3 of 15

WX-501-0518 • 01.22

inserted and removed while there is still power to the rack.

3. Daisy-chain together all the cards you intend to use in your installation, using short RJ-11 jumper cables.

4. Connect the first Click 112/114 card to the SmartSensor via a Click 200 or Click 222 surge protector and a 60”

RJ-11 patch cord.

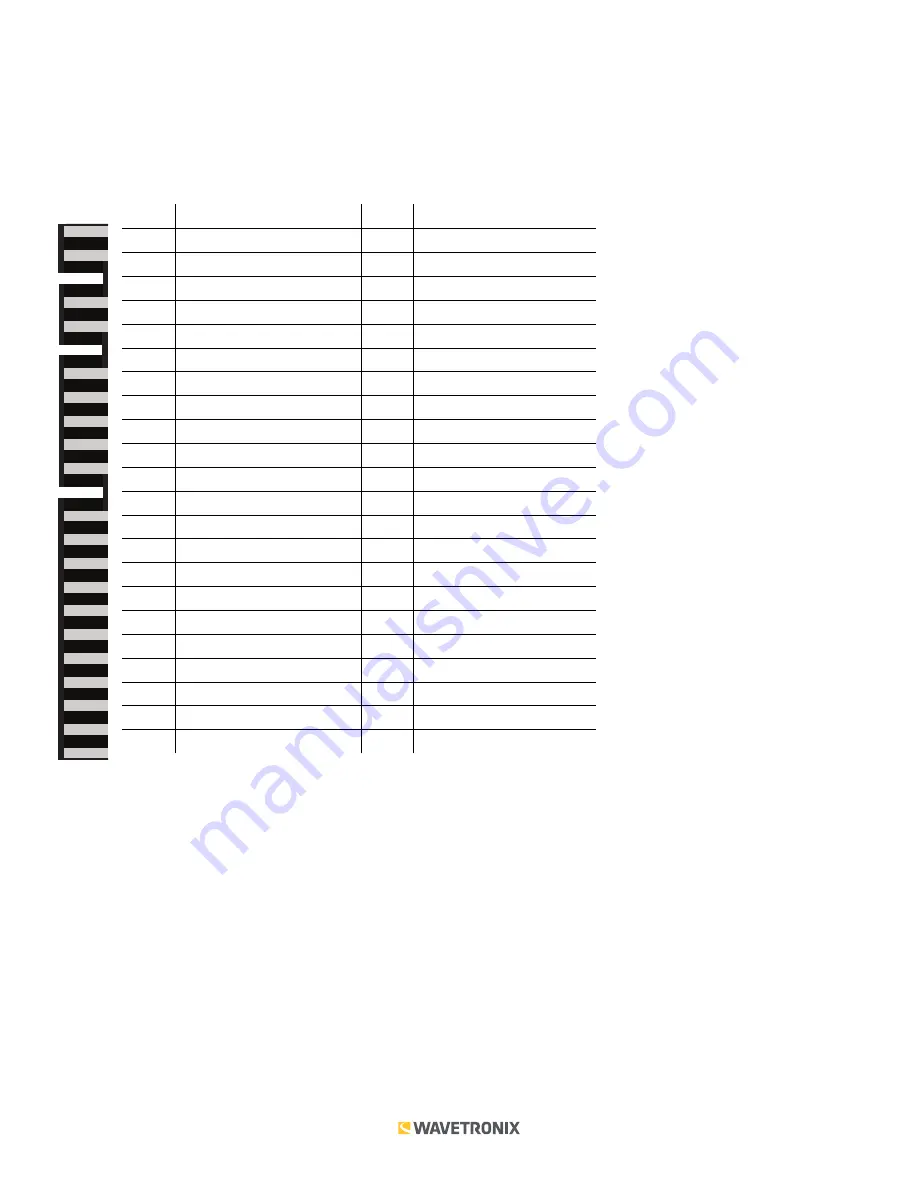

For your information, here is the pinout for the 44-pin edge connector on the back of the Click 112/114.

Pin

Back View Description Pin

Front View Description

1

No connection

A

-DC (common)

2

No connection

B

+DC (12–24 VDC)

3

No connection

C

No connection

4

No connection

D

No connection

5

No connection

E

No connection

6

No connection

F

Channel 1 output (+)

7

Channel 1 status output

H

Channel 1 output (–)

8

No connection

J

No connection

9

No connection

K

No connection

10

No connection

L

Chassis ground

11

No connection

M

No connection

12

No connection

N

No connection

13

No connection

P

No connection

14

No connection

R

No connection

15

No connection

S

Channel 3 output (+)*

16

Channel 3 status output*

T

Channel 3 output (–)*

17

No connection

U

No connection

18

No connection

V

No connection

19

No connection

W

Channel 2 output (+)

20

Channel 2 status output

X

Channel 2 output (–)

21

No connection

Y

Channel 4 output (+)*

22

Channel 4 status output*

Z

Channel 4 output (–)*

* Channels 3 and 4 exist only in the Click 114. In the Click 112, any pin marked

here as being associated with channel 3 or 4 will not be connected to anything.

Note.

For specific information on how to use the Click 112/114 with the SmartSensor Matrix, see the SmartSensor

Matrix User Guide.

Status Output Pins

The status output pins (7, 16, 20 and 22) signal based upon the NEMA TS-2 standard. In a TS-2 cabinet, the

detector rack BIU is meant to detect these signals, and send message frames over SDLC to the controller,

indicating which state the status pins are in.

The three potential status states of those pins are as follows:

■

Normal operation –

continuous low or on state

■

All channels currently in reset –

continuous high or off state

■

Detector unit in failsafe mode –

pulse width modulation with 50 milliseconds on time and 50 milliseconds off time