Benchmark Platinum-Edge: Operation-Service Manual

SECTION 7 – BOILER SEQUENCING TECHNOLOGY

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 83 of 146

7.3 BST Implementation Instruction

The instructions in the rest of this chapter refer to I/O board connections on the Benchmark

boilers. For an I/O board diagram and terminal connections, see Section 2.11.1 in

Benchmark

Platinum-Edge: INSTALLATION Manual

(OMM-0136, GF-210).

7.3.1 Option 1 Constant Setpoint: Direct Wired Header Sensor

OPTION 1

Instructions: Constant Setpoint with Direct Wired Header Sensor

Step 1:

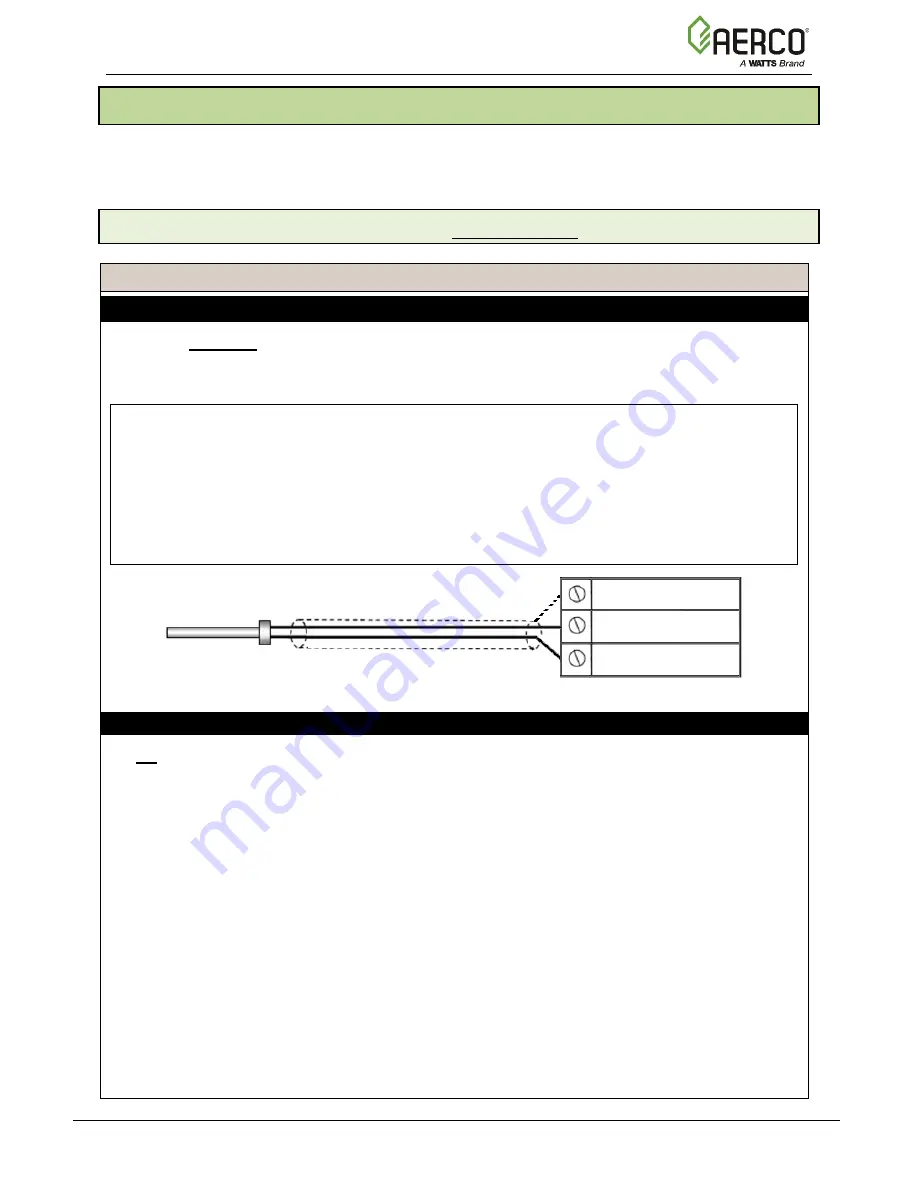

HEADER SENSOR WIRING – MANAGER Unit

1. On the

Manager

unit, connect the

Header Temperature Sensor

(P/N

24410

) to the I/O

board terminal strip

J3

, terminals

4

(

Supply Header

+

)

and

5

(

Supply Header

–).

2. Ground the shield to any

Shield

terminal on the I/O Board, such as Terminal 3 or 8.

NOTES:

•

The Header Sensor must be installed between 2 and 10 feet (0.61 and 3.1m)

downstream of the LAST boiler in the plant’s supply water header.

•

Shielded pair 18 - 22 AWG cable is recommended for header sensor wiring. There is no

polarity to be observed.

•

The ground for the shield is at the

Shield

terminal on the I/O the board. The sensor end

of the shield must be left free and ungrounded.

Step 2: OPTION 1 CONFIGURATION

On All Boiler:

1. Go to:

Main Menu

Advanced Setup

BST Cascade

Cascade Configuration

:

•

Set the

Unit Mode

parameter to

BST Client

.

2. Go to:

Main Menu

Advanced Setup

BST Cascade

Application Configuration

:

•

Set the

Unit Address

parameter to the communication address of the unit.

Continued on next page

HEADER TEMP SENSOR (P/N

24410

)

5 Supply Header –

3 Shield

I/O Board Strip J3

4 Supply