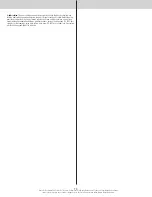

Door Arm Hookup

Tools: Needle nose pliers

At the center of the top section, measure horizontally from the top of center hinge to the bottom

of strut. using that dimension, measure and cut (2) pieces of perforated angles. Assemble the

(2) pieces together using (2) 3/8” bolts and nuts (supplied by others). Now, secure to the top

section using carriage bolts and nuts (supplied by others), thru bolt both the perforated angles to

the top section, as shown.

Align the door arm with hole with one of the holes in the perforated angles. Secure the door

arm to the perforated angle using (1) 5/16” – 18 x 1” hex head bolt and (1) 5/16” – 18 lock nut

(supplied by others), as shown.

Top

section

(2) Perforated

angles

Carriage bolt

and nuts

(supplied by

others)

Typical

door arm

Strut

Center hinge

(1) 5/16” Hex bolt

and lock nut

(supplied by others).

(2) 3/8” Hex bolt

and lock nut

(supplied by others).

Lift Handles

Tools: Power drill, 1/8” Drill bit, Tape measure

NOTE:

Lift handles must be lined up vertically.

Bottom Section:

Locate the exterior center stile or center most stile on the bottom section.

NOTE:

For flush doors, find the center most stile by locating the center most hinge.

using the bottom hole of the lift handle, measure up 3” from the bottom of bottom section. Mark

the hole locations and drill (2) 9/32” dia. holes through the bottom section. On the outside of

the door, insert (2) 1/4” - 20 x 2 1/2” carriage bolts (black head) into the outside lift handle and

insert the assembly into the (2) pre-drilled holes in the bottom section. From the inside, slide the

(2) holes in the inside lift handle over the stems of the carriage bolts. Secure the outside and

inside lift handle to the bottom section with (2) 1/4” – 20 flange hex nuts.

Intermediate I Section:

Locate the exterior center stile or center most stile on the Intermediate I section. Mark a vertical

line on the section at that point.

NOTE:

Some Garage Doors may require both lift handles to be installed on bottom section. If

your bottom section height is 28” or 29”, install both lift handles onto the bottom section. Install

bottom lift handle per above instructions, then install the second lift handle a Minimum of 20”

and a Maximum of 30” above the bottom lift handle.

Measure up 4” from the bottom of the Intermediate I section. using this measurement as a

guide, position the bottom hole of the lift handle bottom at the mark. Make a mark at the top

hole of the lift handle. This should give you a Minimum of 20” and a Maximum of 30” between

the lower lift handle and the middle of the top lift handle. If needed, reposition the lift handle to

stay within the Minimum and Maximum dimensions, as stated above.

using the lift handle as a template, mark the hole locations and drill (2) 9/32” dia. holes through

the section. On the outside of the door, insert (2) 1/4” - 20 x 2 1/2” carriage bolts (black head)

into the outside lift handle and insert the assembly into the (2) pre-drilled holes in the section.

From the inside, slide the (2) holes in the inside lift handle over the stems of the carriage bolts.

Secure the outside and inside lift handle to the section with (2) 1/4” – 20 flange hex nuts.

Lift

handle

Lift

handle

Center

hinge

Bottom

section

Intermediate I

section

Strut

(2) 1/4” - 20 x 2 1/2”

Carriage bolts and (2) 1/4” – 20

Flange hex nuts

(2) 1/4” - 20 x 2 1/2”

Carriage bolts and (2) 1/4” – 20

Flange hex nuts

3”

Pull Down Rope

Tools: Power drill, 1/8” Drill bit, Tape measure

WARNING

WARNING

DO NOT INSTALL PuLL DOWN ROPE ON DOORS WITH OPERATORS. CHILDREN

MAy BECOME ENTANGLED IN THE ROPE CAuSING SEvERE OR FATAL INJuRy.

Measure and mark the jamb approximately 48” to 50” (1220 to 1270 mm) from floor on the

right or left side of jamb. Drill 1/8” pilot hole for no. 6 screw eye. Tie the pull down rope to the

no. 6 screw eye and to the bottom corner bracket, as shown.

Typical bottom

corner bracket

Pull down

rope

No. 6 Screw eye

Pull

down

rope

48” to 50”

From floor

17

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the Find a Dealer section online at www.Wayne-Dalton.com

optional Installation

Summary of Contents for 105/110

Page 21: ......