DOOR INSTALLATION

INSTRUCTIONS

Before installing your door, be certain that you have read and followed all of the instruc-

tions covered in the pre-installation section of this manual. Failure to do so may result in an

improperly installed door.

NOTE:

Reference TDS 160 for general garage door terminology at

www.dasma.com

.

IMPORTANT:

IF THE DOOR WILL BE EXPOSED TO A SIGNIFICANT AMOUNT OF ROAD SALT,

PAINT THE BARE GALVANIZED BOTTOM WEATHER STEEL RETAINER TO INHIBIT RUSTING.

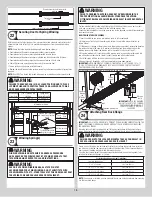

Preparing Vertical Tracks

1

NOTE:

If you have a wall angle track assembly, skip this step.

NOTE:

Refer to Door Section Identification / Breakdown Of Parts, to determine if you have

vertical tracks.

Vertical tracks may or may not have to be cut to the proper length, prior to installing.

IMPORTANT:

VERTICAL TRACKS ARE NOT REQUIRED TO BE CUT DOWN IF YOU HAVE DOOR

HEIGHTS 7’-0” OR 8’-0”.

Determine the radius of your horizontal track.

12”

Horizontal

track

Stamped

radius

Refer to the vertical track cutting chart to determine the length needed to be cut off at the top

of the vertical tracks. Using this measurement, measure and cut the vertical track off at the

top, as shown. Remove any burrs from the cut edge of vertical track.

Vertical Track Cutting Chart

Horizontal Track Radius

Vertical Track Cut Length

10” Or 12” Radius

Door Height Minus 10”

14” Radius

Door Height Minus 8”

Vertical

track

Top of

track

Measure and cut

Now, two holes must be drilled into the top of the cut vertical track. Using the illustration

shown below, mark and drill the hole locations using a 5/16” drill bit. Once the holes have

been drilled, remove any burrs from the drilled holes. Repeat the same process for the other

vertical track.

Vertical

track

Measure and drill

5/16” Holes

5/8”

5/8”

1/2”

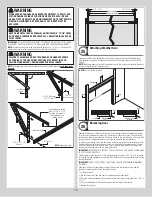

Attaching Flag Angles and Jamb Brackets To

Vertical Tracks

2

Hand tighten the left hand flag angle to the left hand vertical track using (2) 1/4” - 20 x 5/8”

carriage bolts and (2) 1/4” - 20 flange hex nuts.

NOTE:

The bottom jamb bracket is always the shortest bracket, while the center jamb

bracket is the next tallest. If three jamb brackets per side are included with your door, you will

have received a top jamb bracket, which is the tallest.

To attach the bottom jamb bracket, locate lower hole of the hole/ slot pattern of the 1st hole

set on the vertical track. Align the slot in the jamb bracket with the lower hole of the hole/ slot

pattern. Hand tighten jamb bracket using (1) 1/4” - 20 x 5/8” carriage bolt and (1) 1/4” - 20

flange hex nut.

Place the center jamb bracket over the lower hole of the hole/ slot pattern that is centered

between the bottom jamb bracket and flag angle of the 2nd hole set. Hand tighten jamb

bracket using (1) 1/4” - 20 x 5/8” carriage bolt and (1) 1/4” - 20 flange hex nut.

If a top jamb bracket was included, hand tighten it to vertical track using the lower hole of the

hole/ slot pattern in the 3rd hole set and (1) 1/4” - 20 x 5/8” carriage bolt and (1) 1/4” - 20

flange hex nut.

Left hand

vertical track

NOTE:

Loosely fasten components

together. Repeat the same

process for the right hand side.

Left hand

flag angle

Left hand

jamb bracket

Left hand

jamb bracket

3rd

Set

1st

Set

2nd

Set

1/4”-20 x 5/8”

Carriage bolts

1/4”-20 Flange

hex nuts

1/4”-20 x 5/8”

