8

Cab

le Dr

um

No sp

ace

between

Ratch

et

Pawl

and Cab

le D

rum

indica

tes engagem

ent

Cab

le Drum

Ratch

et Paw

l

ENGAG

ED SIDE VIEW

No sp

ace

between

Ratchet

Paw

l and

Cabl

e Dru

m

ENGAGE

D UNDE

RNE

ATH

VIEW

Space

between R

atchet Pa

wl

and

Cable

Drum

non-

indicates eng

agement

Cab

le Dr

um

Ratche

t Paw

l

DISENG

AGED

SIDE VIEW

No sp

ace

between

Ratchet Paw

l and

DISENGAGED

UNDE

RNE

ATH VIEW

UPPER

POSIT

ION

LOWER POSIT

ION

LOWER

POSIT

ION SIDE

VIEW

UPP

ER POSITION

SIDE VIEW

Ratche

t Paw

l in Lowe

r Po

sition

Ratch

et Paw

l in Up

per Pos

ition

Use these Illu

stration

, in conj

unction w

ith th

e Instr

uction

s on th

e oth

er si

de of

this la

bel.

WAR

NING

Rachet Brack

et is under

EXTREM

E SPRI

NG

TENS

ION

.

To avoid possible se

vere or

fata

l injury

,

DO NO

T

remov

e

fasteners

from ratchet

bracket

until sp

ring(

s) are fu

lly

wnwound

.

To safely un

wind spr

ing(s)

read

and fo

llow the dire

ctions in

the

installati

on in

structio

ns/owners

ma

nual.

DO NO

T REMOVE

THIS

TAG

.

Spring Turns

Door Height

Spring Turns

(6’ - 0”)

14

(6’ - 3”)

14 - 1/2

(6’ - 5”)

15

(6’ - 6”)

15

(6’ - 8”)

15 - 1/2

(6’ - 9”)

15 - 1/2

(7’ - 0”)

16

(7’ - 3”)

16 - 1/2

(7’ - 6”)

17

(7’ - 9”)

17 - 1/2

(8’ - 0”)

18

Number of Installed Spring Turns

Now, lift door and check it’s balance.

if door raises off the floor under spring

tension alone, then reduce spring tension until door rest on the floor. if the

door is hard to raise or drifts down on its own, then add spring tension.

Anytime spring adjustments are made, ratchet pawl knob must be in the

upper position to add/remove required number of spring turns. To adjust

springs, only add or remove a maximum of 3/10 of a turn (three teeth of

ratchet wheel) at a time. Both sides need to be adjusted equally on double

spring doors.

iMPORTAnT:

BE PREPARED TO HOLD THE FuLL TENSiON OF THE SPRiNG,

WHEN ADjuSTiNG SPRiNG TENSiON.

iMPORTAnT:

DO NOT ADD OR REMOVE MORE THAN 1 SPRiNG TuRN

(1 SPRiNG TuRN EquALS 10 TEETH ON RATCHET WHEEL) FROM THE

RECOMMENDED NuMBER OF TuRNS SHOWN ON THE SPRiNG TuRN CHART.

