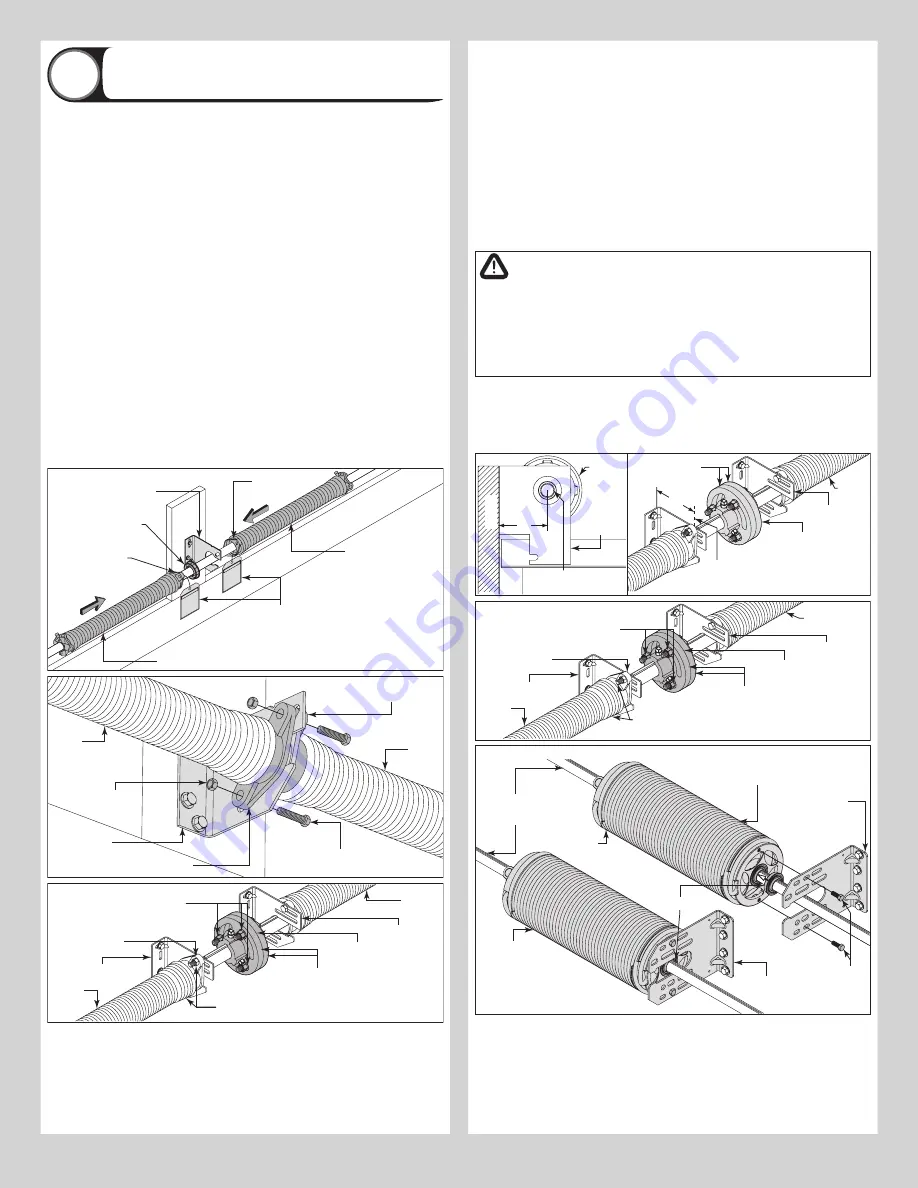

Attaching Springs to Center Bracket

23

NOTE:

Refer to Package Contents / Breakdown of Parts, to determine which Center

Bracket(s) came with your door.

NOTE:

Refer to Package Contents / Breakdown of Parts, to determine if your door came with

a coupler assembly.

IMPORTANT:

THE SPRING WARNING TAG(S) SUPPLIED MUST BE SECURELY ATTACHED

TO THE STATIONARY SPRING CONE(S) IN PLAIN VIEW. SHOULD A REPLACEMENT SPRING

WARNING TAG BE REQUIRED, CONTACT WAYNE DALTON FOR FREE REPLACEMENTS.

NOTE:

Measure the diameter of your springs. If your spring diameter is 3-3/4”, the springs

do not share center brackets. If your spring diameter is either 2” or 2-5/8”, then two springs

will share the same center bracket, unless a coupler assembly is provided.

IF YOU DON’T HAVE A COUPLER ASSEMBLY:

Slide center bracket bearing into the spring.

Align the stationary spring cone(s) with the holes in the center bracket. Secure the torsion

spring(s) to the center bracket with (2) 3/8” - 16 x 1-1/2” hex head bolts and (2) 3/8” - 16

nuts.

IMPORTANT:

NEVER USE MORE THAN ONE BEARING WHEN ATTACHING TWO SPRINGS TO

ONE CENTER BRACKET.

IF YOU HAVE A COUPLER ASSEMBLY:

Slide center bracket bearing into the spring. Align

the stationary spring cone with the holes in the center bracket. Secure the torsion spring to

the center bracket with (2) 3/8” - 16 x 1-1/2” hex head bolts and (2) 3/8” - 16 nuts. Repeat

the same process for the other center bearing bracket.

