INSTALLATION

9

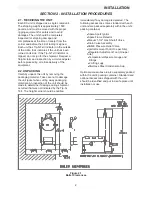

2.9 FLUE GAS VENT INSTALLATION

The AERCO Venting and Combustion Air Guide,

GF-1050, must be consulted before any flue or

inlet air venting is designed or installed.

Suitable, U/L approved, positive pressure,

watertight vent materials as specified in

AERCO’s GF-1050, must be used for safety and

UL certification. Because the unit is capable of

discharging low temperature exhaust gases, the

flue must be pitched back to the unit a minimum

of 1/4" per foot to avoid any condensate pooling

and to allow for proper drainage.

While the has a positive flue pressure during

operation, the combined pressure drop of vent

and combustion air systems must not exceed

140 equivalent feet of 0.81” W.C.. Fittings as

well as pipe lengths must be calculated as part

of the equivalent length. For a natural draft

installation the draft must not exceed - 0.25”

W.C..These factors must be planned into the

vent installation. If the maximum allowable

equivalent lengths of piping are exceeded, the

unit will not operate properly or reliably.

2.10 COMBUSTION AIR

The AERCO Venting and Combustion Air Guide,

GF-1050, MUST be consulted

before

any flue

or combustion supply air venting is designed or

started. Combustion air supply is a direct

requirement of ANSI 223.1, NFPA-54, and local

codes. These codes should be consulted before

a permanent design is determined.

The combustion air must be free of chlorine,

halogenated hydrocarbons, or other chemicals

that can become hazardous when used in gas-

fired equipment. Common sources of these

compounds are swimming pools, degreasing

compounds, plastic processing and refrigerants.

Whenever the environment contains these types

of chemicals, combustion air must be supplied

from a clean area outdoors for the protection

and longevity of the equipment.

The more common methods of combustion air

supply venting are outlined below. For

combustion air supply from ducting, consult the

AERCO GF-1050, Venting and Combustion Air

Guide.

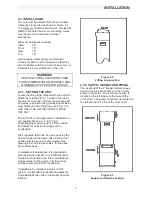

2.10.1 COMBUSTION AIR FROM

OUTSIDE THE BUILDING

Air supplied from outside the building must be

provided through two permanent openings. For

each unit these two openings must have a free

area of not less than one square inch for each

4000 BTUs input of the equipment or 250

square inches of free area. The free area must

take into account restrictions such as louvers

and bird screens.

2.10.2 COMBUSTION AIR FROM INSIDE

THE BUILDING

When combustion air is provided from within the

building, it must be supplied through two

permanent openings in an interior wall. Each

opening must have a free area of not less than

one square inch per 1000 BTUH of total input or

1000 square inches of free area. The free area

must take into account any restrictions such as

louvers.

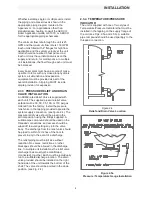

2.10.3 SEALED COMBUSTION

The KC Boiler is UL approved for 100% sealed

combustion application when installed properly.

When a sealed combustion air application is

installed, the sealed combustion air piping must

be deducted from the maximum allowable

discharge piping amounts. Each unit must have

a minimum 6" diameter connection made to the

special Inlet Air Adapter # GP-18917 available

from AERCO. This adapter bolts directly on to

the air inlet of the unit’s blower. See installation

instructions with adapter. All inlet air ducts must

be sealed air tight.

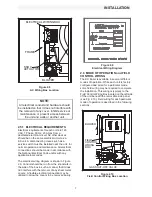

2.11 UNIT INITIAL FILL

Before filling the unit’s shell for the first time,

blow out all the connecting water and gas piping

and check thoroughly for leaks. Rinse all soap

suds from the gas piping with clean water. Do

not allow water to get on the control panel or

electrical connections. Check that all installation

procedures have been completed before filling

the unit.

The following steps should be followed when

filling the unit:

1. Close the unit’s drain valve.

2. Open the system return connection on

the

bottom of the unit.

3. Make certain that the system pressure

reducing fill valve is on to replenish pressure

in the system as the unit fills.

4. Using the pressure/temperature gauge,

supplied with the unit, as a guide, allow

pressure to slowly build up in the unit.

5. Slowly open either the manual vent valve or

the supply valve off its seat, allowing air to

vent from the unit’s shell.

Summary of Contents for AERCO KC Series

Page 51: ...TROUBLESHOOTING 41...

Page 65: ...APPENDIX C ix...

Page 72: ...APPENDIX F xvi...

Page 74: ...APPENDIX F xviii...

Page 76: ...APPENDIX G xx...

Page 77: ...APPENDIX G xxi...

Page 78: ...APPENDIX H xxii...

Page 79: ...APPENDIX H xxiii...

Page 80: ...APPENDIX H xxiv...