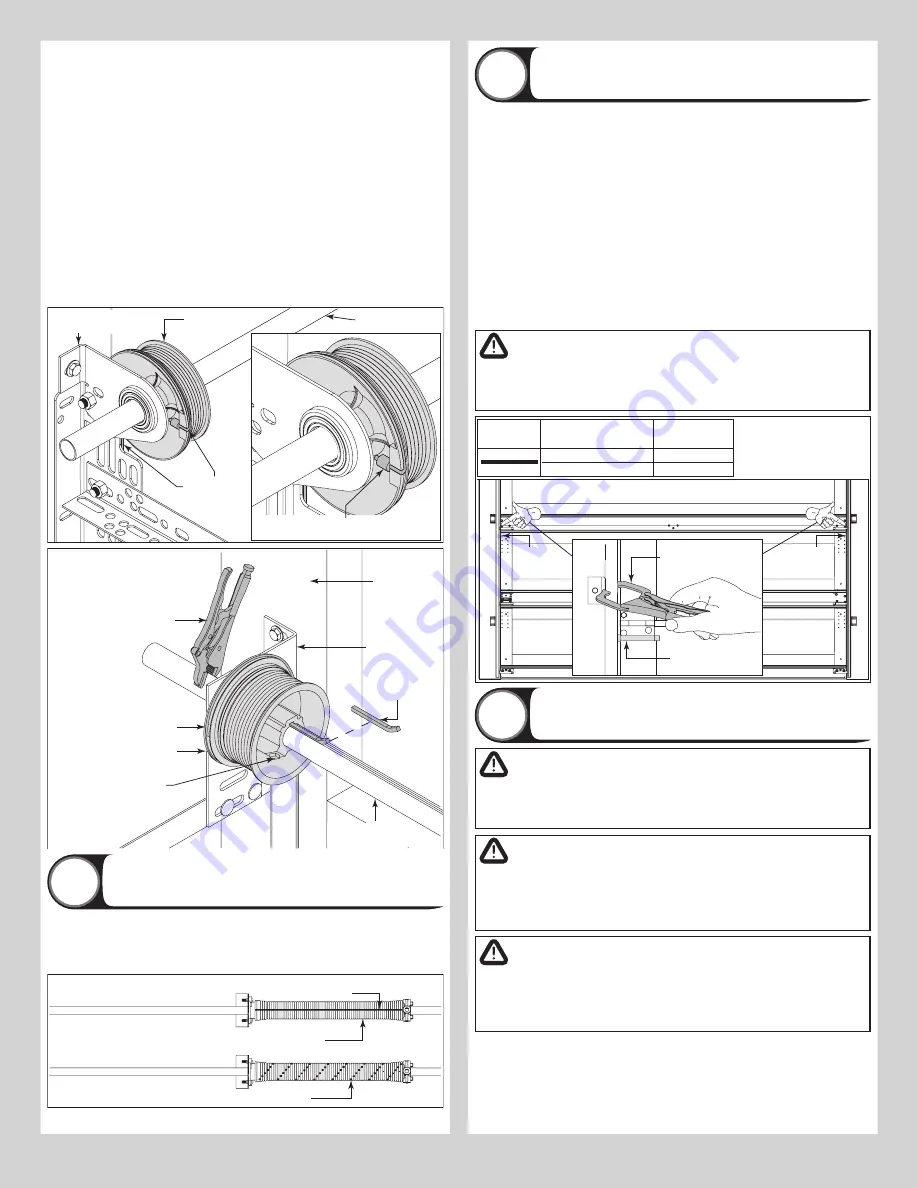

torque (once set screws contact the shaft, tighten screws one full turn).

NOTE:

If you have torsion keyed shaft(s), insert (1) key into the slot of both the cable drum

and the slot in the torsion keyed shaft, as shown.

Rotate the left hand drum and torsion shaft until counterbalance lift cable is taut. Now attach

locking pliers to the torsion shaft and brace locking pliers up against jamb to keep counter-

balance lift cable taut. Repeat for right hand side.

IMPORTANT:

INSPECT EACH COUNTERBALANCE LIFT CABLE MAKING SURE IT IS SEATED

PROPERLY ONTO THE CABLE DRUM AND THAT BOTH COUNTERBALANCE LIFT CABLES HAVE

EQUAL TENSION.