At the middle of the two center bearing brackets, re-assemble the coupler assembly by

loosely fastening the coupler halves together using the (3) 3/8” - 16 x 1-1/2” hex head

screws, (6) 3/8” washers, (3) 3/8” lock washers and the (3) 3/8” - 16 hex nuts, previously

removed.

NOTE:

Ensure both torsion keyed shafts have equal amounts of the shafts extending from

each end bearing bracket.

Typical center

bracket bearing

Stationary

spring cone

Typical center

bracket

Stationary

spring cone

Torsion spring

Spring

warning tags

Torsion spring

Typical center

bracket

Stationary spring cone

(2) 3/8”-16 x 1-1/2”

Hex head bolts

(2) 3/8”-16

Nuts

Torsion

spring

Torsion

spring

Stationary

spring cone

Coupler halves

Coupler

assembly

(3) 3/8” - 16 x 1-3/4”

hex head screws and

(3) 3/8” - 16 Hex nuts

Stationary

spring cone

Torsion

spring

(2) 3/8”-16 x 1-1/2” Hex head

bolts and (2) 3/8”-16 Hex nuts

Torsion

spring

Center bracket

Center

bracket

NOTE:

Refer to Package Contents / Breakdown of Parts, to determine which Center

Bracket(s) came with your door.

NOTE:

Refer to Package Contents / Breakdown of Parts, to determine if your door came with

a coupler assembly.

IMPORTANT:

THE SPRING WARNING TAG(S) SUPPLIED MUST BE SECURELY ATTACHED

TO THE STATIONARY SPRING CONE(S) IN PLAIN VIEW. SHOULD A REPLACEMENT SPRING

WARNING TAG BE REQUIRED, CONTACT WAYNE DALTON FOR FREE REPLACEMENTS.

FOR SPRINGS UP TO 3-3/4” ID AND IF YOU DON’T HAVE A COUPLER ASSEMBLY:

Slide

center bearing into the spring (if applicable). Align the stationary spring cone(s) with the holes

in the center bracket assembly. Secure the torsion spring(s) to the center bracket assembly

with (2) 3/8” - 16 x 1-1/2” hex head bolts and (2) 3/8” - 16 nuts.

IF YOU HAVE A COUPLER ASSEMBLY:

Slide the center bearing into the spring. Align the

stationary spring cone with the holes in the center bearing bracket.

NOTE:

Prior to attaching the torsion spring(s) to the center bracket(s), the torsion shaft /

torsion keyed shafts have to be at the same elevation as the bearing in the end bearing

brackets. Slide the torsion shaft / torsion keyed shafts out to the correct shaft centerline from

the jambs before tightening the spring assembly fasteners.

FOR SPRINGS UP TO 3-3/4” ID:

Secure the torsion spring to the center bracket with (2)

3/8” - 16 x 1-1/2” hex head bolts and (2) 3/8” - 16 nuts. Repeat the same process for the

other center bearing bracket.

FOR 6” AND DUPLEX SPRINGS:

Secure the torsion spring and the flange bearing to the

center bracket using (2) 3/8” - 16 x 1” Hex head bolts, as shown.

WARNING

FOR DUPLEX SPRINGS, YOU MUST ENSURE THE ASSEMBLY BOLTS

GO THROUGH THE CENTER BRACKET AND INNER SPRING CONE AND

THREAD INTO THE OUTER SPRING CONE AS SHOWN. FAILURE TO

ENSURE THE BOLTS ARE SECURING BOTH THE INNER AND OUTER

SPRING CONES TO THE CENTER BRACKET CAN RESULT IN SUDDEN

SPRING TENSION RELEASE, CAUSING SEVERE OR FATAL INJURY.

At the middle of the two center bearing brackets, loosely re-assemble the coupler assembly

by fastening the coupler halves together using the (3) 3/8” - 16 x 1-3/4” hex head screws

and the (3) 3/8” - 16 nylon hex lock nuts, as shown.

NOTE:

Ensure both torsion keyed shafts have equal amounts of the shafts extending from

each end bearing brackets.

Coupler

halves

Coupler

assembly

End bearing

bracket

Torsion shaft or

Torsion keyed shafts

Torsion

spring

Cable

drum

Center

bracket

=

Surface

=

Torsion shaft(s)

centerline

Coupler halves

Coupler

assembly

(3) 3/8” - 16 x 1-3/4” hex head

screws and (3) 3/8” - 16 Hex nuts

Stationary

spring cone

Torsion

spring

(2) 3/8”-16 x 1-1/2”

Hex head bolts and (2)

3/8”-16 Hex nuts

Torsion

spring

Center bracket

Center

bracket

Up To 3-3/4” Springs Applications

Torsion shaft /

Torsion keyed

shaft(s)

3/8” - 16 x 1”

Hex head

screws

Outer torsion

spring assembly

Center bracket

Outer torsion

spring assembly

Flange bearing

Center bracket

6” ID Springs

NOTE:

This type of torsion spring

assembly has just an outer spring,

no inner spring assembly.

6” Springs Applications

10