Left hand

cable

drum

assembly

Right hand cable

drum assembly

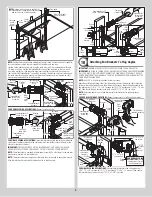

NOTE:

Working with a partner as needed, lift

the TorqueMaster

®

spring tube assembly up

and rest it on top of the flag angles.

Flag angle

Flag

angle

Center

bracket

Label

NOTE:

Cable drum assemblies are marked right and left hand. Cable drums and TorqueMas-

ter

®

spring tube assembly are cam shaped to fit together only one way.

Starting on the right hand side, pre-wrap the cable drum with the counterbalance lift cable

1/2 wrap, as shown. Position the TorqueMaster

®

spring tube assembly so the cam peak

is pointing straight up. Slide the cable drum over the winding shaft until the cable drum

seats against the TorqueMaster

®

spring tube assembly. The winding shaft must extend past

the cable drum far enough to expose the splines and the grooves. Align the winding shaft

grooves with the round notch in the flag angle.

Right hand

cable drum

Right

hand

cable

drum

TorqueMaster

®

spring tube

assembly

Counterbalance

lift cable 1/2

wrap

Counterbalance

lift cable

Winding

shaft

Cam peak

straight up

Splines

Groove

Round notch

in flag angle

5”

Winding

shaft

Cam

peak

straight

up

Insert winding

shaft into flag

angle

Bearing

FOR DOUBLE SPRING APPLICATIONS:

Repeat for left hand side.

Left hand

cable drum

TorqueMaster

®

spring tube

assembly

Counterbalance lift

cable 1/2 wrap

Counterbalance

lift cable

Winding

shaft

5”

Left hand

cable drum

Splines

Groove

Round notch

in flag angle

Winding

shaft

Cam

peak

straight

up

Insert winding

shaft into flag

angle

Bearing

FOR SINGLE SPRING APPLICATIONS:

Insert the idler bracket into the left hand cable drum.

Lightly press the idler bracket into the cable drum until two distinct clicks are heard, or the

bracket is inserted all the way.

IMPORTANT:

ENSURE THE SNAPS ON THE IDLER BRACKET (LEFT HAND SIDE) ARE EN-

GAGED INTO THE LEFT HAND CABLE DRUM, SO THAT IT DOES NOT COME BACK OUT.

NOTE:

The idler bracket is designed for permanent assembly. Do not attempt to remove idler

bracket once inserted into the cable drum.

NOTE:

The idler bracket must extend past the cable drum far enough to expose the groove.

Align the idler bracket groove with the round notch in the flag angle.

Left hand

cable drum

TorqueMaster

®

spring tube

assembly

Counterbalance lift

cable 1/2 pre-wrap

Counterbalance

lift cable

Idler

bracket

Cam peak

straight up

Round

notch

Groove

Flag

angle

Snaps

Idler

bracket

Flag

angle

Bearing

Idler

bracket

Snaps

Groove

Left hand

cable drum

Idler

bracket

Snaps

Groove

Left

hand

cable

drum

Attaching End Brackets To Flag Angles

18

IMPORTANT:

WARNING TAGS MUST BE SECURELY ATTACHED TO END BRACKET(S).

IMPORTANT:

FOR SINGLE SPRING DOORS, ENSURE THE LEFT HAND CABLE DRUM BEARING

IS ALL THE WAY TO THE LEFT AND UP AGAINST THE FLAG ANGLE. IF THE CABLE DRUM IS

PULLED AWAY FROM THE FLAG ANGLE, THEN THE IDLER BRACKET CAN RUB AGAINST THE

CABLE DRUM CAUSING NOISE.

NOTE:

Drill 3/16” pilot holes into header for the lag screws.

Beginning with the right hand side, slide the end bracket onto the winding shaft so that the

splines in the ratchet wheel fit onto the winding shaft grooves. Attach the end bracket to the

flag angle using (1) 5/16” - 18 x 3/4” carriage bolt, (1) 5/16” washer and (1) 5/16” - 18 hex

nut. Then secure the end bracket to the jamb using (1) 5/16” x 1-5/8” lag screw.

NOTE:

If ratchet wheel falls out of end bracket, refer to illustration for proper insertion

orientation.

FOR DOUBLE SPRING APPLICATIONS:

Repeat same process for left hand end bracket.

Grooves

Warning

tag

Disconnect cable

guide hole

Splines

Winding

shaft

Right

hand

end

bracket

Flag

angle

TorqueMaster

®

spring tube

assembly

Right hand

cable drum

Ratchet wheel

(oriented correctly)

FOR DOUBLE SPRING

APPLICATIONS:

Repeat

same process for left

hand end bracket.

5/16”

Washer

5/16”

Hex nut

Winding

shaft

5/16” -18 x 3/4”

Carriage bolt

TorqueMaster

®

spring tube

assembly

Right hand

cable drum

5/16” x 1-5/8”

Lag screw

Right

hand end

bracket

Flag

angle

Flag

angle

FOR SINGLE SPRING APPLICATIONS:

Secure the idler bracket to the flag angle using (1)

5/16” - 18 x 3/4” carriage bolt, (1) 5/16” washer and (1) 5/16” - 18 hex nut. Then secure

the idler bracket to the jamb using (1) 5/16” x 1-5/8” lag screw.

8