Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the Find a Dealer section online at www.Wayne-Dalton.com

Weather seal

Level

Bottom section

Wooden shims

(If necessary)

vertical Tracks

Tools: Power Drill, 3/16” Drill bit, 7/16” Socket driver, Tape measure,

12

IMPORTANT:

IF YOuR DOOR IS TO BE INSTALLED PRIOR TO A FINISHING CONSTRuCTION

OF THE BuILDING’S FLOOR, THE VERTICAL TRACKS AND THE DOOR BOTTOM SECTION

ASSEMBLY SHOuLD BE INSTALLED SuCH THAT WHEN THE FLOOR IS CONSTRuCTED, NO

DOOR OR TRACK PARTS ARE TRAPPED IN THE FLOOR CONSTRuCTION.

IMPORTANT:

THE TOPS OF THE VERTICAL TRACKS MuST BE LEVEL FROM SIDE TO SIDE.

IF THE BOTTOM SECTION WAS SHIMMED TO LEVEL IT, THE VERTICAL TRACK ON THE

SHIMMED SIDE MuST BE RAISED THE HEIGHT OF THE SHIM.

Position the left hand vertical track assembly / wall angle track assembly over the track

rollers of the bottom section. Make sure the counterbalance lift cable is located between the

track rollers and the door jamb. Drill 3/16” pilot holes into the door jamb for the lag screws.

FOR FLAG ANGLE TRACk ASSEMBLIES:

Loosely fasten jamb brackets and flag angle to the jamb using 5/16” x 1-5/8” lag screws, as

shown.

FOR WALL ANGLE TRACk ASSEMBLy:

Loosely fasten wall angle to the jamb using 5/16” x 1-5/8” lag screws, as shown.

IF yOu HAvE 2” vERTICAL TRACkS:

Tighten lag screws, securing the bottom jamb bracket/bottom slot to jamb, maintain 3/8” to

5/8” spacing, between the bottom section and vertical track.

IF yOu HAvE 3” vERTICAL TRACkS:

Tighten lag screws, securing the bottom jamb bracket/bottom slot to jamb, maintain 1/2” to

3/4” spacing, between the bottom section and vertical track.

Hang counterbalance lift cable over flag angle/wall angle. Repeat same process for other

side.

2”

Vertical track

spacing (3/8” to 5/8”)

3”

Vertical track

spacing (1/2” to 3/4”)

Bottom

section

Floor

Track roller

Wallangle

track

assembly

Jamb

bracket

Riveted track

flag angle

shown

Riveted

flag angle

5/16” x 1-5/8”

