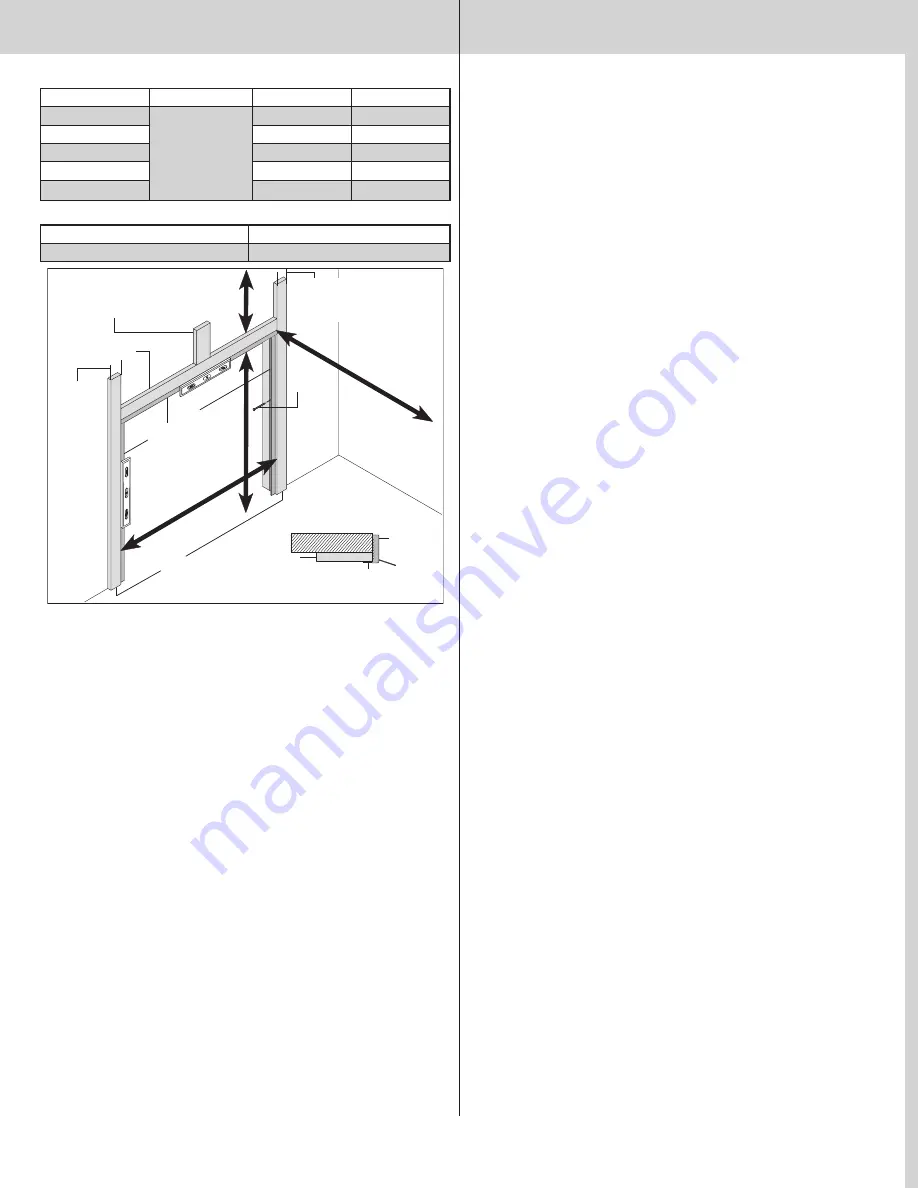

Door Height

Track

Manual Lift

Motor Operated

6’0” to 7’0”

15” Radius

102” (2591 mm)

125” (3175 mm)

7’1” to 8’0”

114” (2896 mm)

137” (3480 mm)

8’1” to 9’0”

126” (3200 mm)

168” (4267 mm)

9’1” to 10’0”

138” (3505 mm)

168” (4267 mm)

10’1” to 12’0”

162” (4115 mm)

*

HEADROOM REquIREMENTS

Track Type

Space Needed

6” LHR

9” (229 mm)

Weatherstrips

Level header

Finished

Door width

Jambs

Backroom

Plumb

jambs

Finished

Door

Height

Nail

Headroom

Header board 2”x 6”

lumber preferred

Suitable mounting surface

2”x 6” lumber minimum

Weather-

strips

Jamb

1/8” to 1/4”

Min. side

room

clearance for

2” track is

3-1/2” (89

mm).

Min. side

room

clearance for

3” track is

4-1/2” (114

mm).

Min. side room clearance for 2”

track is 3-1/2” (89 mm).

Min. side room clearance for 3”

track is 4-1/2” (114 mm).

6

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the Find a Dealer section online at www.Wayne-Dalton.com

Summary of Contents for 105/110

Page 21: ......