bracket. Repeat for other side.

NOTE:

Verify bottom weather seal is aligned with bottom section. If there is more than 1/2”

excess weather seal on either side, trim weather seal even with bottom section.

End cap

(3) 1/4”-20 x 11/16” Self

drilling screws (RED HEAD )

Counterbalance cable loop

Cotter pin (attached into

place from opposite side

of bottom corner bracket)

Clevis pin (inserted through

cotter pin and bent into place)

Short stem

track roller

Bottom

corner bracket

Bottom

section

Bottom weather seal

End cap

1/4”-20 x 11/16”

Self drilling screw

Counterbalance

cable loop

Cotter pin (attached into

place from opposite side

of bottom corner bracket)

Clevis pin (inserted through

cotter pin and bent into place)

Short stem

track roller

Bottom

corner bracket

Bottom

section

Bottom weather

seal

(3) 1/4”-20 x 11/16” Self

drilling screws (RED HEAD )

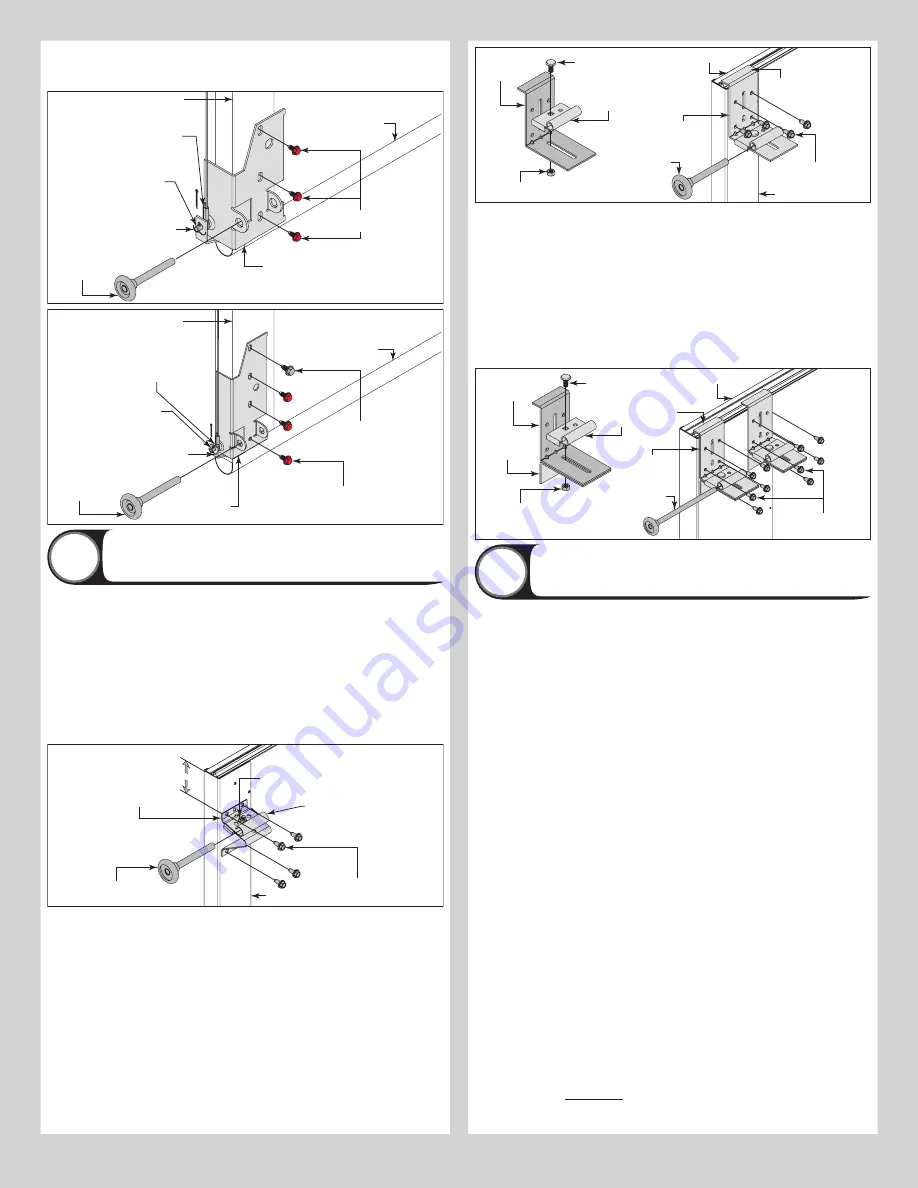

Attaching Top Fixtures To Top Section

5

NOTE:

Depending on your door, you may have Top Fixture Bases and Top Fixture Slides or

you may have Top Fixture Assemblies. Refer to Package Contents / Breakdown of Parts, to

determine which Top Fixtures you have.

IF YOU HAVE TOP FIXTURE ASSEMBLIES:

Starting on the left hand side, align the top

fixture base 3” down from the top section or below strut and even with the edge of the top

section. The slotted half of the top fixture base should be facing upwards. Fasten to section

through end cap using (4) 1/4” - 20 x 11/16” self drilling screws. Insert short stem track

roller into top fixture slide. Repeat for other side.

