- 17 -

Enable preset / offset

It enables / disables the preset / offset functions. After having enabled the use of the functions you have to

choose whether to activate the preset or the offset in the

Set preset / offset

parameter. Then to activate a new

value, set it next to the Preset / Offset register and send the

Save and activate Preset / Offset

command (set

“02” in the register 48).

Default = 0 (

enable

)

Output code

The sensor provides the absolute position information in the desired code format: GRAY (0) or BINARY (1).

Default = 1 (

Binary

)

Counting direction

The

standard counting direction

is to be intended with sensor moving as indicated by the arrow in Figure 1.

This parameter allows to reverse the counting direction. In other words, it allows the count up when the sensor

moves in the reverse of the standard direction, i.e. in the opposite direction to the one shown by the arrow in

Figure 1. It is possible to choose the following options: STANDARD (0) and INVERTED (1). When the counting

direction is set to STANDARD, the position information increases when the sensor moves according to the

arrow in Figure 1. When the option INVERTED is set, the position information increases when the sensor moves

in reverse of the standard direction, i.e. in the opposite direction to the one shown by the arrow in Figure 1.

Default = 0 (Standard)

NOTE:

The

Counting direction

parameter affects the absolute position information, not the AB incremental

signals.

The new setting will be active immediately after transmission. Use the

Save parameters on EEPROM

function

(set “01” in the register 48) to store the new value.

Configuration register default value =

20h

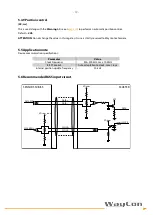

5.4.5 Absolute resolution

[4D, ro]

It allows to read the resolution of the absolute sensor.

32hex: Resolution = 50 μm

(max position = 03 FF FFh, 18 bits)

0Ahex: Resolution = 10 μm

(max position = 0F FF FFh, 20 bits)

05hex: Resolution = 5 μm

(max position = 1F FF FFh, 21 bits)

02hex: Resolution = 2 μm

(max position = 3F FF FFh, 22 bits)

01hex: Resolution = 1 μm

(max position = 7F FF FFh, 23 bits)

5.4.6 Preset / Offset

[51...53, rw]

This function is available only if the

Enable preset / offset

parameter in the Configuration register is set to

ENABLE. Furthermore, it has a double function depending on whether the

Set preset / offset

parameter in the

Configuration register is set to PRESET or OFFSET. In the first case (

Set preset / offset

= PRESET) the Preset /

Offset register is used to set the preset value. In the second case (

Set preset / offset

= OFFSET) the Preset /

Offset register is used to set the offset value.

ATTENTION:

Activate the preset / offset value only when the device is not moving.

Summary of Contents for MXS2

Page 1: ...Magnetic Scale MXS2 Manual...