Lag screws

Bottom

section

Track

rollers

Vertical track

assembly

Flag

angle

Lag

screw

locations

Fully Adjustable

flag angle

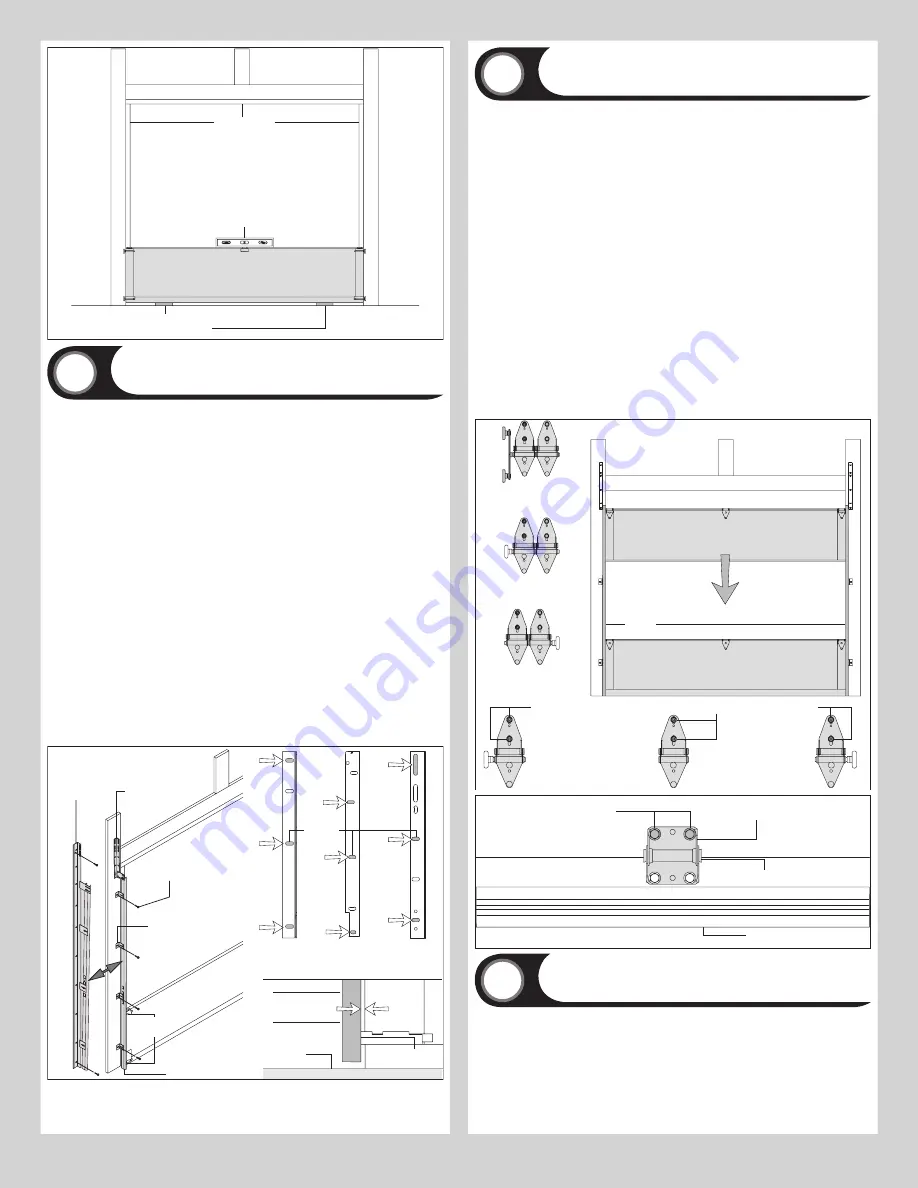

Stacking Sections

Tools: Power drill,7/16” Socket driver

13

NOTE:

Make sure graduated end and center hinges are flipped down, when stacking another

section on top.

With assistance, lift intermediate I (second) section and guide the track rollers / tandem

rollers into the vertical tracks. Lower section until it is seated against bottom section. Keep

sections aligned. Repeat same process for other sections, except top section.

FOR GRADuATED END HINGES AND CENTER HINGES:

Starting with the outer graduated end hinges, flip the upper hinge leaf up and secure to the

section using (2) 1/4”-20 x 1-7/8” carriage bolts and (2) 1/4”–20 flange hex nuts. Repeat

same process for the center hinges.

If you have double graduated end hinges, flip the inner upper hinge leaf up and use it as a

template. Mark and pre-drill (2) 1/8” pilot holes, 1” deep into the section using a 1/8” drill bit.

Attach the upper hinge leaf to the section using (2) 1/4”-14 x 1” lag screws. Repeat same

process for other side.

IF yOu HAvE HALF CENTER HINGES:

Flip the upper hinge leaf up and use it as a template. Mark and pre-drill (2) 1/8” pilot holes,

1” deep into the section using a 1/8” drill bit. Attach the upper hinge leaf to the section using

(2) 1/4”-14 x 1” lag screws. Repeat same process for other half center hinges.

IMPORTANT:

BE ExTREMELY CAREFuL NOT TO DRILL THRu THE SECTION. ONLY DRILL 1”

DEEP.

IMPORTANT:

PuSH & HOLD THE HINGE LEAFS SECuRELY AGAINST THE SECTIONS WHILE

SECuRING WITH 1/4”-20 x 1-7/8” CARRIAGE BOLTS AND 1/4”–20 FLANGE HEx NuTS.

THERE SHOuLD BE NO GAP BETWEEN THE HINGE LEAFS AND THE SECTIONS.

Center

hinge(s)

Left single

graduated end

hinge with

typical short

stem track roller

Right single

graduated end hinge

with typical short

stem track roller

(2) 1/4”-20 x 1-7/8” Carriage bolts and (2) 1/4”-20 Flange hex nuts

Intermediate I section

Bottom section

Vertical

tracks

Left double graduated

end hinge with typical

long stem track roller

Typical graduated end

hinge with typical long

stem tandem track roller

Right double graduated

end hinge with typical

long stem track roller

(2) 1/4”-14 x 1”

Lag screws

Long strut (if applicable)

Typical sections shown

Half center hinge

Upper hinge leaf

Top Section

Tools: Hammer, Step ladder, Tape measure

14

Place the top section in the opening. Temporarily secure the top section by driving a nail into

the header near the center of the door and bending it over the top section. Now, flip up the

graduated end hinge and center hinge leaves, hold tight against section, and fasten center

hinges first and end hinges last (refer to step, Stacking Sections). Vertical track alignment

is critical. For 2” track, position flag angle/wall angle between 1-11/16” (43 mm) to 1-3/4”

(44 mm) from the edge of the door; tighten the bottom lag screw. For 3” track, position flag

angle/wall angle between 2-3/16” (56 mm) to 2-1/4” (57 mm) from the edge of the door;

tighten the bottom lag screw.

Flag angles/wall angles must be parallel to the door sections. Repeat same process for other

10

Summary of Contents for 105/110

Page 21: ......