1726 North Ballard Road, Suite 1 - Appleton, WI 54911 - 920.991.9082

Technical Support 855.804.5774 - Parts@waupacaelevator.com

PTE10200-A

13 MAR 2018

W

E

Series:

008, 021, 022, 114, 115, 116, 118, 210

RED

BLK

YE

L

RED

BLK

YE

L

RED

BLK

YE

L

RED

BLK

YE

L

RED

BLK

YE

L

RED

BLK

YE

L

RED

BLK

YE

L

RED

BLK

YE

L

RED

BLK

YE

L

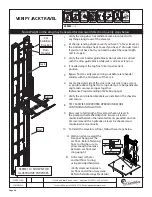

9

8

7

6

5

4

3

2

1

Dim

m

er

Blue/ Hot

Black

White

Yellow Dim Control

Red Dim Control

Black Dim Control

To Lights

120-240V

AC FEED

(Switched)

Change

Indicator

Battey

Test

Switch

Power Supply

DC Wiring

Battery

Back

Up

Blue/ Hot

Brown/ Neut

Brown/ Neut

Green & Yellow

LED Light Wiring

(With battery back up wiring)

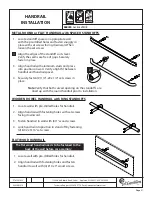

Strip the LED extension cord back to the desired length. Wire per LED light schematic and

national and local codes terminating one LED light per terminal.

Wire 2 LED lights to terminals 8 and 9 for emergency lighting. Wire per LED light schematic

and national/local codes.

Verify that all LED lights work and adjust the dimmer to desired brightness.

Secure the LED Light covers and power supply to the ceiling of the elevator car with provided

hardware

When the installation is complete press the test switch to test light operation. Allow up to 10

hours for a battery to fully charge before testing.

5.

WITH BATTERY BACK-UP WIRING

(OPTIONAL)

1.

2.

4.

3.

WARNING: DO NOT MIX AC AND DC WIRING. MAINTAIN BARRIER AS SHOWN BY THE DOTTED LINE

Input and output conductors are to be insulated for a minimum of 300V for all circuit connections.

CRUSH

HAZARD

CUTTING

HAZARD

CRUSH

HAZARD

CRUSH

HAZARD

FALLING

HAZARD

ANTI-

STATIC

ALERT

NOTE:

THERE ARE 9 SETS OF TERMINAL BLOCKS, EACH WITH 3 CONDUCTORS PER LIGHT. FOR SIMPLICITY, ONLY 1 SET IS SHOWN IN THIS

DIAGRAM. ALWAYS CONNECT ALL 3 WIRES (RED, BLACK, YELLOW), EVEN IF DIMMING IS NOT REQUIRED.

TO TURN LIGHTS ON AND OFF, SIMPLY ENERGIZE OR DE-ENERGIZE THE 120/240V AC INPUT TO THE EL2 POWER BOX.

ATTENTION: REMOVE ALL JUMPERS AS REQUIRED OUT OF THE LED LIGHT CONTROLLER BOX

Page 42