Important Safety Instructions

DEFINITION OF KEY WORDS USED IN THIS MANUAL:

WARNING

INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH; IF NOT

AVOIDED, COULD RESULT IN SEVERE OR FATAL INJURY.

CAUTION

PROPERTY DAMAGE OR INJURY CAN RESULT FROM FAILURE TO FOLLOW

INSTRUCTIONS.

IMPORTANT:

REQUIRED STEP FOR SAFE AND PROPER DOOR OPERATION.

NOTE:

Information assuring proper installation of the door.

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING INSTALLATION. IF

IN QUESTION ABOUT ANY OF THE PROCEDURES, DO NOT PERFORM THE WORK.

INSTEAD, HAVE A TRAINED DOOR SYSTEMS TECHNICIAN DO THE INSTALLATION OR

REPAIRS.

1.

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2.

Wear protective gloves during installation to avoid possible cuts from sharp metal

edges.

3.

It is always recommended to wear eye protection when using tools, otherwise eye

injury could result.

4.

Avoid installing your new door on windy days. Door could fall during the installation

causing severe or fatal injury.

5.

Doors 12’-0” wide and over should be installed by two persons, to avoid possible

injury.

6.

Operate door only when it is properly adjusted and free from obstructions.

7.

If a door becomes hard to operate, inoperative or is damaged, immediately have

necessary adjustments and/ or repairs made by a trained door system technician using

proper tools and instructions.

8.

DO NOT stand or walk under a moving door, or permit anybody to stand or walk under

an electrically operated door.

9.

DO NOT place fingers or hands into open section joints when closing a door. Use lift

handles/ gripping points when operating door manually.

10.

DO NOT permit children to operate garage door or door controls. Severe or fatal injury

could result should the child become entrapped between the door and the floor.

11.

Due to constant extreme spring tension, do not attempt any adjustment, repair or

alteration to any part of the door, especially to springs, spring brackets, bottom corner

brackets, fasteners, counterbalance lift cables or supports. To avoid possible severe or

fatal injury, have any such work performed by a trained door systems technician using

proper tools and instructions.

12.

On electrically operated doors, pull down ropes must be removed and locks must be

removed or made inoperative in the open (unlocked) position.

13.

Top section of door may need to be reinforced when attaching an electric opener.

Check door and/ or opener manufacturer’s instructions.

14.

Visually inspect door and hardware monthly for worn and or broken parts. Check to

ensure door operates freely.

15.

Test electric opener’s safety features monthly, following opener manufacturer’s instruc-

tions.

16.

NEVER hang tools, bicycles, hoses, clothing or anything else from horizontal tracks.

Track systems are not intended or designed to support extra weight.

17.

This door may not meet the building code wind load requirements in your area. For

your safety, you will need to check with your local building official for wind load code

requirements and building permit information.

18.

For windloaded doors, the wind performance is achieved via the entire door system

and component substitution is not authorized without express permission by Wayne

Dalton.

NOTE:

It is recommended that 5/16” lag screws are pilot drilled using a 3/16” drill bit, prior

to fastening.

CAUTION

IF ANY PART OF THE DOOR IS TO BE INSTALLED ONTO PRESERVATIVE-

TREATED WOOD, PTFE-COATED OR STAINLESS STEEL FASTENERS MUST BE

OBTAINED AND USED. REPLACEMENT FASTENERS MUST BE OF AT LEAST

EQUAL STRENGTH AND SIZE AS ORIGINAL FASTENERS. IF THE ORIGINAL

FASTENER WAS RED-HEAD, THE REPLACEMENT FASTENER MUST BE RED-

HEAD ALSO. CONTACT WAYNE DALTON FOR FASTENER STRENGTH VALUES IF

NEEDED.

WARNING

IMPACT GUNS ARE NOT RECOMMENDED. WHEN INSTALLING 5/16” LAG

SCREWS USING AN ELECTRIC DRILL/ DRIVER, THE DRILL/ DRIVERS

CLUTCH MUST BE SET TO DELIVER NO MORE THAN 200 IN-LBS OF

TORQUE. FASTENER FAILURE COULD OCCUR AT HIGHER SETTINGS.

IMPORTANT:

RIGHT AND LEFT HAND IS DETERMINED INSIDE THE BUILDING LOOKING OUT.

