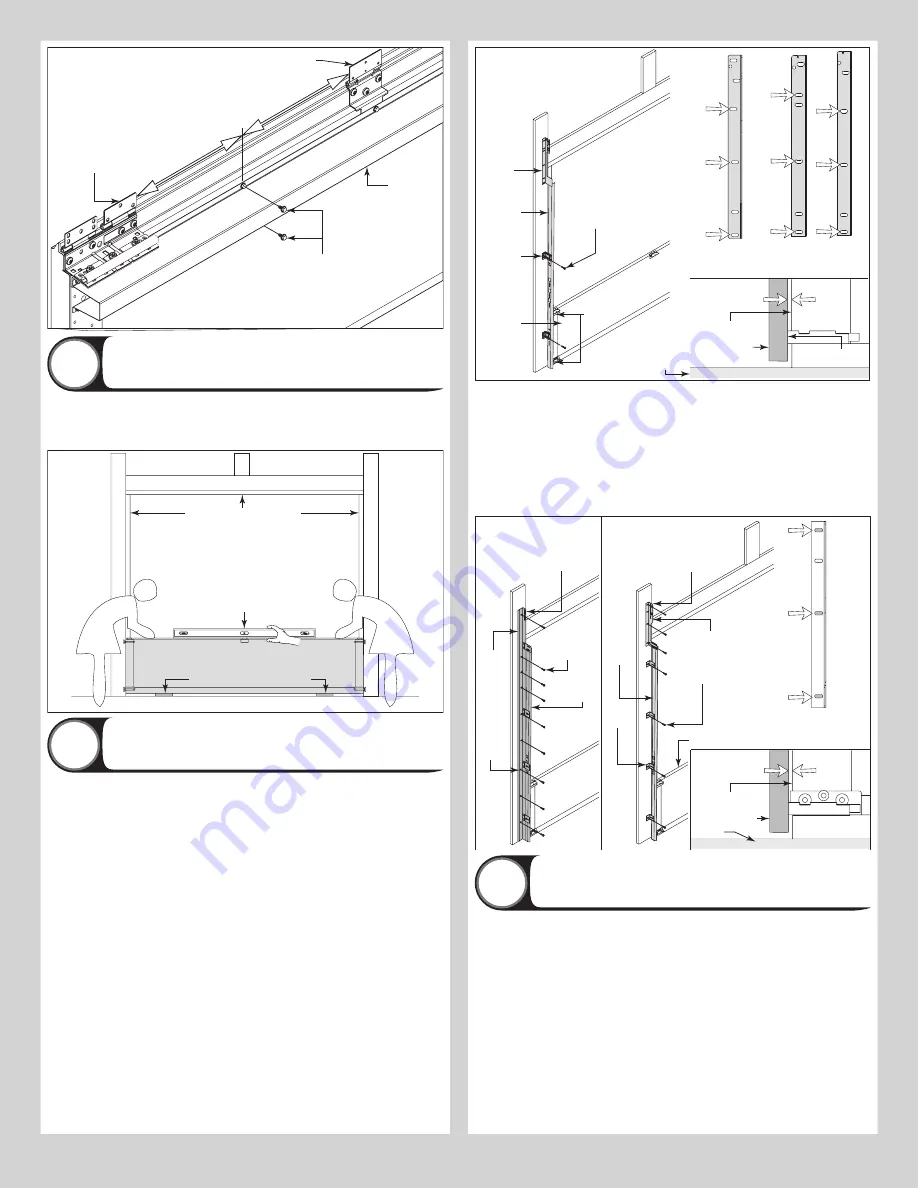

Typical

section

1/4”-20 x 7/8”

Self drilling screws

Graduated

end hinge

Typical

strut

Center

hinge(s)

=

=

NOTE:

Refer to the Windload Specification Sheet

to determine if more fasteners are required to

secure the strut to the section, as shown.

Positioning Bottom Section

6

Center the bottom section in the door opening. Level the section using wooden shims (if

necessary) under the bottom section. When the bottom section is leveled, temporarily hold it

in place by driving a nail into the jamb and bending it over the edge of the bottom section on

both sides.

Weather seal (If applicable)

Level

Bottom section

Wooden shims (If necessary)

Attaching Vertical Tracks To Jambs

7

NOTE:

Depending on your door, you may have Quick Install Flag Angles, Fully Adjustable Flag

Angles, Riveted Vertical Track Assemblies or you may have Angle Mount Vertical Track As-

semblies. Refer to Package Contents / Breakdown of Parts, to determine which Flag Angles /

Vertical Track Assemblies you have.

