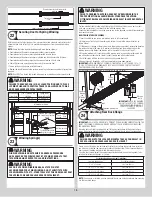

WARNING

MAKE SURE BACK HANGS ARE BRACED SUFFICIENTLY TO RESIST ANY

MOTION DURING SPRING APPLICATION AND DOOR TRAVEL. IF BACK

HANGS PIVOT OR DEFLECT, ADD REINFORCEMENT UNTIL THEY REMAIN

FIRM AND STATIONARY. ANY BACK HANG THAT IS BENT MUST BE

REPLACED.

WARNING

KEEP HORIZONTAL TRACKS PARALLEL AND WITHIN 3/4” TO 7/8” FROM

DOOR EDGE, OTHERWISE DOOR COULD FALL, RESULTING IN SEVERE OR

FATAL INJURY.

IMPORTANT:

DO NOT SUPPORT THE WEIGHT OF THE DOOR ON ANY PART OF THE REAR

BACK HANGS THAT CANTILEVERS 4” OR MORE BEYOND A SOUND FRAMING MEMBER.

NOTE:

If rear back hangs are to be installed over drywall, use (2) 5/16” x 2” hex head lag

screws and make sure lag screws engage into solid structural lumber.

WARNING

FAILURE TO ASSEMBLE AND ATTACH REAR BACK HANGS PROPERLY

ACCORDING TO THE ABOVE INSTRUCTIONS MAY RESULT IN DOOR

FALLING WHEN RAISED, CAUSING SEVERE OR FATAL INJURY.

NOTE:

Perforated angle must be attached to sound framing members and

nails should not

be used

.

90°

(3) 5/16”

Bolts and nuts

(3) 5/16” Bolts and

(3) 5/16” nuts

Perforated

angle

5/16” Hex nut

5/16”-18 x 1-1/4”

Hex bolt

Perforated angle bolted

using (2) 5/16” x 1-5/8”

hex head lag screws to

ceiling member and

parallel to door

Horizontal track

NOTE:

Repeat the same

process for right hand side.

Horizontal tracks

Door edges

3/4” To 7/8”

3/4” To 7/8”

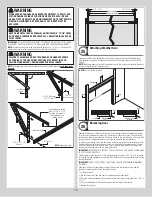

Attaching Weather Seal

25

Permanently attach the weatherstrips on both door jambs and header. The weatherstrips

were temporarily attached in Preparing the Opening, in the pre-installation section of this

manual.

NOTE:

When permanently attaching the weatherstrips to the jambs, avoid pushing the weath-

erstrips too tightly against the face of door.

Weather seal

s

Nail

Weather

seal

Jamb

Weather seal

installed

Jamb

Header

Jamb

Nail

NOTE:

Door not shown for clarity.

Balancing Door

26

Remove locking pliers. Lift door and check its balance. Adjustments to the required number

of spring turns stated may be necessary. If door rises off floor more than 2 ft. under spring

tension alone, reduce spring tension. If the door is hard to rise or drifts down on its own, add

spring tension. A poorly balanced door can cause garage door operator problems.

To adjust spring tension, fully close door. Apply locking pliers to track above third track roller.

Place locking pliers on torsion shaft, as shown in Step Attaching Counterbalance Lift Cables.

Insert a winding rod into the winding cone. Push upward on the winding rod slightly while

carefully loosening the set screws in the winding cone.

IMPORTANT:

BE PREPARED TO SUPPORT THE FULL FORCE OF THE TORSION SPRING ONCE

THE SET SCREWS ARE LOOSE.

Carefully adjust spring tension 1/4 turn. Retighten both set screws to 14-15 ft. lbs. of torque

in the winding cone and repeat for the other side. Recheck door balance and re-adjust spring

tension if needed.

IMPORTANT:

DO NOT ADJUST MORE THAN 1 TURN FROM THE RECOMMENDED NUMBER

OF TURNS.

If the door still does not operate easily, lower the door into the closed position, unwind

spring(s) completely, and recheck the following items:

1.) Is the door level?

2.) Are the torsion shaft and flag angles / angle mount level and plumb?

3.) Does the distance between the flag angles / angle mount equal door width plus 3-3/8” to

3-1/2”?

4.) Do the counterbalance lift cables have equal tension? Adjust if necessary.

5.) Rewind the spring(s).

19

Summary of Contents for 8300

Page 25: ......