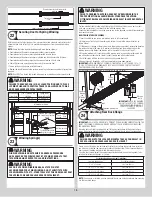

End stile

End stile

Lock or

Intermediate

section

#1Center

hinge(s)

#1 Graduated end hinge

#1 Graduated end hinge

Dimples

#1Center

hinge(s)

#1 Graduated

end hinge

Lower

hinge leaf

1/4”-20 x 7/8”

Self drilling

screws

Short

stem

track

roller

Stru

t

1/4”-20 x 7/8”

Self drilling screws

Strut

clips

Stru

t

Lower

hinge

leaf

Strut

clip

Strut

#1 Graduated

end hinges

Long stem

track roller

End stile

End stile

#1Center

hinge(s)

#1 Graduated end hinges

#1 Graduated end hinges

1/4”-20 x 7/8”

Self drilling screws

Dimples

Lock or

Intermediate

section

Strut

#1Center

hinge(s)

Lower

hinge leaf

1/4”-20 x 7/8”

Self drilling

screws

Strut

clips

Stru

t

Strut

clips

Strut

Lower

hinge leafs

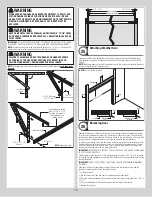

NOTE:

If a strut is required to be installed on a section with windows in it, half center hinge(s)

(if included) may need to be used instead of the typical center hinge(s).

Lower hinge leaf

1/4”-20 x 7/8”

Self drilling

screws

Strut

clips

Strut

Half center

hinge

Dimples

IMPORTANT:

ONCE THE 1/4” - 20 SELF DRILLING SCREWS ARE SNUG AGAINST THE

LOWER HINGE LEAFS, TIGHTEN AN ADDITIONAL 1/4 TO 1/2 TURN TO RECEIVE MAXIMUM

DESIGN HOLDING POWER.

Insert the appropriate stem track roller into the hinge tube of the graduated end hinges.

Repeat the same process for all remaining sections.

Short stem track roller

Long stem track roller

Single End Hinge

Double End Hinge

IMPORTANT:

WHEN PLACING STEM TRACK ROLLERS INTO THE #2 GRADUATED END HINGES

AND HIGHER, THE STEM TRACK ROLLER GOES INTO HINGE TUBE FURTHEST AWAY FROM

SECTION.