IMPORTANT:

IF YOUR DOOR IS TO BE INSTALLED PRIOR TO A FINISHING CONSTRUCTION

OF THE BUILDING’S FLOOR, THE VERTICAL TRACKS AND THE DOOR BOTTOM SECTION

ASSEMBLY SHOULD BE INSTALLED SUCH THAT WHEN THE FLOOR IS CONSTRUCTED, NO

DOOR OR TRACK PARTS ARE TRAPPED IN THE FLOOR CONSTRUCTION.

IMPORTANT:

THE TOPS OF THE VERTICAL TRACKS MUST BE LEVEL FROM SIDE TO SIDE.

IF THE BOTTOM SECTION WAS SHIMMED TO LEVEL IT, THE VERTICAL TRACK ON THE

SHIMMED SIDE MUST BE RAISED THE HEIGHT OF THE SHIM.

NOTE:

Make sure the counterbalance lift cable is located between the track rollers and the

door jamb.

Starting on the left hand side of the bottom section, remove the nail. Position the left hand

vertical track assembly over the track rollers of the bottom section and install, as shown. Drill

3/16” pilot holes into the door jamb for the lag screws.

FOR QUICK INSTALL FLAG ANGLES OR FULLY ADJUSTABLE FLAG ANGLES:

Loosely

fasten jamb brackets and flag angle to the jamb using 5/16” x 1-5/8” lag screws. Tighten lag

screws, securing the bottom jamb bracket to jamb, maintain 3/8” to 5/8” spacing, between

the bottom section and vertical track. Hang counterbalance lift cable over flag angle. Repeat

same process for other side.

Vertical

track

assembly

Jamb

bracket

Flag

angle

Flag angle lag screw locations

5/16” x 1-5/8”

Lag screws

Bottom

section

Track

rollers

3/8” to 5/8”

Spacing

Bottom section

15R QI

12R QI

Floor

Track roller

12R FA Or 15R FA

Vertical track

FOR RIVETED VERTICAL TRACK ASSEMBLY:

Loosely fasten jamb brackets and flag angle

to the jamb using 5/16” x 1-5/8” lag screws. Tighten lag screws, securing the bottom jamb

bracket to jamb, maintain 3/8” to 5/8” spacing as shown between the bottom section and

vertical track. Hang counterbalance lift cable over flag angle. Repeat same process for other

side.

FOR ANGLE MOUNT VERTICAL TRACK ASSEMBLY:

Loosely fasten the slots in the wall

angle to the jamb using 5/16” x 1-5/8” lag screws. Tighten lag screws, securing the bottom

slot in the wall angle, maintain 3/8” to 5/8” spacing as shown between the bottom section

and vertical track. Hang counterbalance lift cable over angle mount. Repeat same process for

other side.

Flag angle lag screw

locations

3/8” to 5/8”

Spacing

Bottom section

Vertical track

Bottom section

Vertical

track

Jamb

bracket

Flag

angle

5/16” x 1-5/8”

Lag screws

Floor

Angle mount

vertical track

assembly

Bottom

section

Riveted

vertical track

assembly

5/16” x 1-5/8”

Lag screws

Vertical

track

Wall

angle

Slot

Stacking Sections

8

NOTE:

The sections can be identified by the graduation of the factory installed end hinges.

The smallest graduated end hinge on section should be stacked on top of the bottom section,

with each graduated end hinge increasing as the sections are stacked, see Door Section

Identification.

NOTE:

Make sure graduated end and center hinges are flipped down, when stacking another

section on top.

Place track rollers into graduated end hinges of remaining sections.

With assistance, lift second section and guide the track rollers into the vertical tracks. Lower

section until it is seated against bottom section. Align vertical marks in the upper alignment

sticker, with the lower alignment sticker on right hand side, on the back of door. Keep sec-

tions aligned and fasten center hinge(s) first; then end hinges last using 1/4” - 14 x 5/8” self

tapping screws.

NOTE:

To prevent center hinge leaf(s) from rotating, first secure the top middle hole of the

center hinge leaf with one 1/4” - 14 x 5/8” self-tapping screw then secure the other two

holes.

9