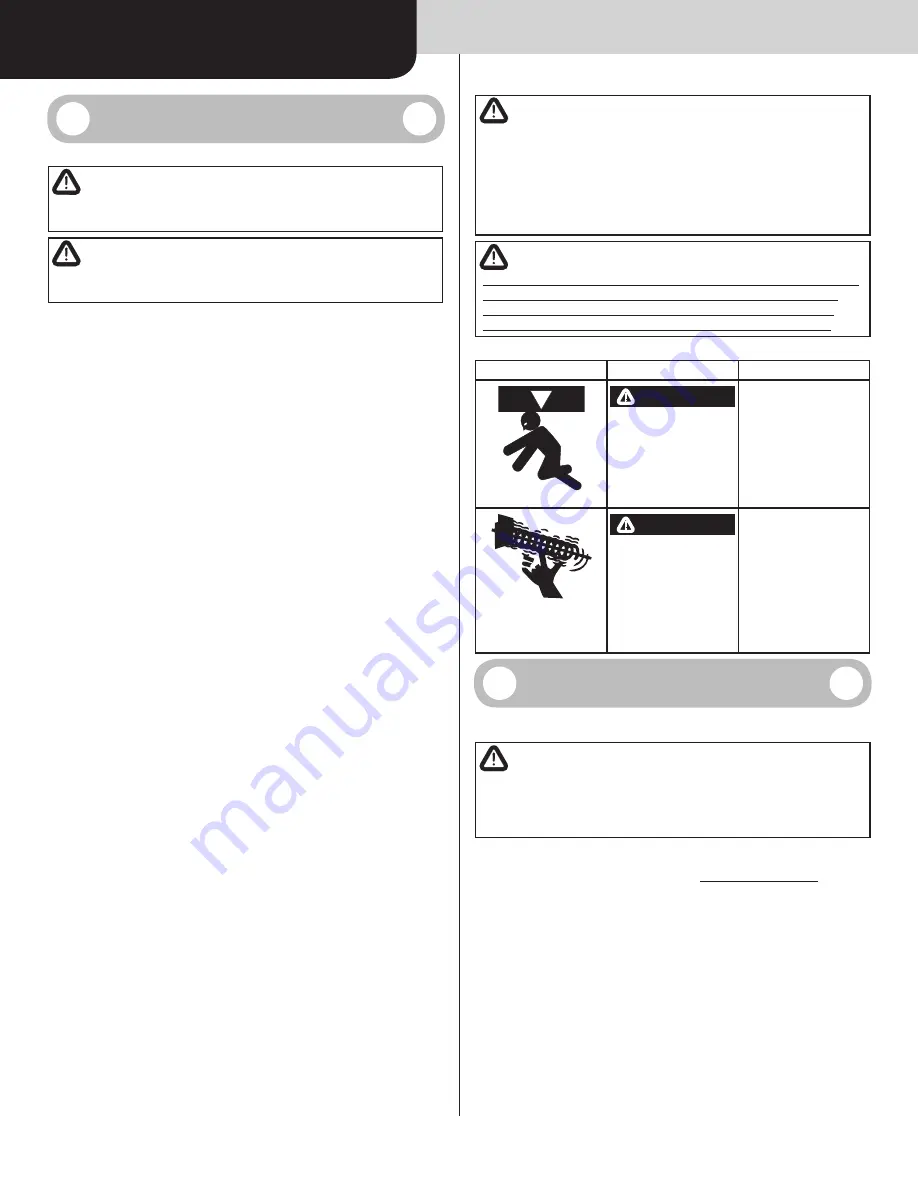

Potential Hazard

Effect

Prevention

Moving door

WARNING

Could result in Death or Serious

Injury

Keep people clear of opening

while Door is moving.

Do

NOT

allow children to play

with the Door Opener.

Do

NOT

operate a Door that

jams or one that has a broken

spring.

High tension spring

WARNING

Could result in Death or Serious

Injury

Do

NOT

try to remove, install,

repair or adjust springs or

anything to which door spring

parts are fastened, such as,

wood blocks, steel brackets,

cables or other like items.

Installations, repairs and

adjustments must be done by

a trained door system techni-

cian using proper tools and

instructions.

Removing an Existing Door

and Preparing the Opening

IMPORTANT:

COUNTERBALANCE SPRING TENSION MUST ALWAYS BE RELEASED BEFORE

ANY ATTEMPT IS MADE TO START REMOVING AN EXISTING DOOR.

WARNING

A POWERFUL SPRING RELEASING ITS ENERGY SUDDENLY CAN CAUSE

SEVERE OR FATAL INJURY. TO AVOID INJURY, HAVE A TRAINED DOOR

SYSTEMS TECHNICIAN, USING PROPER TOOLS AND INSTRUCTIONS,

RELEASE THE SPRING TENSION.

To avoid possible injury and to insure proper installation, it's highly recommended that you

read and fully understand the complete instructions on removing an Existing Door & Prepar-

ing the Opening. These are available for download at

www.Wayne-Dalton.com

or at your

local Wayne Dalton Sales Center.

IMPORTANT:

IF YOU JUST REMOVED YOUR EXISTING DOOR OR YOU ARE INSTALLING A

NEW DOOR, COMPLETE ALL STEPS IN PREPARING THE OPENING.

To ensure secure mounting of track brackets, side and center brackets, or steel angles to

new or retro-fit construction, it is recommended to follow the procedures outlined in DASMA

technical data sheets #156, #161 and #164 at

www.dasma.com

.

The inside perimeter of your garage door opening should be framed with wood jamb

and header material. The jambs and header must be securely fastened to sound framing

members. It is recommended that 2” x 6” lumber be used. The jambs must be plumb and

the header level. The jambs should extend a minimum of 12” (305 mm) above the top of

the opening for TorqueMaster

®

counterbalance systems. For low headroom applications, the

jambs should extend to the ceiling height. Minimum side clearance required, from the open-

ing to the wall, is 3-1/2” (89 mm).

IMPORTANT:

CLOSELY INSPECT JAMBS, HEADER AND MOUNTING SURFACE. ANY WOOD

FOUND NOT TO BE SOUND, MUST BE REPLACED.

For TorqueMaster

®

counterbalance systems, a suitable mounting surface (2” x 6”) must be

firmly attached to the wall, above the header at the center of the opening.

2

Pre-Installation