IF MOUNTING SURFACE IS A 2” X 6” BOARD INSTALLED ON TOP OF MASONRY, DRILL A

CLEARANCE HOLE IN MASONRY FOR THE 5/16” X 2-1/2” RED HEAD LAG SCREWS.

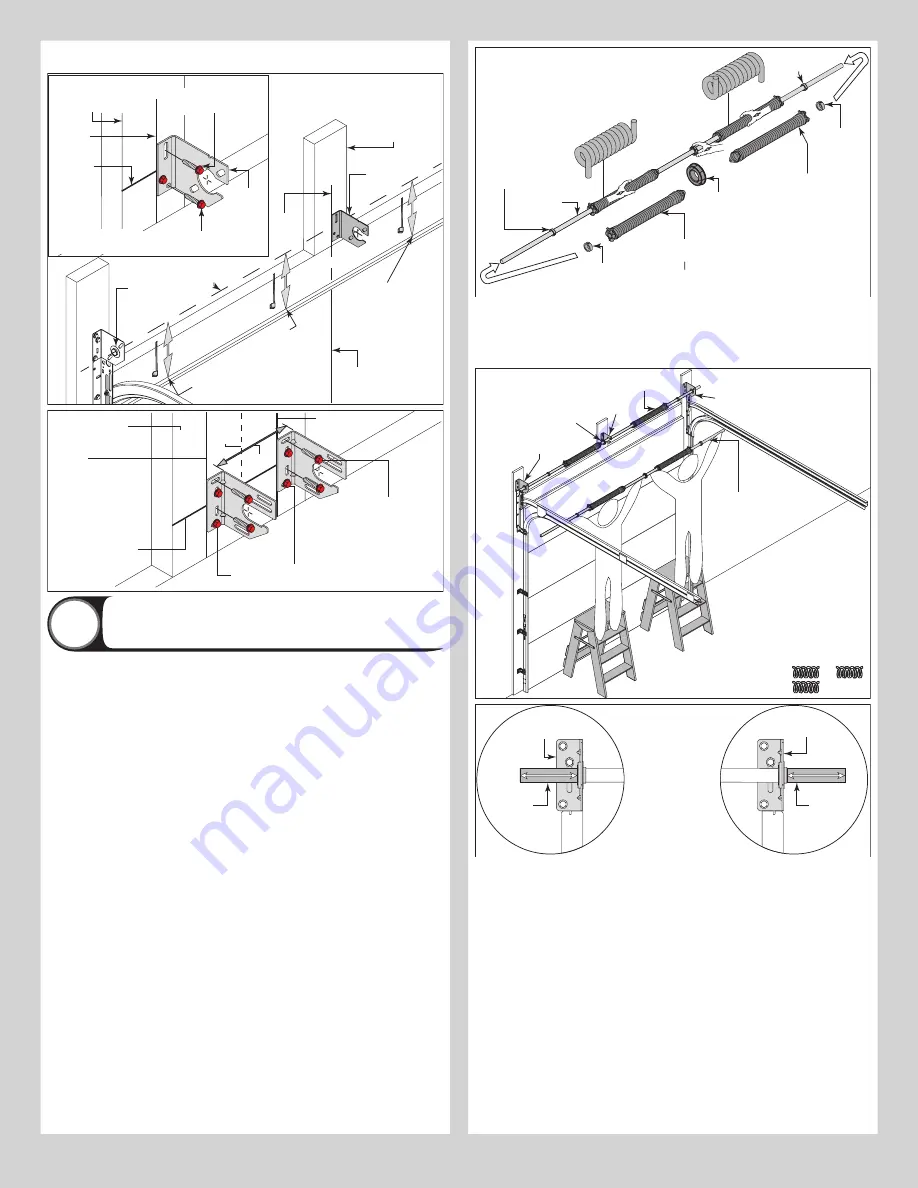

Spring mounting

pad (2” X 6”), White

Pine or denser.

