- 20 -

6. AB incremental output signals

Order code:

SSII and BISS

In addition to the absolute position information, MXS2 sensors can provide AB incremental signals through

the NPN open collector output circuit. They r5 VDC ±5% power supply with I

out

= 40 mA max. Thermal

and short-circuit protections are not provided.

Please note that the WBA2 magnetic tape is fitted with two tracks: an absolute track on one side and an

incremental track on the other side. Thus, you must strictly comply with the mounting direction! For complete

information refer to section

In the following table the main features of the incremental measuring system are listed for each order code

(see

). They concern the resolution (i.e. the distance between two following edges of A and B

channels), the minimum edge distance (i.e. the minimum spacing between two following signal edges at

output), the maximum counting frequency and the maximum travel speed.

Order code

Resolution

Min. edge distance *

Max. AB frequency

Max. travel speed

MXS2-...-50-...

50 µm

0.25 µs

73 kHz

7 m/s

MXS2-...-10-...

10 µm

0.25 µs

350 kHz

7 m/s

MXS2-...-5-...

5 µm

0.25 µs

580 kHz

7 m/s

MXS2-...-2-...

2 µm

0.25 µs

580 kHz

2.8 m/s

MXS2-...-1-...

1 µm

0.25 µs

580 kHz

1.4 m/s

* max. counting frequency = 4 MHz

Counting direction

►

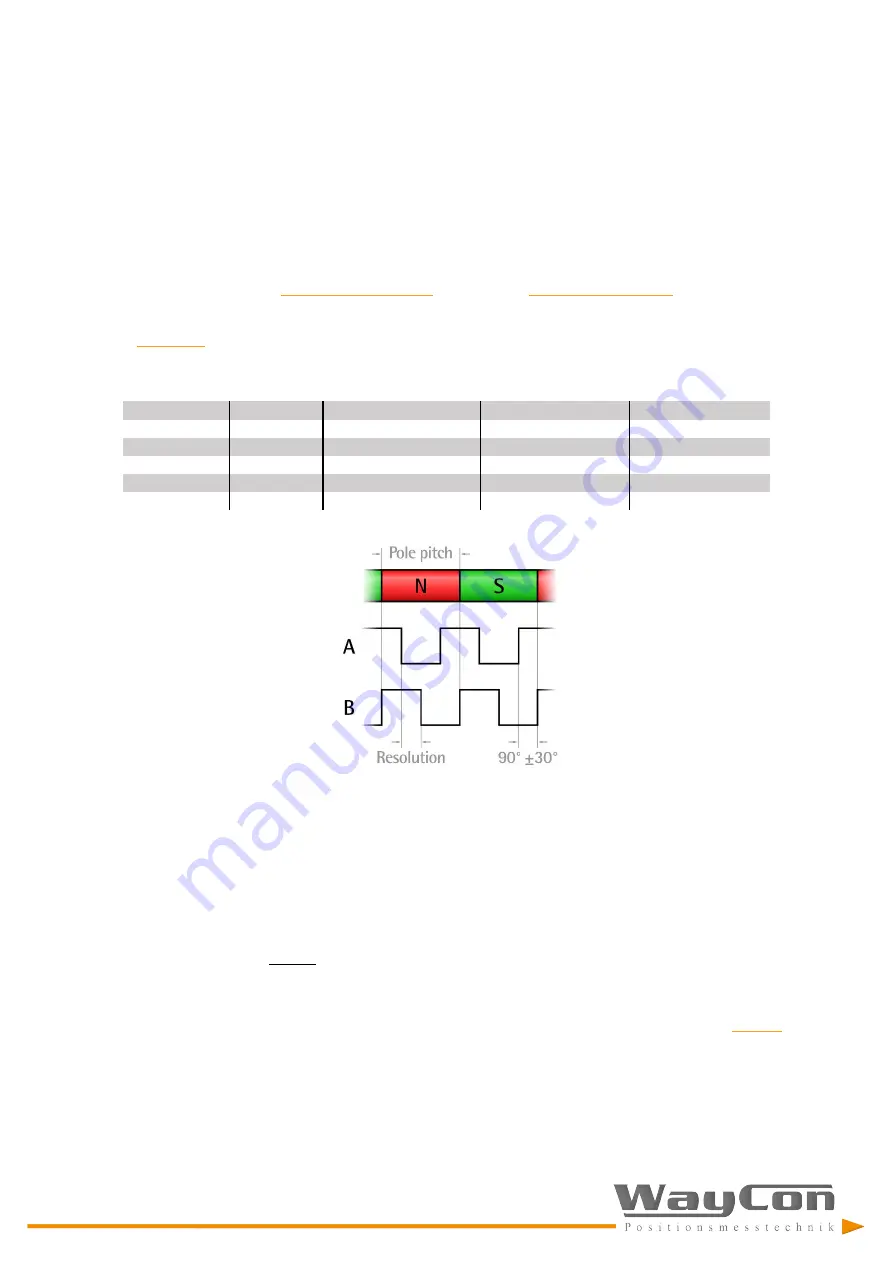

Please note that the incremental signals and their relationship with the pole pitch are represented

schematically in the Figure above. In the example the interpolation factor 4 is used. The real interpolation factor

results from the size (expressed in μm) of the pole pitch divided by the resolution of the specific sensor.

Example:

MXS2-SSII-50-...

Resolution = 50 µm

Pole pitch size = 2000 µm

Interpolation factor

Thus, in the case of the MXS2-SSII-50-… sensor, the system will provide 40 AB pulses per each pole.

NOTE:

Please note that the

Counting direction

parameter available in the BiSS-C interface (see on

affects the absolute position information, not the AB incremental signals.

=

2000

= 40

50

Summary of Contents for MXS2

Page 1: ...Magnetic Scale MXS2 Manual...