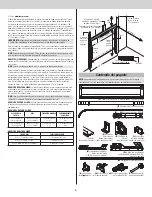

ATTACHING END BRACKETS TO FLAG ANGLES

15

IMPORTANT:

Warning tags must be securely attached to end bracket(s).

IMPORTANT:

For single spring doors, ensure the left hand cable drum bearing is all the

way to the left and up against the flag angle. If the cable drum is pulled away from the flag

angle, then the idler bracket can rub against the cable drum causing noise.

NOTE:

Drill 3/16” pilot holes into header for the lag screws.

STEP 15 INSTRUCTIONS

15a.

Beginning with the right hand side, slide the end bracket

(I4.)

onto the winding shaft so

that the splines in the ratchet wheel fit onto the winding shaft grooves.

15b.

Attach the end bracket to the flag angle

(A1.)

using (1) 5/16” - 18 x 3/4” carriage bolt,

(1) 5/16” washer and (1) 5/16” - 18 hex nut. Then secure the end bracket to the jamb using

(1) 5/16” x 1-5/8” lag screw.

NOTE:

If ratchet wheel falls out of end bracket, refer to illustration for proper insertion

orientation.

15c.

FOR DOUBLE SPRING APPLICATIONS:

Repeat same process for left hand end

bracket.

Grooves

Warning

tag

Splines

Winding

shaft

(I4.)

Right

hand end

bracket

Flag

angle

Spring tube

assembly

Right hand

cable drum

Ratchet wheel

(oriented correctly)

FOR DOUBLE SPRING

APPLICATIONS:

Repeat

same process for left

hand end bracket.

5/16”

Washer

5/16”

Hex nut

Winding

shaft

5/16” -18 x 3/4”

Carriage bolt

Spring tube

assembly

Right hand

cable drum

5/16” x 1-5/8”

Lag screw

Right

hand end

bracket

Flag

angle

(A1.)

Flag

angle

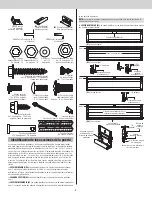

FOR SINGLE SPRING APPLICATIONS:

15d.

Secure the idler bracket

(I6.)

to the flag angle using (1) 5/16” - 18 x 3/4” carriage bolt,

(1) 5/16” washer and (1) 5/16” - 18 hex nut. Then secure the idler bracket to the jamb using

(1) 5/16” x 1-5/8” lag screw.

Spring tube

assembly

Left hand

cable drum

(I6.)

Idler

bracket

Flag

angle

5/16” x 1-5/8”

Lag screw

5/16” -18 x 3/4”

Carriage bolt

5/16” Washer

5/16” Hex

nut

Flag

angle

Left hand

cable drum

Bearing

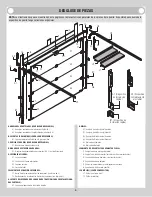

ATTACHING CENTER BRACKET TO WALL

16

IMPORTANT:

Spring tube must be level before securing center bracket bushing assembly

to header.

NOTE:

Drill 3/16” pilot holes into header for the lag screws.

STEP 16 INSTRUCTIONS

16a.

To locate the center bracket bushing assembly, mark the header halfway between the

flag angles and level the spring tube. Fasten the center bracket bushing assembly to the

header using (2) 5/16” x 1-5/8” lag screws.

Spring tube

Center bracket

bushing assembly

Level

(2) 5/16” x 1-5/8”

