Benchmark Platinum-Edge: Operation-Service Manual

SECTION 5 – SAFETY DEVICE TESTING

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 59 of 146

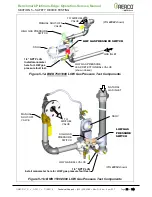

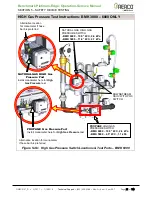

HIGH Gas Pressure Test Instructions: BMK 750 – 2500

Figure 5-3c: BMK 2500: HIGH Gas Pressure Fault Test

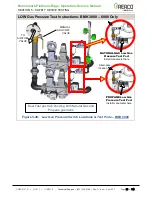

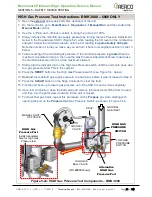

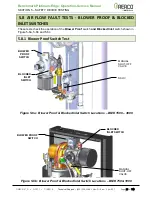

5.3.2 HIGH GAS PRESSURE TEST: BMK 3000 – 6000 Only

To simulate a high gas pressure fault, refer to Figure 5-4a and 5-4b and perform the following

steps:

HIGH Gas Pressure Test Instructions: BMK 3000 – 6000 ONLY

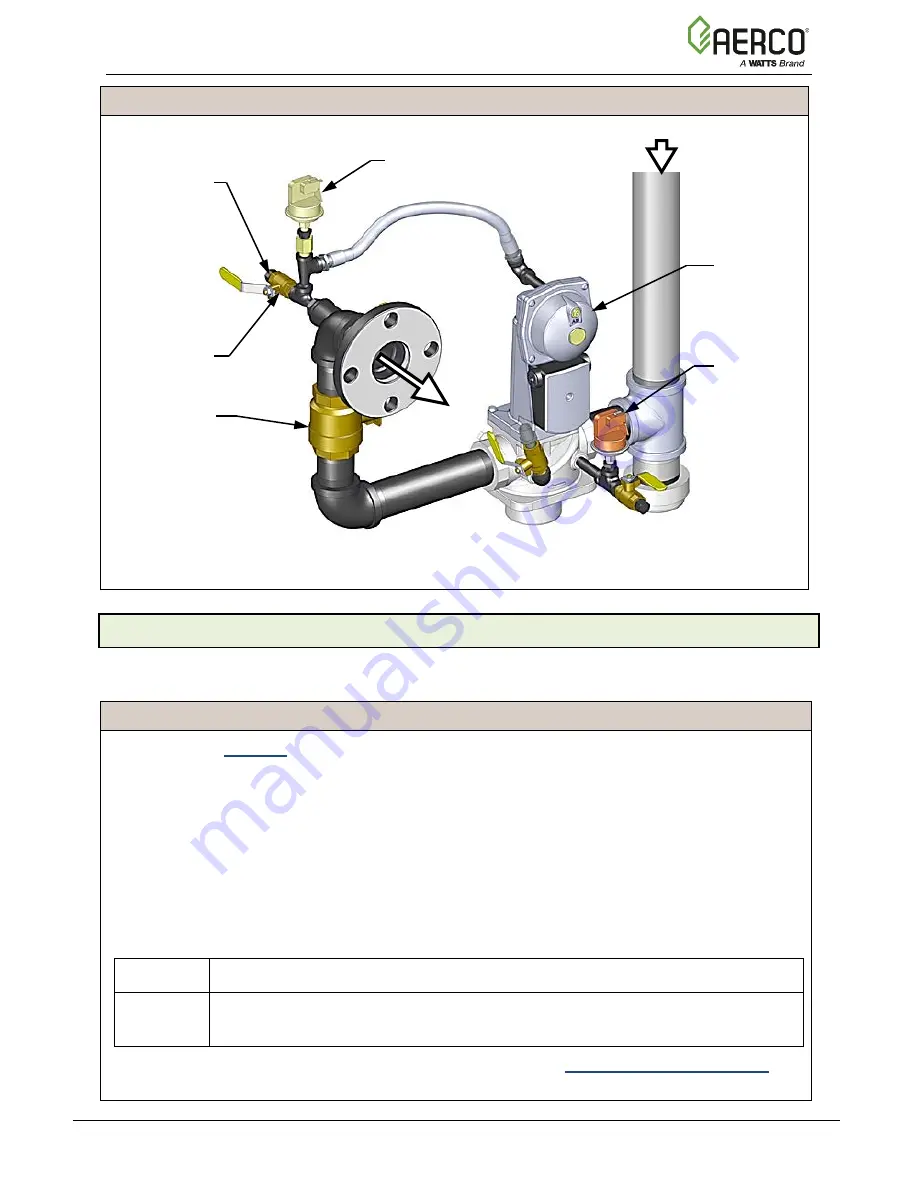

1. Shut off the

external

gas supply by closing the external gas supply ball valve.

2. Locate the port on the side of the

High Gas Pressure

switch and loosen the screw in the

port a few turns to open it.

Do not completely remove the screw.

Alternatively, you can

remove the 1/4 inch plug shown in Figure 5-4a and 5-4b and install a hose barb fitting in

that location.

3. Attach one end of the plastic tubing to the port or barb fitting and the other end to

a 0 – 16”

W.C. (0 – 4.0 kPa)

manometer.

4. Apply the reading of the manifold pressure taken in Step 21 of Section 4.4.1 (natural gas

units) or Step 21 of Section 4.4.2 (propane units) and plug it into the following formula,

which calculates the

maximum

allowable gas pressure:

BMK 3000

Natural Gas Pressure

______ x 1.5 = ______ max gas pressure

BMK 5000

& 6000

Natural Gas Pressure

______ x 1.5 = ______ max gas pressure

Propane Gas Pressure

______ x 1.5 = ______ max gas pressure

5. Remove the cover from the High Gas Pressure switch and

set the dial indicator to 20

(the

maximum).

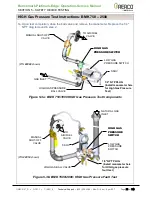

SSOV

TO

AIR/FUEL

VALVE

LOW GAS

PRESSURE

SWITCH

MANUAL

SHUT-OFF

VALVE

HIGH GAS

BALL VALVE

1/4” NPT

PLUG

(install

manometer

here for HIGH

GAS

PRESSURE

FAULT TEST)

NATURAL

GAS INLET

HIGH GAS PRESSURE

SWITCH

(P/N 22190 shown)