Quadrex pan

head screw

Top half of

drawbar

operator

bracket

Bottom half of drawbar

operator bracket

1/4” -20 X 11/16”

Self drilling screws

Bottom

rib

Top rib

Top section

surface

Drawbar operator

bracket arm

Top Section

Tools Required: Power drill, 7/16” Socket driver, 7/16” Wrench, Step ladder,

Tape measure, Safety glasses, Leather gloves

15

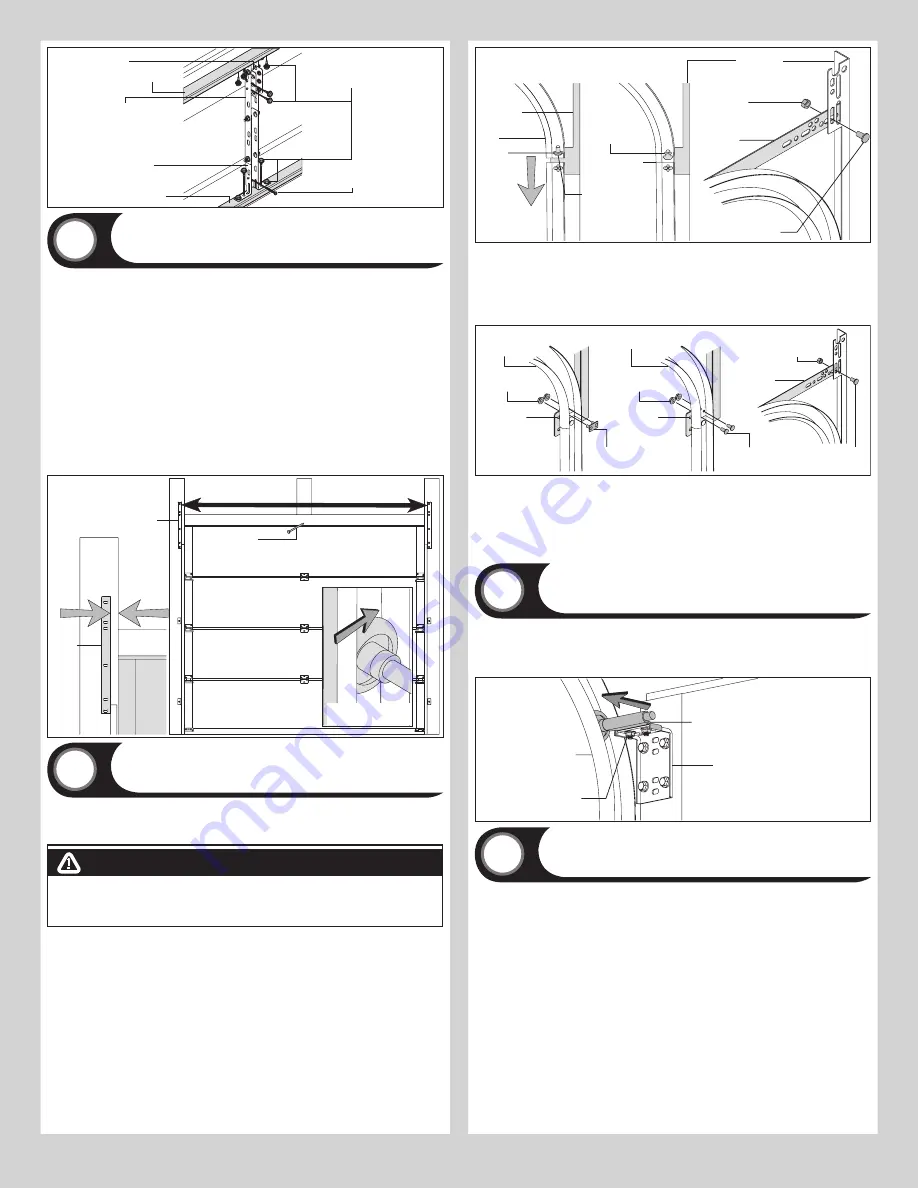

Place the top section in the opening. Temporarily secure the top section by driving a nail in

the header near the center of the door and bending it over the top section. Now, flip up the

hinge leaves, hold tight against section, and fasten center hinges first and end hinges last

(refer to step, Stacking Sections). Vertical track alignment is critical. Position flag angle or wall

angle between 1-11/16” (43 mm) to 1-3/4” (44 mm) from the edge of the door; tighten the

bottom lag screw. Flag angles must be parallel to the door sections. Repeat for other side.

