Installation and Mounting

[17]

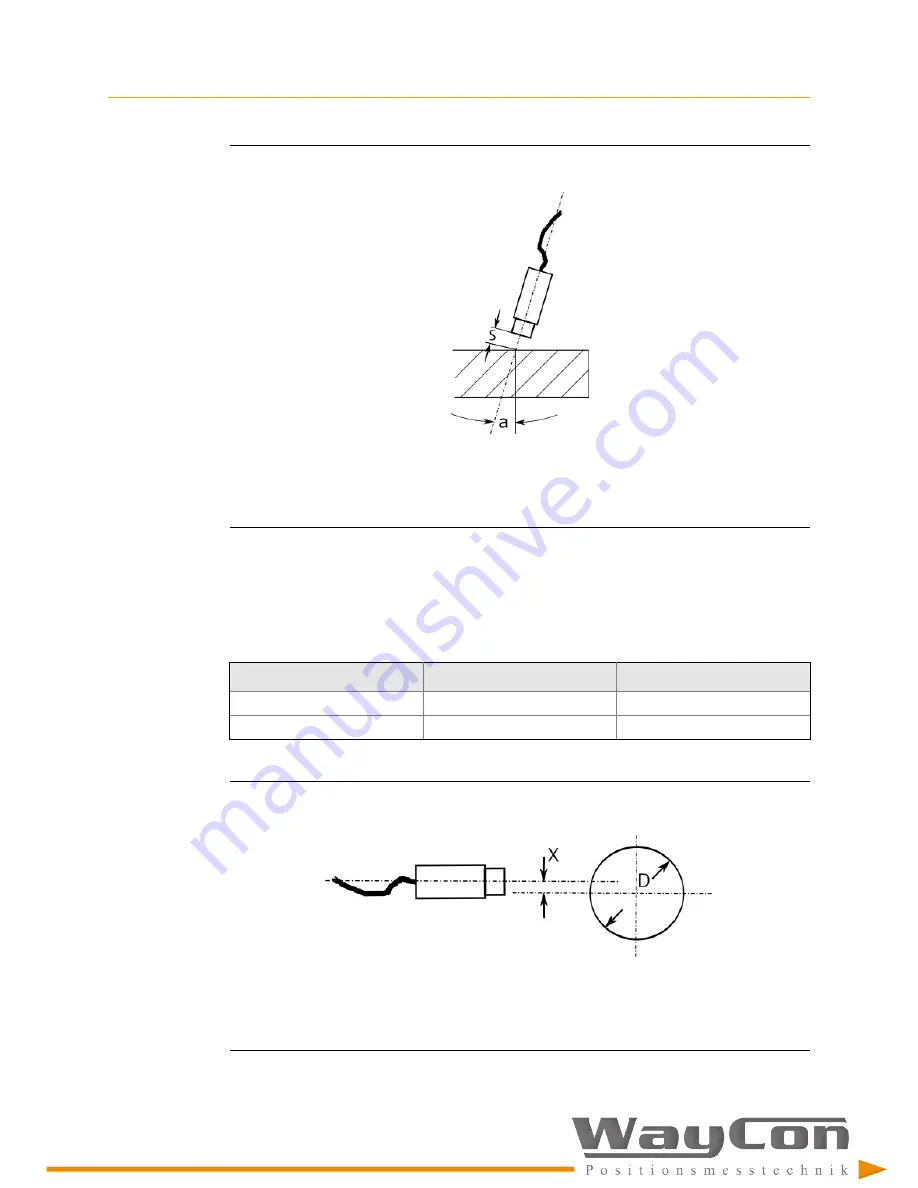

Figure 4-3: Maximum axial tilting

S: distance between measuring target and sensor head

a: maximal axial tilting angle < 2°

Maximum tangential offset

Ensure the maximum tangential offset matches the values in

shows

the definition of the tangential offset.

Table 4-1: Maximum tangential offset

Sensor type

Max. offset X

Shaft diameter D

EZ 105x

0.2 mm

≥ 20 mm

EZ 108x

0.5 mm

≥ 40 mm

Figure 4-4: Maximum tangential offset

X: maximal tangential offset

D: shaft diameter

Summary of Contents for EZ 105 Series

Page 4: ...Contents iv ...

Page 10: ...General 6 ...

Page 12: ...Safety instructions 8 Related information Environmental conditions ...

Page 16: ...Application and Design 12 ...