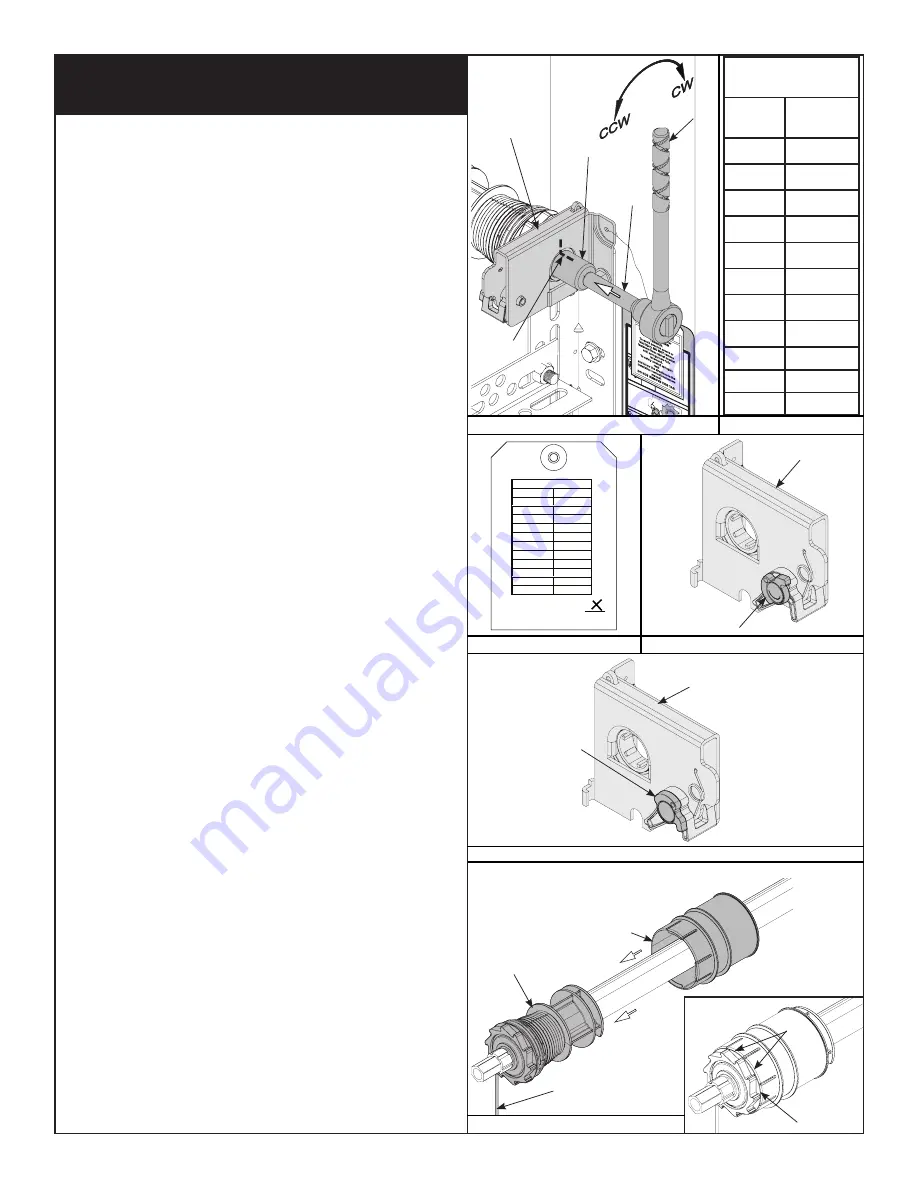

Add Spring Tension:

The ratchet wheel is made of 10 teeth. To add spring

tension, ensure the ratchet and socket is set so that it will tighten counter

clockwise on the right hand side, and clockwise on the left hand side. Place

the ratchet with 5/8” socket onto the winding shaft, pull down to add 3/10 of

a turn. Watch as three teeth of the ratchet wheel pass over the pawl, creating

three “clicks”.

Remove Spring Tension:

To remove spring tension, ensure the ratchet and

socket is set so that it will tighten counter clockwise on the right hand side

and clockwise on the left hand side. it is recommended that a regular 5/8”

wrench be used. Place the wrench onto the winding shaft. Pull down on the

wrench to relieve pressure between the pawl and the ratchet wheel. Push

in on the pawl to allow the three ratchet wheel teeth to pass by the pawl, as

you carefully allow the wrench to be rotated upward by the spring tension.

Release the pawl to allow it to engage with the ratchet wheel.

if the door still does not operate easily, lower the door into the closed

position, uNWiND SPRiNG(S) COMPLETELY, and recheck the following items:

1.)

Check the door for level.

2.)

Check the TorqueMaster

®

tube and flagangles for level and plumb.

3.)

Check the distance between the flagangles. it must be door width plus

3-3/8” to 3-1/2”.

4.)

Check the counterbalance cables for equal tension. Adjust if necessary.

5.)

Rewind the spring(s).

6.)

Make sure door isn’t rubbing on jambs.

To install drum wraps, position the left hand drum wrap over the left hand

drum, align with counterbalance cable; slide groove in drum wrap towards

the left until tabs snap over drum in between drum and ratchet gear, as

shown in

fig. 4.1

. Repeat for right hand side.

TorqueMaster

®

Plus Single and Double Spring Replacement

- Continued

End Bracket

Ratchet

3”

Extension

5/8” Socket

Marks

Pawl knob in

Lower Position

End Bracket

Pawl knob in

upper Position

End Bracket

Drum Wrap

(Left Hand)

Drum

(Left Hand)

Counterbalance

Cable

Groove

in Drum

Tabs

REcOMMEndEd

SPRing TURnS

door

Height

Spring Turns

6’-0”

14

6’-3”

14-1/2

6’-5”

15

6’-6”

15

6’-8”

15-1/2

6’-9”

15-1/2

7’-0”

16

7’-3”

16-1/2

7’-6”

17

7’-9”

17-1/2

8’-0”

18

fig. 3.6

fig. 3.8

fig. 3.9

fig. 4.0

fig. 4.1

fig. 3.7