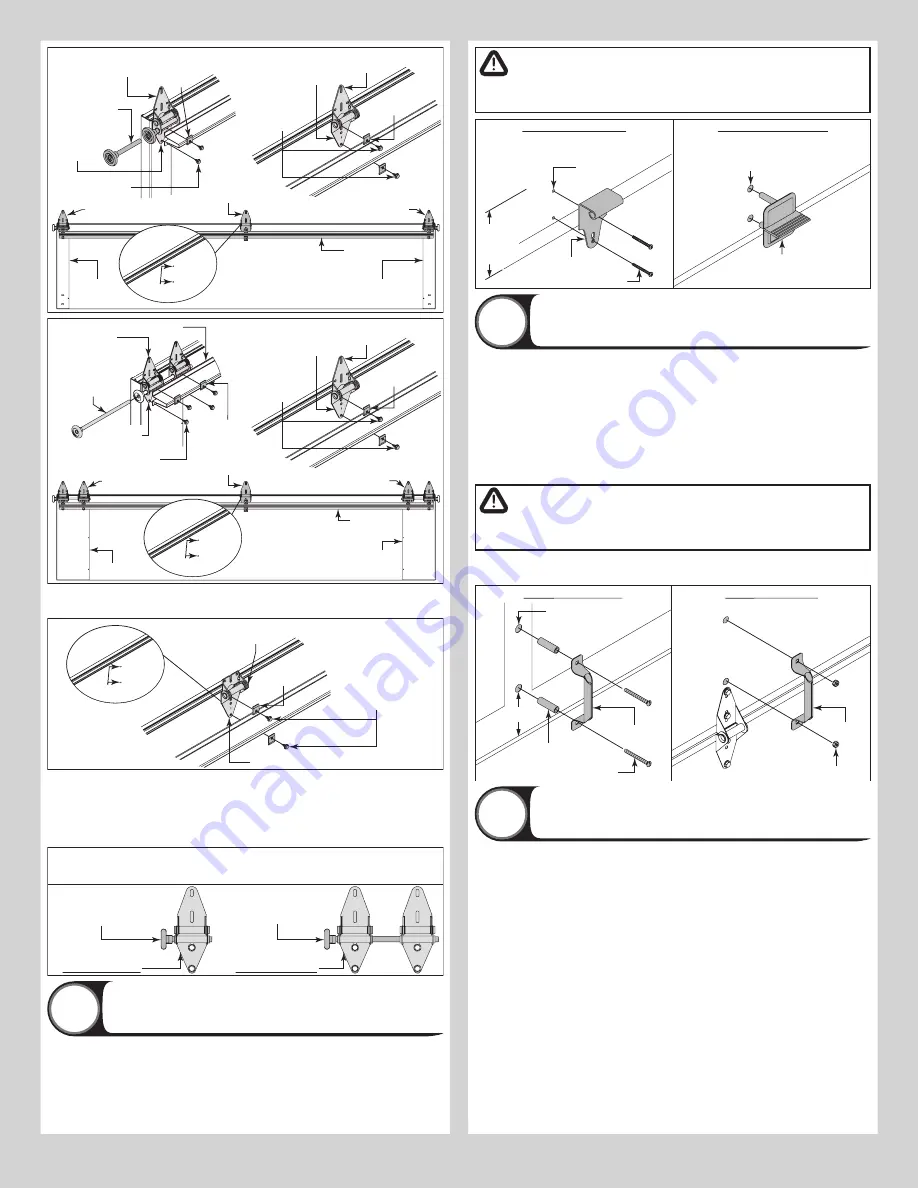

Step Plate

7

Locate the center most center stile on the bottom section of the door. On the inside of the

door and using the pre-punched holes at the bottom of the center stile as a template, drill (2)

7/32” dia. holes through the section. Using the previously drilled holes as a guide, enlarge

the holes from outside the door to 7/16” dia. and assemble the outside and inside step plates

to the section using (2) #8 x 1-5/8” screws.

CAUTION

DO NOT DRILL THROUGH OR ENLARGE HOLES ON THE INSIDE OF THE DOOR

SECTION.

Inside step plate

Bottom section inside

Pre-punched

holes

(2) #8 x 1-5/8” screws

8” Max.

mounting

height

Outside step plate

Bottom section outside

Holes enlarged

to 7/16” diameter

Lift Handle

8

NOTE:

Doors with a Keyed lock do not require this lift handle.

Locate the inside center stile or the desired lift handle location on the lock (2nd) section

of the door. Position the lower hole in the lift handle 4” from the bottom of the lock (2nd)

section.

IMPORTANT:

THE DISTANCE BETWEEN THE STEP PLATE AND THE MIDDLE OF THE LIFT

HANDLE MUST BE 20” MINIMUM TO 30” MAXIMUM. IF NECESSARY REPOSITION THE UPPER

LIFT HANDLE TO STAY WITHIN THE REQUIRED DIMENSION.

Using the lift handle holes as a template, drill (2) 9/32” dia. holes through the lock section.

Enlarge the holes from the outside the door to 1/2” dia.

CAUTION

DO NOT DRILL THROUGH OR ENLARGE HOLES ON THE INSIDE OF THE DOOR

SECTION.

Assemble the outside and inside lift handles to the lock section using (2) spacers, (2) 1/4” -

20 x 2-1/2” carriage bolts and (2) 1/4” - 20 hex nuts.

(2) Spacers

1/2” Diameter holes

(2) 1/4” x 2-1/2” Carriage bolts

Lift handle

4”

Lift handle

(2) 1/4”-20 hex nuts

Lock section outside

Lock section inside

Positioning Bottom Section

9

Center the bottom section in the door opening. Level the section using wooden shims (if

necessary) under the bottom section. When the bottom section is leveled, temporarily hold it

in place by driving a nail into the jamb and bending it over the edge of the bottom section on

both sides.

11

Summary of Contents for 8300

Page 25: ......