WARNING

WARNING

FAILURE TO ENSURE TIGHT FIT OF CABLE LOOP OVER MILFORD PIN

COULD RESULT IN COUNTERBALANCE LIFT CABLE COMING OFF THE PIN,

ALLOWING THE DOOR TO FALL, POSSIBLY RESULTING IN SEVERE OR

FATAL INJURY.

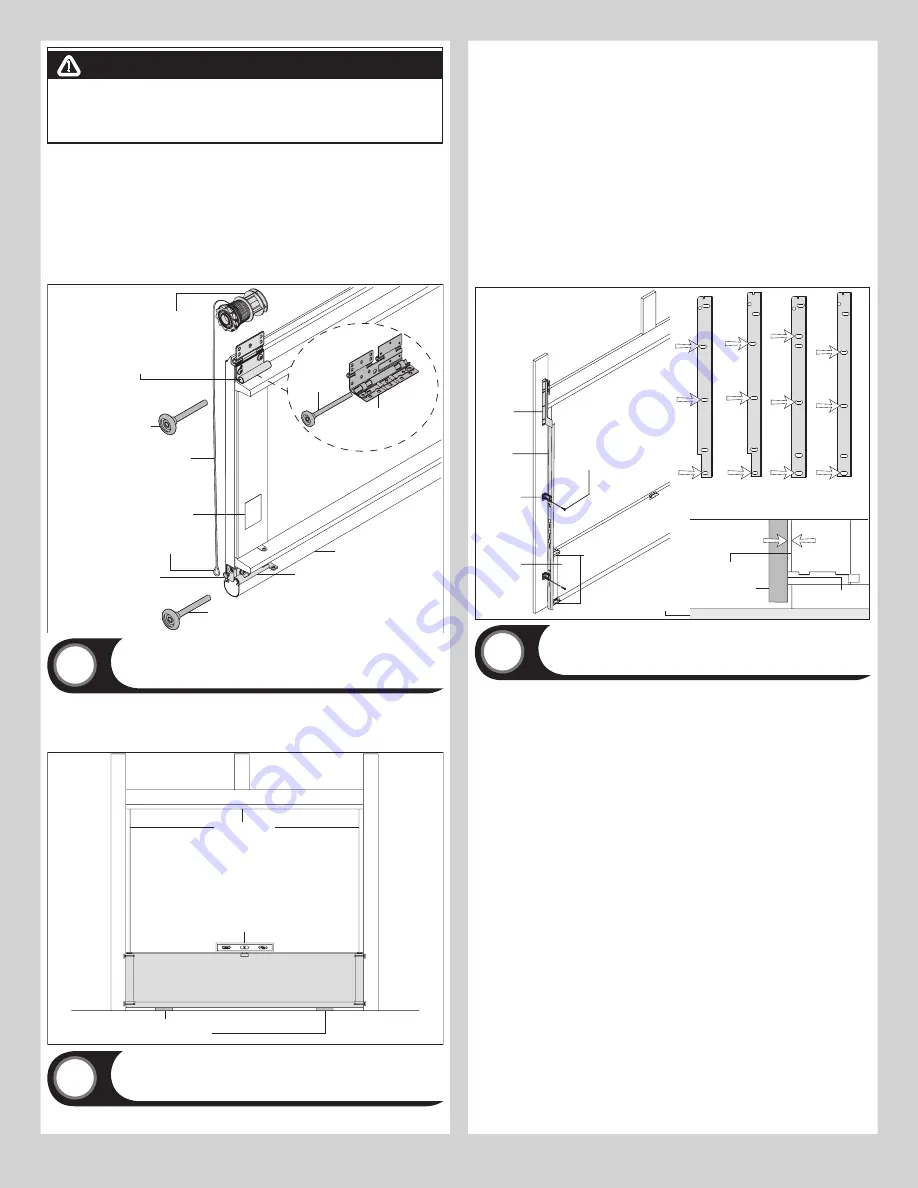

Uncoil the counterbalance lift cables from the cable drum assemblies, making sure you place

the left hand cable loop on the left hand milford pin of the bottom corner bracket and the

right hand cable loop on the right hand milford pin of the bottom corner bracket.

NOTE:

Check to ensure cable loops fits tightly over the milford pins.

Insert a short stem track roller into the bottom corner brackets and another into the #1

graduated end hinges at the top of the bottom section.

NOTE:

Larger doors will use long stem track rollers with double graduated end hinges.

NOTE:

Verify bottom weather seal is aligned with bottom section. If there is more than 1/2”

excess weather seal on either side, trim weather seal even with bottom section.

