DOOR INSTALLATION INSTRUCTIONS

BEFORE INSTALLING YOUR DOOR, BE CERTAIN THAT YOU HAVE READ AND FOL-

LOWED ALL OF THE INSTRUCTIONS COVERED IN THE PRE-INSTALLATION SECTION

OF THIS MANUAL. FAILURE TO DO SO MAY RESULT IN AN IMPROPERLY INSTALLED

DOOR.

NOTE:

Reference TDS 160 for general garage door terminology at

www.dasma.com

.

IMPORTANT:

IF THE DOOR WILL BE EXPOSED TO A SIGNIFICANT AMOUNT OF ROAD SALT,

PAINT THE BARE GALVANIZED BOTTOM WEATHER STEEL RETAINER TO INHIBIT RUSTING.

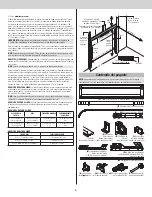

VERTICAL TRACK ASSEMBLY

1

NOTE:

Depending on your door, you may have Quick Install Flag Angles or Fully Adjustable

Flag Angles. Refer to either the images below, Package Contents or Breakdown of Parts, to

determine which Flag Angles you have.

NOTE:

The bottom jamb bracket is always the shortest bracket, while the center jamb

bracket is the next tallest. If three jamb brackets per side are included with your door, you

will have received a top jamb bracket, which is the tallest.

STEP 1 INSTRUCTIONS

FOR DOORS WITH QUICK INSTALL FLAG ANGLES:

1a.

Place the lower Quick Install tab of the left hand flag angle

(A1.)

in the Quick Install

feature of the left hand vertical track

(H3.)

. Give the flag angle 1/4 turn to lock in place.

1/4 Turn

(H3.)

Left hand

vertical track

(A1.)

Left hand quick

install flag angle

FOR DOORS WITH FULLY ADJUSTABLE FLAG ANGLE:

1a.

Hand tighten the left hand flag angle

(A2.)

to the left hand vertical track

(H3.)

using (2)

1/4” - 20 x 9/16” track bolts and (1) stud plate.

Stud Plate

(2) 1/4”- 20

Flange hex nuts

12” Radius track

15” Radius track

(2) 1/4”- 20 Flange hex nuts

Slot

Slot

12” Or 15”

Radius

(H1.)

Horizontal

track

(A2.)

Left hand fully

adjustable flag angle

(H5.)

Left

hand vertical

track

(H5.)

Left

hand vertical

track

1b.

Measure the length of the vertical tracks. Using the jamb bracket schedule, determine

the placement of the jamb brackets

(B1.)

for your door height and track length.

1c.

To install the jamb brackets, align the Quick Install tab on the Quick Install jamb bracket

with the Quick Install feature in the vertical track and turn the bracket perpendicular to the

track so the mounting flange is toward the back (flat) leg of the track.

1d.

Repeat the same process for right hand side.

6’5”

6’0”

6’8”

72” (1829 mm)

69” (1753 mm)

64” (1626 mm)

3

3

5

B

B

M

6

6

6

M

M

B

NA

NA

NA

B

B

M

7’0”

7’6”

7’3”

8’0” 4-SEC

7’9”

85” (2159 mm)

82” (2083 mm)

79” (2007mm)

88” (2235mm)

76” (1930 mm)

8’0” 5-SEC

B= BOTTOM HOLE, M= MIDDLE HOLE, T= TOP HOLE

88” (2235 mm)

3

3

3

3

3

3

B

B

B

M

B

B

5

5

5

6

7

7

B

B

B

T

T

T

6

6

6

7

NA

8

B

B

B

M

B

T

JAMB BRACKET SCHEDULE

2ND SET

1ST SET

3RD SET

TRACK LENGTH

DOOR

HEIGHT

1/4

Turn

Left hand

jamb bracket

3rd

Set

1st

Set

2nd Set

Bottom

hole

Top

hole

Middle

hole

(H3.)

Left

hand

vertical

track

(B1.)

Left hand

jamb bracket

ATTACHING HORIZONTAL TRACK ANGLES

2

NOTE:

For larger doors, a full length horizontal track angle may not already be spot welded

to the horizontal track

(H1.)(H2.)

. If the horizontal track angle is not welded, the horizontal

track angle will be installed, as shown.

STEP 2 INSTRUCTIONS

2a.

Position the left hand horizontal track angle

(H3.)

, as shown.

2b.

Place the Quick Install tabs of the horizontal track angle in the key slot of the left hand

horizontal track

(H1.)

. Using a hammer, tap the horizontal track angle towards the curved end

of the track until the alignment hole in the track and angle are aligned.

2c.

Repeat for other side. Set tracks aside.

(H3.)

Left hand

horizontal track angle

Key slots

(H1.)

Left hand

horizontal track

Quick

Install tabs

Quick Install tabs

in place

Left hand horizontal

track angle

Quick

Install tabs

Or

NOTE:

Repeat the same

process for the right hand side.

6