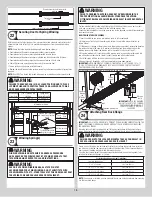

(3) 1/4”- 20 x 7/8”

Self-drilling screws

Pin

stripes

Top section

Strut

Drawbar

operator

bracket

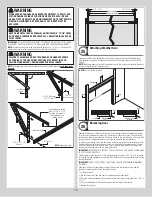

Attaching Horizontal Tracks

14

NOTE:

Depending on your door, you may have Fully Adjustable Flag Angles or you may have

Angle Mount Vertical Track Assemblies. Refer to Package Contents / Breakdown of Parts, to

determine which Flag Angles / Vertical Track Assemblies you have.

WARNING

DO NOT RAISE DOOR UNTIL HORIZONTAL TRACKS ARE SECURED AT

REAR, AS OUTLINED IN STEP, REAR BACK HANGS, OR DOOR COULD FALL

FROM OVERHEAD POSITION CAUSING SEVERE OR FATAL INJURY.

IF YOU HAVE FLAG ANGLES:

To install horizontal track, place the curved end over the top

track roller of the top section. Align the bottom of the horizontal track with the top of the verti-

cal track. Tighten the horizontal track to the flag angle with (2) 1/4” - 20 x 5/8” carriage bolts

and (2) 1/4” - 20 flange hex nuts.

3/8”-16

Hex nut

Horizontal

track angle

3/8”-16 x

3/4” Hex head

bolt

1/4”-20 x 5/8”

Carriage bolts

1/4”-20

Flange hex

nuts

Horizontal

track

Flag angle

upper slot

Level

IF YOU HAVE ANGLE MOUNT:

To install horizontal track, place the curved end over the top

track roller of the top section. Align the bottom of the horizontal track with the top of the verti-

cal track. Tighten the horizontal track to the angle mount with (2) 1/4” - 20 x 5/8” carriage

bolts and (2) 1/4” - 20 flange hex nuts.

3/8”-16

Hex nut

Angle

mount

3/8”-16 x 3/4”

Hex head bolt

1/4”-20 Flange

hex nuts

Horizontal

track

Upper slot

Level

Vertical

track

Horizontal

track angle

1/4”-20 x 5/8”

Carriage bolts

Next level the horizontal track assembly and bolt the horizontal track angle to the first

encountered slot in the flag angle / angle mount using (1) 3/8” - 16 x 3/4” hex head bolt and

(1) 3/8” - 16 hex nut. Repeat for other side. Remove nail that was temporally holding the top

section in position.

IMPORTANT:

FAILURE TO REMOVE NAIL BEFORE ATTEMPTING TO RAISE DOOR COULD

CAUSE PERMANENT DAMAGE TO TOP SECTION.