Double graduated

end hinge (Hinge

tube)

Long stem

track roller

Counterbalance lift cable

Short stem track roller

#1 Single graduated end hinge

(Hinge tube)

Bottom corner bracket

warning label

Milford pin

Cable loop

Bottom weather seal

Bottom corner

bracket

Left hand cable

drum assembly

Bottom

section

Short stem track roller

Bottom Section

Tools Required: Tape measure, Level, Wooden shims (if necessary), Safety

glasses, Leather gloves

9

Center the bottom section in the door opening. Level the section using wooden shims (if

necessary) under the bottom section. When the bottom section is leveled, temporarily hold it

in place by driving a nail into the jamb and bending it over the edge of the bottom section on

both sides.

Weather seal

Level

Bottom section

Wooden shims

(If necessary)

Vertical Tracks

Tools Required: Power Drill, 3/16” Drill bit, 7/16” Socket driver, Tape measure,

Level, Step ladder, Safety glasses, Leather gloves

10

NOTE:

Depending on your door, you may have Quick Install Flag Angles, Fully Adjustable Flag

Angles or you may have Riveted Vertical Track Assemblies. Refer to Package Contents / Parts

Breakdown, to determine which Flag Angles / Vertical Track Assemblies you have.

IMPORTANT:

IF YOUR DOOR IS TO BE INSTALLED PRIOR TO A FINISHING CONSTRUCTION

OF THE BUILDING’S FLOOR, THE VERTICAL TRACKS AND THE DOOR BOTTOM SECTION

ASSEMBLY SHOULD BE INSTALLED SUCH THAT WHEN THE FLOOR IS CONSTRUCTED, NO

DOOR OR TRACK PARTS ARE TRAPPED IN THE FLOOR CONSTRUCTION.

IMPORTANT:

THE TOPS OF THE VERTICAL TRACKS MUST BE LEVEL FROM SIDE TO SIDE.

IF THE BOTTOM SECTION WAS SHIMMED TO LEVEL IT, THE VERTICAL TRACK ON THE

SHIMMED SIDE MUST BE RAISED THE HEIGHT OF THE SHIM.

Starting on the left hand side of the bottom section, remove the nail. Position the left hand

vertical track assembly over the track rollers of the bottom section. Make sure the coun-

terbalance lift cable is located between the track rollers and the door jamb. Drill 3/16” pilot

holes into the door jamb for the lag screws.

For Quick Install Flag Angles, Fully Adjustable Flag Angles or Riveted Vertical Track As-

semblies: Loosely fasten jamb brackets and flag angle to the jamb using 5/16” x 1-5/8” lag

screws. Tighten lag screws, securing the bottom jamb bracket to jamb, maintain 3/8” to 5/8”

spacing, between the bottom section and vertical track. Hang counterbalance lift cable over

flag angle. Repeat same process for other side.

Vertical

track

assembly

Jamb

bracket

Flag

angle

Flag angle lag screw locations

5/16” x 1-5/8”

Lag screws

Bottom

section

Track

rollers

12R FA

3/8” to 5/8”

Spacing

Bottom section

Vertical track

15R FA

15R QI

12R QI

Floor

Track roller

Stacking Sections

Tools Required: Power drill, 7/16” Socket driver, Tape measure, Level, Step lad-

der, Safety glasses, Leather gloves

11

NOTE:

The sections can be identified by the graduation of the factory installed graduated end

hinges. The smallest graduated end hinge on section should be stacked on top of the bottom

section, with each graduated end hinge increasing as the sections are stacked, see Door

Section Identification / Parts Breakdown.

NOTE:

Make sure graduated end and center hinges are flipped down, when stacking another

section on top.

NOTE:

Larger doors will use long stem track rollers with double graduated end hinges.

Place track rollers into graduated end hinges of remaining sections.

With assistance, lift second section and guide the track rollers into the vertical tracks. Lower

section until it is seated against bottom section. Flip hinges up. Fasten center hinge(s) first;

then end hinges last using 1/4” - 14 x 5/8” self tapping screws.

NOTE:

To prevent center hinge leaf(s) from rotating, first secure the top middle hole of the

center hinge leaf with one 1/4” - 14 x 5/8” self-tapping screw then secure the other two

holes.

NOTE:

Larger doors with double graduated end hinges, fasten both hinges to connect the

sections using 1/4” - 14 x 5/8” self-tapping screws.

Repeat same process for other sections, except top section.

IMPORTANT:

PUSH & HOLD THE HINGE LEAFS SECURELY AGAINST THE SECTIONS WHILE

SECURING WITH 1/4” - 14 X 5/8” SELF TAPPING SCREWS. THERE SHOULD BE NO GAP

BETWEEN THE HINGE LEAFS AND THE SECTIONS.

NOTE:

Install lock at this time (sold separately). See optional installation step, Side Lock.

8

Summary of Contents for TorqueMaster Plus 6100

Page 21: ......