IMPORTANT:

THE DIMENSION BETWEEN THE FLAG ANGLES OR WALL ANGLES MUST BE

DOOR WIDTH PLUS 3-3/8” (86MM) TO 3-1/2” (89 MM) FOR SMOOTH, SAFE DOOR OPERA-

TION.

FOR QUICK INSTALL TRACK:

Complete the vertical track installation by securing the jamb

bracket(s) and tightening the other lag screws. Repeat for other side.

For Fully Adjustable track or Riveted Track: Complete the vertical track installation by securing

the jamb bracket(s) and tightening the other lag screws. Push the vertical track against the

track rollers so that the track rollers are touching the deepest part of the curved side of the

track; tighten all the track bolts and nuts. Repeat for other side.

Top section

Top

section

Nail

Door width

+ 3-3/8” to 3-1/2”

1-11/16”

to 1-3/4”

Flag

angle

Flag angle

Vertical track

against track rollers

Horizontal Tracks

Tools Required: Ratchet wrench, 9/16” 7/16” Socket, 9/16” 7/16” Wrench, Step

ladder, Tape measure, Safety glasses, Leather gloves

16

NOTE:

Depending on your door, you may have Quick Install Flag Angles, Fully Adjustable Flag

Angles or you may have Riveted Vertical Track Assemblies. Refer to Package Contents / Parts

Breakdown, to determine which Flag Angles / Vertical Track Assemblies you have.

WARNING

WARNING

DO NOT RAISE DOOR UNTIL HORIZONTAL TRACKS ARE SECURED AT

REAR, AS OUTLINED IN STEP, REAR BACK HANGS, OR DOOR COULD FALL

FROM OVERHEAD POSITION CAUSING SEVERE OR FATAL INJURY.

IF YOU HAVE QUICK INSTALL FLAG ANGLES:

To install horizontal track, place the curved

end over the top track roller of the top section. Align key slot of the horizontal track with the

Quick Install tab of the flag angle. Push curved portion of horizontal track down to lock in

place.

Horizontal

track

Flag angle

Quick

Install tab

Key slot

Quick

Install tab

in place

Tracks flush

3/8”-16

Hex nut

Horizontal track

angle

3/8”-16 x 3/4”

Truss head bolt

Flag angle

FOR OTHER FLAG ANGLES:

To install horizontal track, place the curved end over the top

track roller of the top section. Align the bottom of the horizontal track with the top of the

vertical track. If you have Quick Install horizontal track, tighten the horizontal track to the flag

angle with a stud plate and (2) 1/4” - 20 flange hex nuts. If you have Universal horizontal

track, tighten the horizontal track to the flag angle with (2) 1/4” - 20 x 9/16” track bolts and

(2) 1/4” - 20 flange hex nuts.

3/8”-16

Hex nut

Horizontal

track angle

3/8”-16 x 3/4”

Truss head bolt

Quick Install

horizontal

track

1/4”-20

Flange hex nuts

Stud

plate

Flag angle

upper slot

1/4”-20 x 9/16”

Track bolts

1/4”-20

Flange hex nuts

Fully Adjustable

horizontal track

Flag angle

upper slot

Next level the horizontal track assembly and bolt the horizontal track angle to the first

encountered slot in the flag angle / angle mount using (1) 3/8” - 16 x 3/4” truss head bolt

and (1) 3/8” - 16 hex nut. Repeat for other side. Next remove the nail that was temporarily

holding the top section in place, installed in step, Top Section.

IMPORTANT:

FAILURE TO REMOVE NAIL BEFORE ATTEMPTING TO RAISE DOOR COULD

CAUSE PERMANENT DAMAGE TO TOP SECTION.

Adjusting Top Fixtures

Tools Required: 7/16” Wrench, Step ladder, Tape measure, Safety glasses,

Leather gloves

17

With horizontal tracks installed, you can now adjust the top fixtures. Vertically align the top

section of the door with the lower sections. Once aligned, position the top fixture slide, out

against the horizontal track. Maintaining the slide’s position, tighten the (2) 1/4” - 20 flange

hex nuts to secure the top fixture slide to the top fixture base. Repeat for other side.

Top fixture slide

(2) 1/4”- 20

Flange hex nuts

Horizontal track

Top section

Top fixture base

TorqueMaster

®

Spring Tube

Tools Required: Safety glasses, Leather gloves

18

TorqueMaster

®

springs come lubricated and pre-assembled inside the TorqueMaster

®

spring

tube. To prepare for install, lay the spring tube assembly on the floor, inside garage, in front of

the door, and with the labeled end to the left. Next, remove the shipping boots from the ends

of the TorqueMaster

®

spring tube.

10

Summary of Contents for TorqueMaster Plus 6100

Page 21: ......