CHECK COUNTERBALANCE LIFT CABLES FOR EQUAL TENSION:

1. Attach locking pliers to track above top roller.

2. Grasp cable at approximate mid-door height location.

3. Draw cable toward you about 1/2” to 1” and release, noting the response of the cable.

4. Repeat above steps for other cable.

5. Adjust cable tension as needed until right and left cables both respond the same.

Once the counterbalance cables are set and if applicable tighten the coupler assembly

together by tightening the (3) 3/8” - 16 nylon hex nuts to secure the coupler halves together.

Counterbalance lift cable hooked in cable

drum

Counterbalance

lift cable

Typicall left hand

cable drum

Torsion shaft /

Torsion keyed shaft

Typicall left hand

end bearing bracket

Locking pliers

Set screws

Jamb

Key

Typicall left hand

cable drum

Torsion shaft /

Torsion keyed shaft(s)

Typicall left

hand end

bearing bracket

Counterbalance lift cable

hooked in cable drum

Chalking Torsion Spring(s)

19

NOTE:

If your springs have stenciling, then skip this step.

Draw a chalk line horizontally along the center of the torsion spring coil(s). As the torsion

spring is wound, the chalk line will create a spiral. This spiral can be used to count and

determine the number of turns that are applied on the torsion spring.

Draw horizontal chalk line prior to

winding

Spirals created after winding

Torsion spring

coils

Securing Door for Spring Winding

20

With the door in the fully closed position, place locking pliers onto both vertical tracks just

above the third track roller. This is to prevent the garage door from rising while winding

springs.

NOTE:

Check the following before attempting to wind torsion spring(s):

a. Counterbalance lift cables are secured at bottom corner brackets.

b. Counterbalance lift cables are routed unobstructed to cable drums.

c. Counterbalance lift cables are correctly installed and wound onto cable lift drums.

d. Counterbalance lift cables are taut and have equal tension on both sides.

e. Cable lift drums are against end bearing brackets and set screws are tight.

f. Torsion spring or springs are installed correctly.

g. Review the label attached to the spring warning tag, to determine number of spring turns

required.

NOTE:

Door MUST be closed and locked when winding or making any adjustments to the

torsion spring(s).

WARNING

FAILURE TO ENSURE DOOR IS IN A CLOSED POSITION AND TO PLACE

LOCKING PLIERS ONTO VERTICAL TRACK CAN ALLOW DOOR TO RISE

AND CAUSE SEVERE OR FATAL INJURY.

Winding Bars

(Steel Rods)

Size Of Winding Bar

(Inches)

Spring Inner

Diameter Used On

1/2” dia. x 18”

5/8” dia. x 24”

2” and 2-5/8”

3-3/4”

Locking pliers above

third track roller on

both sides of door

Bottom section

Lock

section

Locking pliers attached

to crown leg of vertical

track

Intermediate section

Vertical

track

Vertical

track

Winding Spring(s)

21

WARNING

WINDING SPRING IS AN EXTREMELY DANGEROUS PROCEDURE

AND SHOULD BE PERFORMED ONLY BY A TRAINED DOOR SYSTEM

TECHNICIAN USING PROPER TOOLS AND INSTRUCTIONS.

WARNING

USE ONLY SPECIFIED WINDING BARS, AS STATED IN STEP

SECURING DOOR FOR SPRING WINDING. DO NOT SUBSTITUTE WITH

SCREWDRIVERS, PIPE, ETC. OTHER TOOLS MAY FAIL OR RELEASE FROM

THE SPRING CONE AND CAUSE SEVERE OR FATAL INJURY.

WARNING

PRIOR TO WINDING THE SPRING, ENSURE YOU’RE WINDING IN THE

PROPER DIRECTION AS SHOWN BELOW. OTHERWISE THE SPRING

FITTING MAY RELEASE FROM SPRING AND RESULT IN SEVERE OR FATAL

INJURY.

Position a ladder slightly to the side of the spring so that the winding cone is easily acces-

sible, and so your body is not directly in line with the winding bars.

Check the label attached to the spring warning tag for the required number of complete turns

to balance your door.

HOW TO WIND TORSION SPRINGS:

1. Insert one winding rod snugly into winding cone, to full socket depth

15