Carriage bolt

1/4”-20 Flange

hex nut

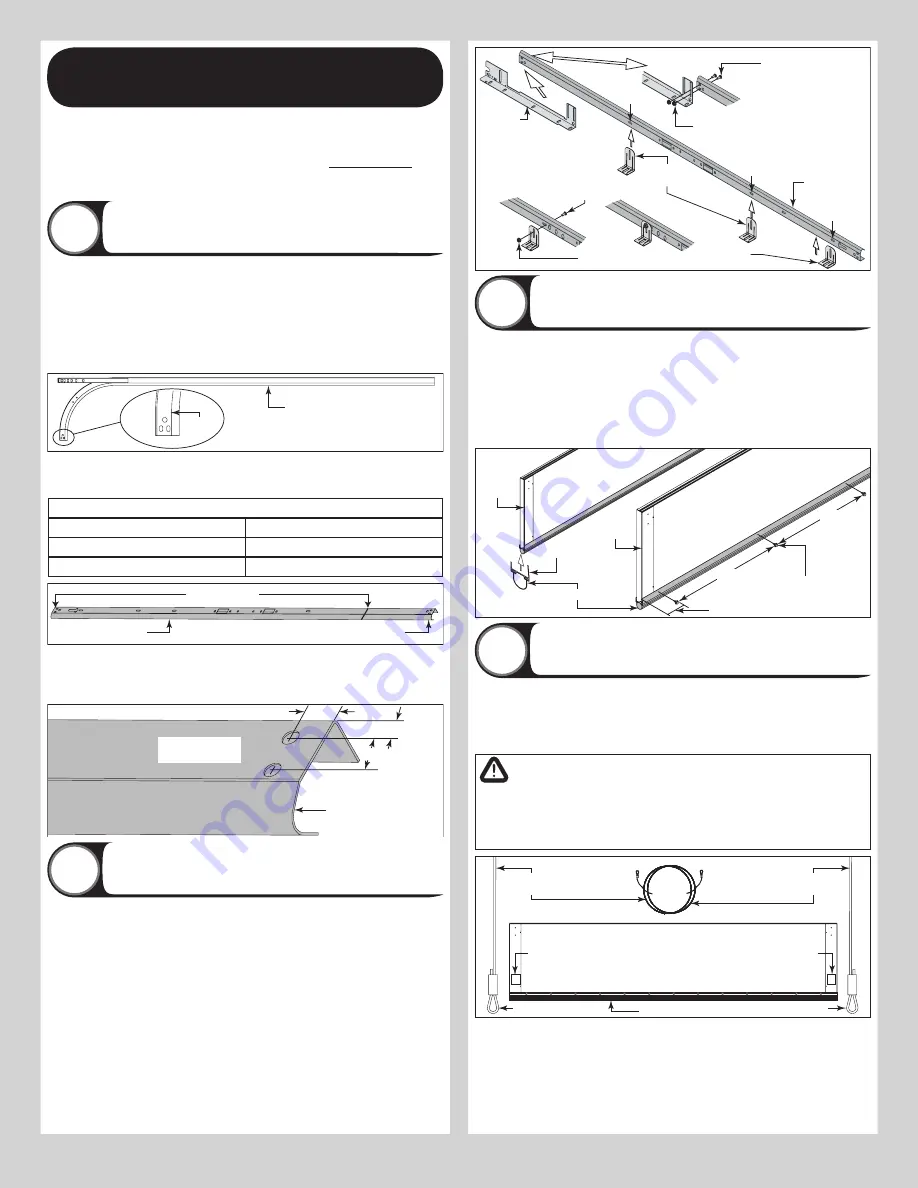

Bottom Weather Seal

3

NOTE:

Refer to door section identification, located in the pre-installation section of this

manual or refer to Breakdown Of Parts.

NOTE:

Verify that the bottom weather seal is aligned with bottom section. If needed, trim the

bottom weather seal even with bottom section length.

Position the bottom weather seal up against the bottom of the bottom section with the long

lip on the inside surface of the bottom section. From inside the door, attach the bottom

weather seal to the bottom section with 1/4” - 20 x 7/8” self drilling screws, placing one 6”

in from each end of the bottom section and one every 18” (maximum) in between, as shown.

Endcap

Bottom weather seal

1/4”-20 x 7/8” Self

drilling screws

Long lip

Inside

surface

of bottom

section

Inside surface of

bottom section

6”

18”

Endcap

18”

Attaching Bottom Corner Brackets

4

NOTE:

Refer to door section identification, located in the pre-installation section of this

manual or refer to Breakdown Of Parts.

Uncoil the counterbalance lift cables. Secure the cable loop to the clevis pin and bottom

corner bracket using a 5/16” flat washer and a cotter pin. Repeat for other bottom corner

bracket.

WARNING

ENSURE TIGHT FIT OF CABLE LOOP OVER PIN TO PREVENT

COUNTERBALANCE LIFT CABLE FROM COMING OFF THE PIN, WHICH

COULD ALLOW THE DOOR TO FALL AND RESULT IN SEVERE OR FATAL

INJURY.

Bottom weather seal

Cable loop

Bottom section

Cable loop

Bottom corner

bracket warning label

Bottom corner

bracket warning label

Counterbalance

lift cable

Counterbalance

lift cable

Position the left hand bottom corner bracket onto the bottom section. Attach the bottom

corner bracket to the bottom section with (3) 1/4” - 20 x 7/8” RED HEAD self drilling screws

and if applicable one more 1/4” - 20 x 7/8” self drilling screw. Repeat same process for the

right hand side.

IMPORTANT:

THE 1/4” - 20 X 7/8” RED HEAD SELF DRILLING SCREWS MUST BE MUST BE

INSTALLED THROUGH THE HOLES OF THE BOTTOM CORNER BRACKETS, AS SHOWN.

Insert a short stem track roller with a roller spacer (if applicable) into the bottom corner

7

Summary of Contents for 8300

Page 25: ......