Level

Level

Horizontal

track angle

Horizontal

track

Horizontal

track angle

Horizontal

track

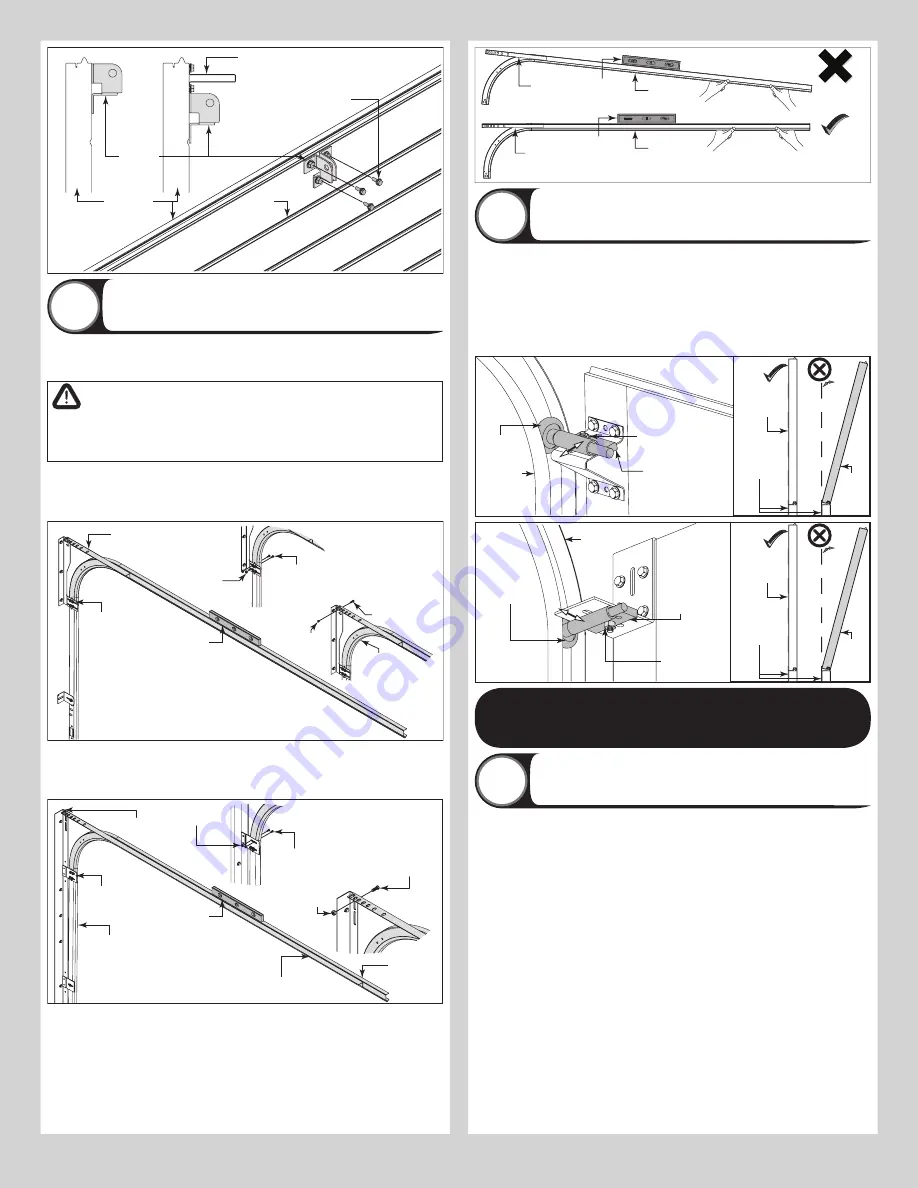

Adjusting Top Fixtures

15

NOTE:

Depending on your door, you may have Top Fixture Bases and Top Fixture Slides or

you may have Top Fixture Assemblies. Refer to Package Contents / Breakdown of Parts, to

determine which Top Fixtures you have.

With horizontal tracks installed, you can now adjust the top fixtures. Vertically align the top

section of the door with the lower sections. Once aligned, position the top fixture slide, out

against the horizontal track. Maintaining the slide’s position, tighten the 1/4” - 20 flange

hex nuts or the (1) 5/16” - 18 hex nut to secure the top fixture slide to the top fixture base.

Repeat for other side.

Top fixture slide

Tighten the

1/4”- 20 flange

hex nut

Horizontal

track

Track roller

Top section

Intermediate

section

Top

section

Top

section

Top fixture

slide

Horizontal

track

Track roller

Top

section

Intermediate

section

Top

section

Top

section

Tighten the

5/16”-18

hex nut

COUNTERBALANCE

INSTALLATION INSTRUCTIONS

Attaching Head Plates

16

NOTE:

Refer to Package Contents / Breakdown of Parts, to determine which head plates you

have.

NOTE:

Prior to fastening head plates into the door jamb, pilot drill using a 3/16” drill bit.

IMPORTANT:

RIGHT AND LEFT HAND IS ALWAYS DETERMINED FROM INSIDE THE BUILDING

LOOKING OUT.

NOTE:

Head plates are right and left hand.

Attach the left hand head plate to the left hand horizontal track angle using (2) 3/8” - 16

x 3/4” hex head bolts and (2) 3/8” - 16 nuts. Secure the top of the head plate to the jamb

using 5/16” x 2” lag screw(s). Repeat the same process for right hand side.

14

Summary of Contents for 8300

Page 25: ......