Typical

center

bracket

Vertical

line

Equal distance (top of door

section to horizontal line)

Horizontal

line

Typical center

of left hand

end bearing

bracket

Jamb

Equal distance (top of door

section to horizontal line)

Center

of door

Center

bracket

5/16” x 1-5/8” Hex head

lag screws (RED HEAD)

Vertical

line

Horizontal

line

5/16” x 1-5/8” Hex head lag screw (RED HEAD) or

5/16” x 2-1/2” Hex head lag screw (RED HEAD)

Spring mounting

pad (2” X 6”), White

Pine or denser.

5/16” x 1-5/8” Hex head

lag screws (RED HEAD)

Vertical

line

Mounting surface

(17” Minimum)

Horizontal

line

Vertical line

† (2) Center bearing

brackets spaced 6” to

7” apart from the

center of the door.

Center

of

door

†12”

5/16” x 1-5/8” Hex head lag screw (RED HEAD) or

5/16” x 2-1/2” Hex head lag screw (RED HEAD)

Torsion Spring Assembly

18

NOTE:

Refer to the Package Contents and or Parts Breakdown to determine if your door

came with a coupler assembly.

IMPORTANT:

RIGHT AND LEFT HAND IS ALWAYS DETERMINED FROM INSIDE THE BUILDING

LOOKING OUT.

IMPORTANT:

IDENTIFY THE TORSION SPRINGS PROVIDED AS EITHER RIGHT WOUND (RED

WINDING CONE), WHICH GOES ON THE RIGHT HAND SIDE OR LEFT WOUND (BLACK WIND-

ING CONE), WHICH GOES ON THE LEFT HAND SIDE.

IMPORTANT:

ON SINGLE SPRING APPLICATIONS, ONLY A LEFT WOUND (BLACK WINDING

CONE), WHICH GOES ON THE LEFT HAND SIDE IS REQUIRED.

NOTE:

The set screws used on all torsion winding cones and cable drums are colored red.

DO NOT identify right and left hand by the set screw color.

IF YOU DON’T HAVE A COUPLER ASSEMBLY:

Facing the inside of the door, lay the torsion

shaft on the floor. Lay the torsion spring with the red winding cone at the right end of the

torsion shaft. Lay the torsion spring with the black winding cone at the left end of the torsion

shaft. Slide the center bracket bearing onto the torsion shaft followed by the torsion springs

and set collars (if applicable).

IMPORTANT:

THE CENTER BRACKET BEARING / TORSION SPRING(S) AND THE SET COL-

LARS (IF APPLICABLE) MUST BE POSITIONED, AS SHOWN.

Torsion

shaft

Left wound, black winding

cone (left hand side)

Right wound, red

winding cone

(right hand side)

IMPORTANT:

ON SINGLE SPRING APPLICATIONS, ONLY

A LEFT WOUND (BLACK WINDING CONE), IS REQUIRED.

NOTE:

Layout counterbalance

parts in proper orientation, then

install onto torsion shaft, as shown.

Set collar (if

applicable)

Set collar (if

applicable)

Set collar (if

applicable)

Set collar (if

applicable)

Center

bearing

bracket

With assistance, pick up the torsion spring assembly and slide one end of the torsion shaft

/ torsion keyed shaft through one end bearing bracket. Lay the middle of the torsion shaft /

torsion keyed shaft into the center bracket. Slide the other end of the torsion shaft / torsion

keyed shaft into the other end bearing bracket. Position the torsion shaft / torsion keyed shaft

so that equal amounts of the shaft extend from each end bearing bracket.

Left

hand

end

bearing

bracket

Center

bracket

Torsion spring

assembly

Right hand end

bearing bracket

Torsion spring

assembly

Center

bearing

bracket

Or

Torsion

shaft

Right hand end

bearing bracket

NOTE:

Position the

torsion shaft so that

equal amounts of the

shaft extend from each

end bearing bracket.

Torsion

shaft

Left hand end

bearing bracket

IF YOU HAVE A COUPLER ASSEMBLY:

Disassemble the coupler assembly by removing the

(3) 3/8” - 16 x 1-3/4” hex head screws and the (3) 3/8” - 16 nylon hex lock nuts from the

coupler halves. Loosen the set screws. Set the components aside.

9

Summary of Contents for 8700

Page 17: ......