hex nut. Repeat for other side.

F.A. jamb

bracket

1/4”- 20 x 9/16”

Track bolt

1/4”- 20

Flange hex nut

Jamb bracket

in place

1st hole set

Lower hole of

hole/ slot pattern

Vertical track

2nd hole set

3rd hole set

Top of track

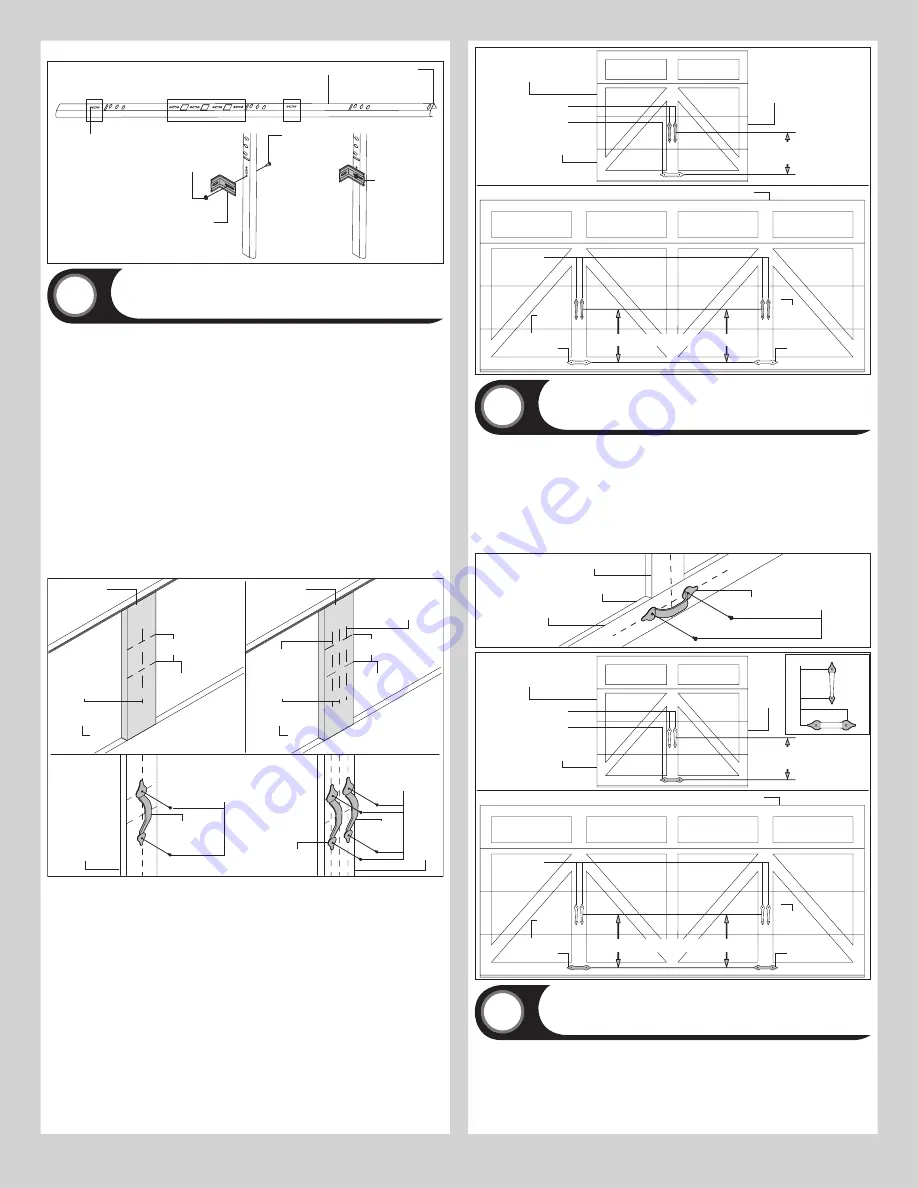

Lift Handles

Tools Required: Power drill, 1/16” Drill bit, Pencil, Tape measure, Safety glasses,

Leather gloves

6

NOTE:

Refer to door section identification, located in the pre-installation section of this

manual or refer to Parts Breakdown on page 2.

Starting with the lock section, measure the width of the center stile which will receive the

lift handle(s). Divide that measurement in half and mark a vertical line onto the center of the

stile.

NOTE:

If you are installing two lift handles on the center stile, you will need to measure from

the edge of the center stile to the center line mark. Divide that measurement in half and draw

a second and third vertical line parallel to the previously made center line mark.

Now, measure the height of the panel. Divide that measurement in half and mark a horizontal

line, intersecting the vertical line(s) previously marked. Measure up 3 7/8” from the intersect-

ing line(s) and mark another horizontal line.

Use the point(s) where the top horizontal line intersects the vertical line(s) to locate the top

hole of the lift handle(s). Using the lift handle as a template, mark this location onto the

center stile. Keeping the lift handle aligned with the vertical line, mark the lower lift handle

hole onto the center stile. Drill 1/16” pilot holes at the marked hole locations. Fasten both lift

handles to the center stile using #10 X 5/8” pan head self tapping screws.

If the door came with two sets of lift handles repeat the same process for the other lift

handles.

Lock section

Lock section

(2) #10 x 5/8” Pan

head self tapping

screws

(4) #10 x 5/8” Pan

head self tapping

screws

Center line

Center line

Vertical

line

Vertical

line

Lift

handle

Lift

handle

Lift

handle

Center stile

Center

stile

Center stile

Center stile

3-7/8”

3-7/8”

Horizontal

line

Horizontal

line

Lift handles

Bottom section

Typical placement of lift

handles referenced on

single wide doors

Lock

section

Typical placement of lift handles referenced on double wide doors

20” Minimum to

30” Maximum

20” Minimum to 30” Maximum

Pull handle

Lift handles

Bottom

section

Lock

section

Pull handle

Pull handle

Pull Handles

Tools Required: Power drill, 1/16” Drill bit, Pencil, Tape measure, Safety glasses,

Leather gloves

7

Locate and mark the horizontal and vertical center on the bottom rail of the bottom section,

on single car doors.

Center the pull handle using the vertical and horizontal lines as referenced on the bottom

section rail. Using the pull handle as a template, mark the two hole locations in the pull

handle onto the horizontal line of the bottom section rail. Drill 1/16” pilot holes at the marked

hole locations. Fasten pull handle(s) using (2) #10 X 5/8” pan head self tapping screws.

If your door came with two pull handles, locate them directly below the lift handles and

repeat the installation process.

Bottom section

(2) #10 X 5/8” Pan

head self tapping

screws

Bottom rail

Center stile

Pull handle

Lift handles

Bottom section

Typical placement of pull

handle referenced on

single wide doors

Lock

section

Typical placement of pull handles referenced on double wide doors

20” Minimum to

30” Maximum

20” Minimum to 30” Maximum

Pull handle

Lift handles

Bottom

section

Lock

section

Pull handle

Pull handle

Caulk

Cable Drum Assemblies and Track Rollers

Tools Required: Tape measure, Safety glasses, Leather gloves

8

NOTE:

Refer to door section identification, located in the pre-installation section of this

manual or refer to Parts Breakdown.

NOTE:

Cable drum assemblies are marked right and left hand.

7

Summary of Contents for TorqueMaster Plus 6100

Page 21: ......