anchors (by others). This installation will require the 1/2” anchors to be secured to the build-

ing and then secure the brackets to the anchors, as shown.

NOTE:

Pre-Drill 1/2” pilot holes into the pre-cast for the 1/2” x 3” sleeve anchors.

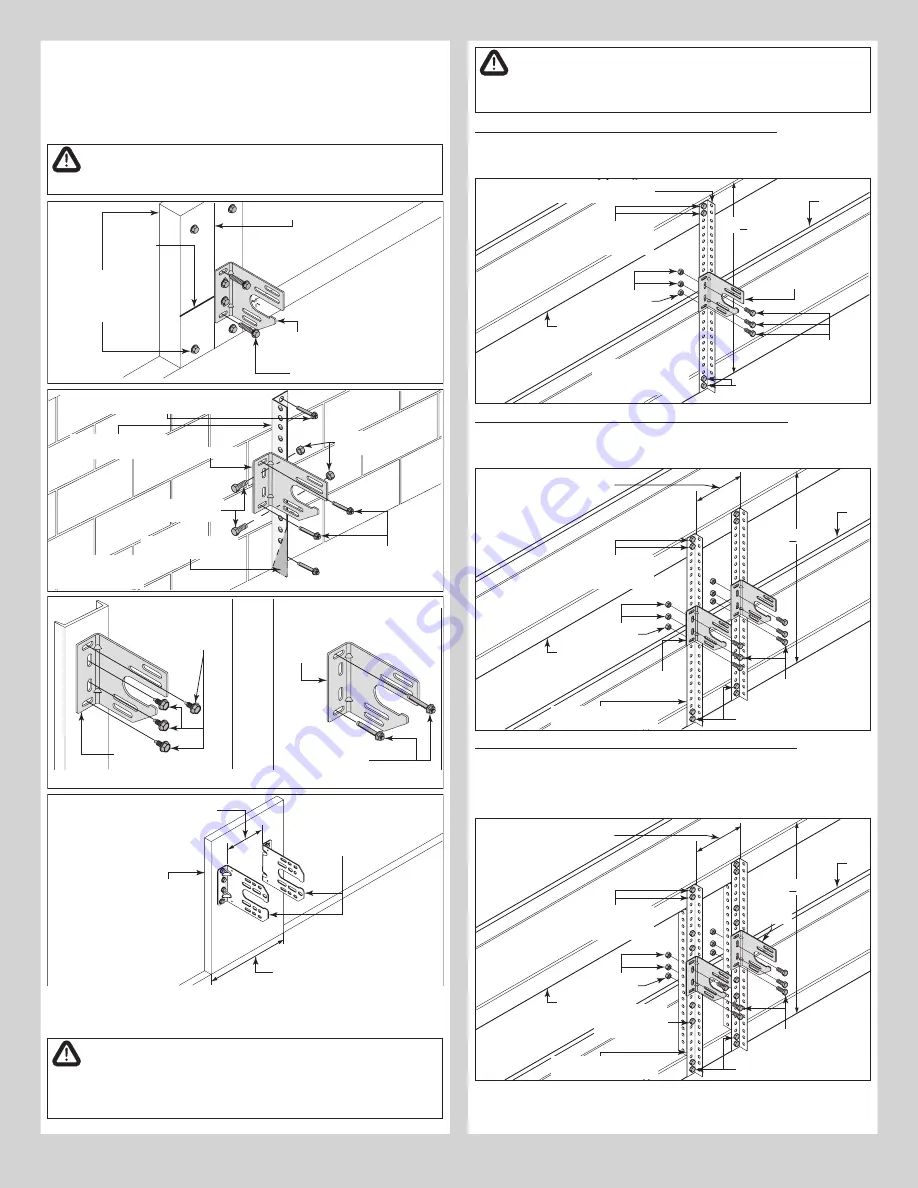

FOR BLOCK CONSTRUCTION:

Attach perforated angle 18” long to center bracket(s) using

(2) 3/8” x 1-1/4” bolts and (2) 3/8”nuts. Chamfer angle to clear top section high arc. Secure

center bracket(s) and perforated angle to block using (4) 3/8” x 2-1/2” sleeve anchors, as

shown.

WARNING

DO NOT USE SLEEVE ANCHORS ON HOLLOW BLOCK.

Vertical line

Spring mounting pad (2”

X 6“) White Pine or

denser. Secured with a

minimum of (4) 5/16” x

4” lag bolts into header.

Horizontal

line

Center

bracket

5/16” x 1-5/8” Hex

head lag screws

Wood

NOTE:

Actual center bracket may

vary, see breakdown of parts.

(2) 3/8” x 1-1/4”

Hex bolts

Center bracket

(2) 3/8”

Hex nuts

Chamfered to clear

door high-arc.

Sleeve anchors (3/8” x

2-1/2”) positioned in

the top and bottom slot

of center bracket.

