5

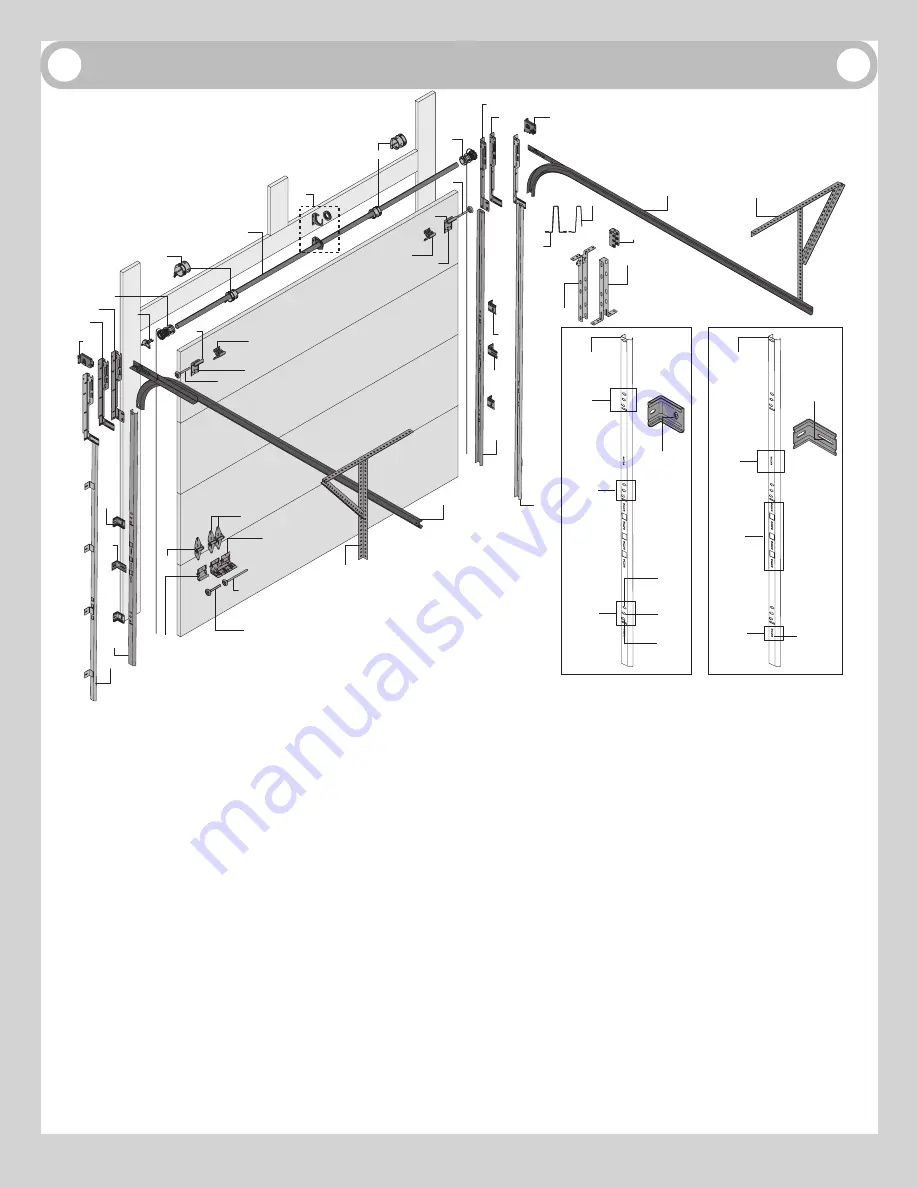

A. FLAG ANGLES (AS REQUIRED):

A1. Fully Adjustable (F.A.) Flag Angles

A2. Quick Install (Q.I.) Flag Angles

B. JAMB BRACKETS (AS REQUIRED):

B1. Fully Adjustable (F.A.) Jamb Brackets

B2. Quick Install (Q.I.) Jamb Brackets

C. TRACK ROLLERS:

C1. Short Stem Track Rollers

C2. Long Stem Track Rollers

D. GRADUATED END HINGES:

D1. Single Graduated End Hinges (S.E.H.), Anti-Pinch

D2. Single Graduated End Hinges (S.E.H.), Industry Standard

D3. Double Graduated End Hinges (D.E.H.), Anti-Pinch

D4. Double Graduated End Hinges (D.E.H.), Industry Standard

E. STACKED SECTIONS:

E1. Top Section

E2. Intermediate(s) Section

E3. Lock Section

E4. Bottom Section

F. TOP FIXTURES (AS REQUIRED):

F1. Top Fixture Bases - (L - Shaped)

F2. Top Fixture Slides - (L - Shaped)

F3. Top Fixture Assemblies

G. STRUT(S) (AS REQUIRED):

G1. Strut (U - shaped)

G2. Strut (A - symmetrical)

H. DRAWBAR OPERATOR BRACKET (FOR TROLLEY OPERATED DOORS):

H1. Top Half Drawbar Operator Bracket

H2. Bottom Half Drawbar Operator Bracket

H3. Drawbar Operator Bracket Arm

I. TRACKS:

I1. Left Hand Horizontal Track Assembly

I2. Right Hand Horizontal Track Assembly

I3. Left Hand Vertical Track

I4. Right Hand Vertical Track

I5. Left Hand Riveted Vertical Track Assembly

I6. Right Hand Riveted Vertical Track Assembly

J. TORQUEMASTER PLUS

®

SPRING ASSEMBLY:

J1. Center Bracket Bushing Assembly

J2. TorqueMaster® Spring Tube (Single Or Double Springs)

J3. Left Hand End Bracket (Double Springs Only)

J4. Right Hand End Bracket (Disconnect Cable Guide)

J5. Left Hand Cable Drum Assembly

J6. Right Hand Cable Drum Assembly

J7. Idler bracket (Single Spring Only)

J8. Left Hand And Right Hand Drum Wraps (Optional)

K. REAR BACK HANGS:

K1. Left Hand And Right Hand Rear Back Hang Assemblies

A2.

B2.

B1.

A1.

C1.

C2.

C1.

D1.

D3.

D4.

E4.

E1.

E2.

E3.

F1.

F2.

F1.

F2.

G1.

G2.

H1.

I2.

I1.

I3.

K1.

K1.

J6.

J1.

J5.

J2.

Lower hole

of hole/

slot pattern

3rd

hole set

Top of vertical

track

Fully

Adjustable

Feature

2nd

hole set

1st

hole set

B2. (Quick

Install

Feature)

3rd hole

set

Top of vertical

track

2nd

hole set

1st hole

set

Middle

hole

Bottom

hole

Top

hole

D2.

H2.

NOTE:

The illustrations shown on this page are general

representations of the door parts. Each specific door

models may have unique variations.

H3.

F3.

F3.

C1.

J8.

J8.

J3.

J7.

I5.

A1.

A2.

B1.

B2.

I4.

J4.

I6.

PARTS BREAKDOWN

Summary of Contents for TorqueMaster Plus 6100

Page 21: ......