NOTE:

The top fixture slide will be tightened and adjusted later, in step, Adjusting Top Fixture.

NOTE:

Ensure the top fixture slide is able to slide along the top fixture base. If needed, loosen

the 1/4” - 20 flange hex nut.

(4) 1/4”-20 x 11/16”

Self drilling screws

Top fixture

base

End cap

Top fixture slide

Top section

1/4”-20

Flange hex nut

3”

Insert short

stem track roller

IF YOU HAVE 2 TOP FIXTURE BASES AND 2 TOP FIXTURE SLIDES:

Starting on the left

hand side of the top section, align the lip of the top fixture base onto the top corner of the top

section and even with the edge of the end cap. Fasten to section through end cap using (4)

1/4” - 20 x 11/16” self drilling screws. Loosely secure the top fixture slide to the top fixture

base using (1) 5/16” - 18 x 3/4” carriage bolt and (1) 5/16” - 18 hex nut. Insert short stem

track roller into top fixture slide. Repeat for other side.

NOTE:

The top fixture slide will be tightened and adjusted later, in step, Adjusting Top Fixture.

NOTE:

Ensure the top fixture slide is able to slide along the top fixture base. If needed, loosen

the 5/16” - 18 hex nut.

1/4”-20 x 11/16”

Self drilling screws

Top fixture

base

End cap

Insert short

stem track roller

Top section

Top fixture

base

5/16”-18 x 3/4”

Carriage bolt

5/16”-18 Hex nut

Top fixture

slide

Lip

IF YOU HAVE 4 TOP FIXTURE BASES AND 4 TOP FIXTURE SLIDES:

Starting on the left

hand side of the top section, align the lip of the top fixture base onto the top corner of the

top section and even with the edge of the end cap. Fasten to section through end cap using

(4) 1/4” - 20 x 11/16” self drilling screws. Loosely secure the top fixture slide and the “L”

reinforcement bracket to the top fixture base using (1) 5/16” - 18 x 3/4” carriage bolt and (1)

5/16” - 18 hex nut. Fasten the “L” reinforcement bracket to section through end cap using

(1) 1/4” - 20 x 11/16” self drilling screw. Repeat the same process for the other top fixture.

Insert long stem track roller into top fixture slides. Repeat for other side.

NOTE:

The top fixture slides will be tightened and adjusted later, in step, Adjusting Top

Fixture.

NOTE:

Ensure the top fixture slides are able to slide along the top fixture bases. If needed,

loosen the 5/16” - 18 hex nuts.

1/4”-20 x 11/16”

Self drilling screws

Top fixture

base

End cap

Insert long stem

track roller

Top section

Top fixture

base

5/16”-18 x 3/4”

Carriage bolt

5/16”-18 Hex nut

Top fixture

slide

Lip

“L” Reinforcing

bracket

Attaching Hinges and Struts

6

NOTE:

Refer to door section identification, located in the pre-installation section of this

manual to determine what size sections you need to use as your lock (second) section, inter-

mediate (third) section, intermediate (fourth) section, intermediate (fifth) section, intermediate

(sixth) section, intermediate (seventh) section, intermediate (eighth) section and top section.

Measure your sections to make sure they are the correct height as indicated on the chart.

FOR DOOR MODEL 8300:

The graduated end hinges can be identified by the number

stamped on the lower hinge leaf. The #2 graduated end hinges serves as end hinges on the

bottom section. The #1 graduated end hinges also serves as center hinges on all sections,

except for the top section.

The #3 graduated end hinges serves as end hinges on the Lock section.

The #4 graduated end hinges serves as end hinges on the Intermediate I section.

The #5 graduated end hinges serves as end hinges on the Intermediate II section.

The #6 graduated end hinges serves as end hinges on the Intermediate III section.

The #7 graduated end hinges serves as end hinges on the Intermediate IV section.

The #8 graduated end hinges serves as end hinges on the Intermediate V section.

The #9 graduated end hinges serves as end hinges on the Intermediate VI section.

FOR DOOR MODEL 8500:

The graduated end hinges can be identified by the number

stamped on the lower hinge leaf. The #1 graduated end hinges serves as end hinges on the

bottom section. The #1 graduated end hinges also serves as center hinges on all sections,

except for the top section.

The #2 graduated end hinges serves as end hinges on the Lock section.

The #3 graduated end hinges serves as end hinges on the Intermediate I section.

The #4 graduated end hinges serves as end hinges on the Intermediate II section.

The #5 graduated end hinges serves as end hinges on the Intermediate III section.

The #6 graduated end hinges serves as end hinges on the Intermediate IV section.

The #7 graduated end hinges serves as end hinges on the Intermediate V section.

The #8 graduated end hinges serves as end hinges on the Intermediate VI section.

NOTE:

Refer to the strutting schedules below to determine the placement of strut(s) on your

door. Be sure to use the proper schedules for the type of door model and the size of your

door.

IMPORTANT:

When referring to the strutting schedules, determine how many struts your

door needs and on what sections they are needed to be installed. Also use the correct strut-

ting schedule for the

proper color

of your door.

NOTE:

Sections not noted in the strutting schedule, do not require a strut. All strut(s) are

8

Summary of Contents for 8300

Page 25: ......