(18” length) Perforated

angle

Concrete

Blocks

NOTE:

All (4) sleeve anchors (3/8” x 2-1/2”) must

be positioned a minimum of 1” from block edge.

NOTE:

Actual center

bracket may vary, see

breakdown of parts.

Center

bracket

(Steel Jambs) (4) 5/16” x 1”

Self drilling screws

Steel

Pre-Cast

Center

bracket

(Pre-cast) (2) 1/2” x 4”

Sleeve anchors

NOTE:

Must secure

sleeve anchors first, then

attach center brackets to

sleeve anchors.

NOTE:

Actual center bracket may vary, see breakdown of parts.

12”

Center

brackets

Mounting

surface

17”

Minimum

NOTE:

Actual center bracket may

vary, see breakdown of parts.

FOR ALTERNATE STEEL SPRING PAD APPLICATIONS:

IMPORTANT:

DO NOT BOLT TWO 3-3/4” OR LARGER DIAMETER SPRINGS TO ONE CENTER

BRACKET.

WARNING

THESE SPRING MOUNTING TECHNIQUES ARE NOT SUPPORTED FOR 800-

32 CABLE DRUMS. THESE INSTRUCTIONS ARE ALSO NOT APPLICABLE

FOR 5750-120 CABLE DRUMS WITH 72” OR MORE HIGH-LIFT.

WARNING

MAXIMUM SPACING FOR DIMENSION “Y” IS 84” (7 FT.) THESE

INSTRUCTIONS ARE NOT APPLICABLE FOR A SPAN GREATER THAN 84”..

Maximum Door Size 9’0” x 9’0” (Maximum Door Weight 210 lb.)

Cut perforated angle (1-5/8” x 2-3/8” x 11 GA.) to Dim “Y”. Thru-bolt top and bottom of

angle to each girt using (4) 3/8” x 1-1/4” bolts and (4) 3/8”nuts. Thru-bolt center bracket to

perforated angle using (3) 3/8” x 1-1/4” bolts and (3) 3/8” nuts, as shown.

(3) 3/8” x 1-1/4”

Hex bolts

Center bracket

(3) 3/8”

Hex nuts

Heavy perforated angle

(1-5/8” x 2-3/8” x 11ga.)

Girt

Girt

(2) 3/8” x 1-1/4”

Hex bolts and (2)

3/8” Hex nuts

“Y” (< 7 FT.)

(2) 3/8” x 1-1/4”

Hex bolts and (2) 3/8” Hex nuts

NOTE:

Actual center

bracket may vary, see

parts breakdown.

Maximum Door Size 14’0” x 12’0” (Maximum Door Weight 400 lb.)

Cut (2) perforated angle (1-5/8” x 2-3/8” x 11 GA.) to Dim “Y”. Thru-bolt top and bottom of

each angle to each girt using (4) 3/8” x 1-1/4” bolts and (4) 3/8” nuts. Thru-bolt each center

bracket to perforated angle using (3) 3/8” x 1-1/4” bolts and (3) 3/8” nuts, as shown.

(3) 3/8” x 1-1/4”

Hex bolts

Center

brackets

(3) 3/8”

Hex nuts

Heavy perforated angles

(1-5/8” x 2-3/8” x 11ga.)

Girt

Girt

(2) 3/8” x 1-1/4”

Hex bolts and (2)

3/8” Hex nuts

“Y” (< 7 FT.)

(2) 3/8” x 1-1/4”

Hex bolts and (2) 3/8” Hex nuts

Space center brackets 12” apart

on applications requiring center

coupler assembly

NOTE:

Actual

center brackets

may vary, see

breakdown of

parts.

Maximum Door Size 14’-2” x 12’-1” (Maximum Door Weight 800 lb.)

Cut (2) pieces of perforated angle (1-5/8” x 2-3/8” x 11 GA.) to Dim “Y” and (2) more pieces

at Dim “Y” minus 3”. Bolt the angles together into a “Z” shape using (4) 3/8” x 1-1/4” bolts

and (4) 3/8” nuts. Thru-bolt top and bottom of each “Z” shaped angle to each girt using (4)

3/8” x 1-1/4” bolts and (4) 3/8” nuts. Thru-bolt each center bracket to perforated angle as-

sembly using (3) 3/8” x 1-1/4” bolts and (3) 3/8” nuts, as shown.

(3) 3/8” x 1-1/4”

Hex bolts

Center

brackets

(3) 3/8”

Hex nuts

Heavy perforated angles

(1-5/8” x 2-3/8” x 11ga.)

Girt

Girt

(2) 3/8” x 1-1/4”

Hex bolts and (2)

3/8” Hex nuts

“Y” (< 7 FT.)

(2) 3/8” x 1-1/4”

Hex bolts and (2) 3/8” Hex nuts

Space center brackets 12” apart

on applications requiring center

coupler assembly

(2) 3/8” x 1-1/4”

Hex bolts and (2)

3/8” Hex nuts

NOTE:

Actual

center brackets

may vary, see

breakdown of

parts.

8