Flue input is jumpered and

properly connected.

AIRFLOW

FAULT

DURING RUN

1.

Blower stopped running due to thermal or

current overload.

1.

Check blower for signs of excessive heat or high current draw that

may trip thermal or current overload devices.

2.

Blocked Blower inlet or inlet ductwork.

2.

Inspect the inlet to the blower, including any ductwork leading up to

the combustion blower, for signs of blockage.

3.

Blockage in air filter or Blocked Inlet switch.

3.

Remove the air filter and Blocked Inlet switch and inspect for signs

of blockage, clean or replace as necessary.

4.

Defective Blocked Inlet switch.

4.

Verify that 24 VAC is present between each side of the switch and

ground. If 24 VAC is not present at both sides, replace switch.

5.

Combustion oscillations.

5.

Run unit to full fire. If the unit rumbles or runs rough, perform

combustion calibration.

6.

Probable causes from 3 to 16 for AIRFLOW

FAULT DURING IGNITION applies for this fault.

6.

See CORRECTIVE ACTIONS from 3 to 12 for AIRFLOW FAULT

DURING IGNITION.