Lag screws

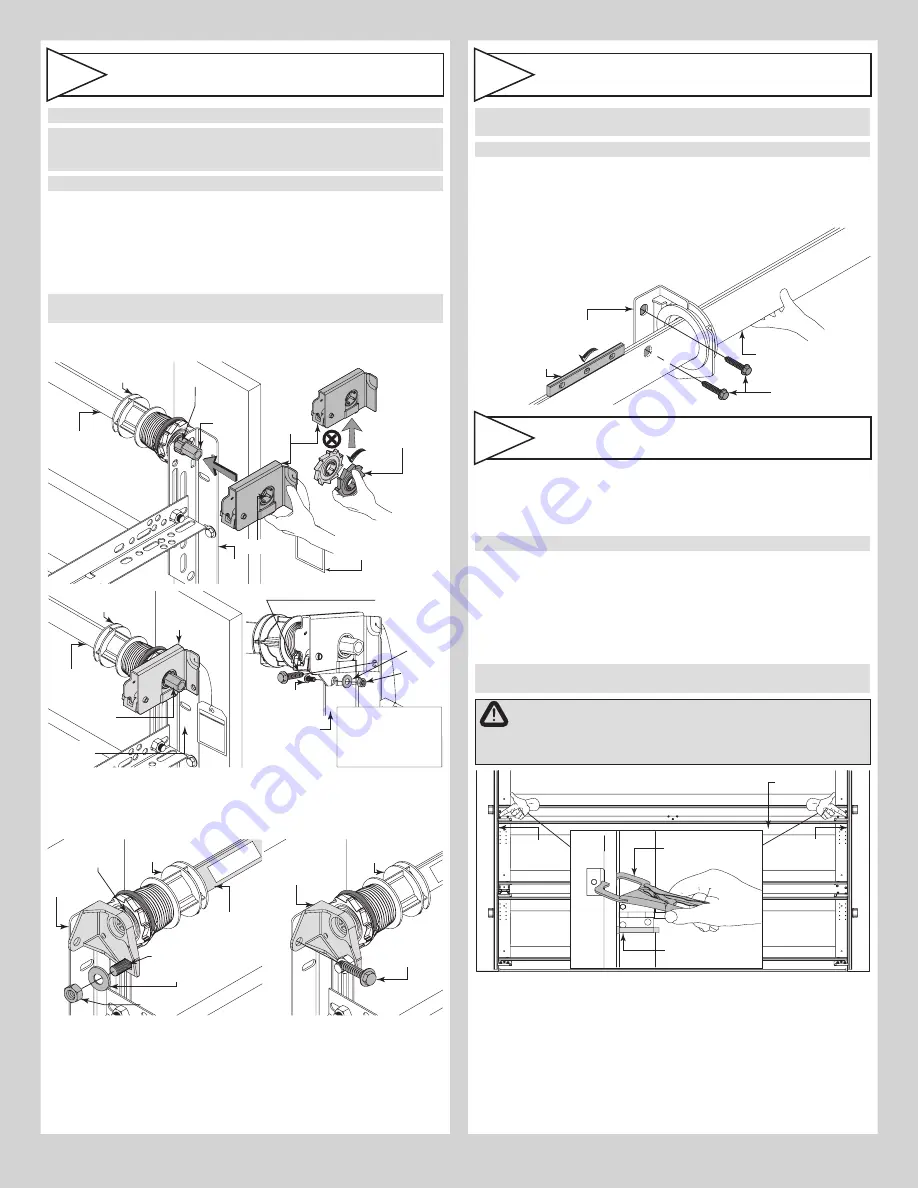

SECURING DOOR FOR WINDING THE SPRING(S)

17

STEP 17 INSTRUCTIONS

17a.

With the door in the fully closed position, place locking pliers onto both vertical tracks

(H5.) (H6.)

just above the third track roller

(C1.)

. This is to prevent the garage door from

rising while winding spring(s).

NOTE:

Check the following before attempting to wind the spring(s):

17b.

Counterbalance lift cables are secured at bottom corner brackets.

17c.

Counterbalance lift cables are routed unobstructed to cable drums.

17d.

Counterbalance lift cables are correctly installed and wound onto cable lift drums.

17e.

Spring tube is installed correctly.

17f.

Review the Winding Spring Turn Chart in Step Winding Spring(s), to determine the

number of spring turns required.

NOTE:

Door MUST be closed and locked when winding or making any adjustments to the

spring(s).

WARNING

FAILURE TO PLACE LOCKING PLIERS ONTO VERTICAL TRACK CAN

ALLOW DOOR TO RAISE AND CAUSE SEVERE OR FATAL INJURY.

(C1.)

Short stem

track rollers

(E4.)

Bottom

section

(E3.)

Second

section

Locking pliers attached

to inner and outer rail

of vertical track

(E2.)

Intermediate section

(H5.)

Vertical track

(H6.)

Vertical

track

12