© Copyright

2008-03-20 V0 Rev.01.0

- 20 -

WT004139

Configuration parameters

The proper functioning of the head is guaranteed by programming a series of configuration parameters,

divided into two groups:

•

accessible parameters;

•

non-accessible parameters (protected by a metric seal);

To set these parameters it is necessary to use the four buttons on the display.

The final part of the manual indicates the operating procedures to change prices and define the operating

modes of the dispenser.

For all other functions refer to the specific manual of the head.

Error conditions

During operation, the head performs a constant error diagnostic. Once an error is identified, the head:

•

immediately stops fuelling (blocking condition);

•

lights a red led;

•

shows the error code corresponding to the identified error on the unit price display;

When an error is identified during fuelling, the unit price displays the «bloc» message and the error code is

displayed only after the dispensing selector is turn to OFF.

Electrical components used in hazardous areas

The dispenser can be used in potentially explosive areas due to the presence of gas.

The whole dispenser is marked CE/ATEX as a device of group II, category 3 G even in compliance with

prEN13638.

For safety, the electrical system uses single components (junction boxes, meter, pressure transmitter,

electro-valves, etc.) suitable for group II, category 2 G.

MAINTENANCE

The dispenser leaves the factory only after passing accurate tests (hydraulic and electrical). A correct

installation and use should guarantee proper functioning.

In any case, in order to maintain the dispenser’s optimal conditions in time and guarantee its safety, the

station manager must check the components listed in the table below periodically.

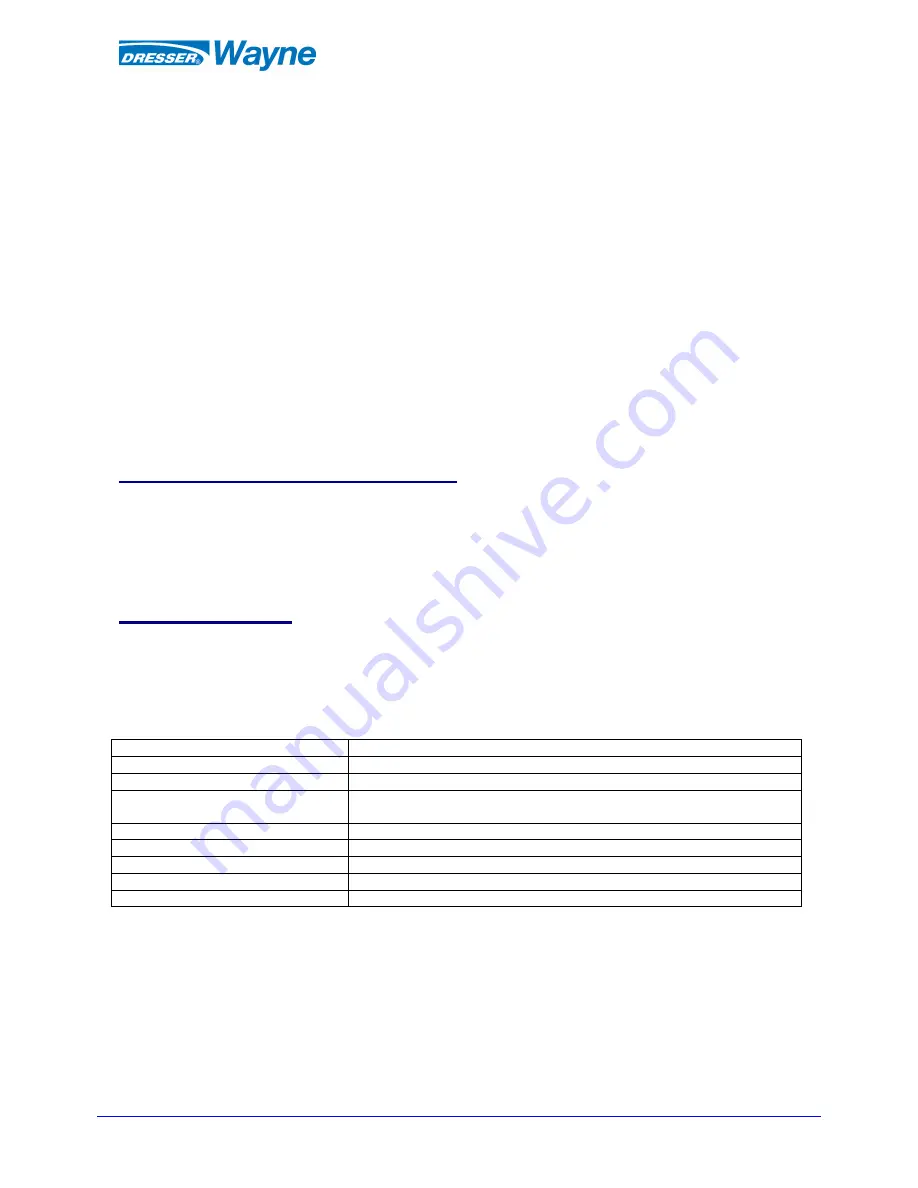

Component

Intervention

Pneumatic actuator

Periodically replace all gaskets and piston slides; check cylinder wear

Electronics and measuring tube

Perform measuring tests during official inspections

Filter

Disassemble the filter and clean filtering element or replace it if

damaged

Delivery hose

Replace if damaged

Three-way valve

Check sealing of gaskets and replace if damaged

Check valve

Check sealing

Vent valve

Check sealing of gaskets and replace if damaged

Gas inlet valve

Check sealing of gaskets and replace if damaged

The operational life of these components depends of different conditions such as, for example, the quality of

the product being dispensed, environmental characteristics, climatic conditions and method of use.

The periodicity of maintenance operations must be established as a consequence.

Maintenance operations must be performed exclusively by qualified technicians, trained for this purpose.

Maintenance operators will have to use all personal safety protection (proper shoes, gloves and glasses, etc).

Maintenance operators must be knowledgeable of all measures to adopt in order to prevent any explosive

reaction in the presence of gas (for example, avoid naked flames, sparks, and electrostatic discharge).

Summary of Contents for GLOBAL VISTA CNG

Page 1: ...EN WT004139 2008 03 20 V0 Rev 01 0 Global Vista CNG Instruction Manual ...

Page 10: ... Copyright 2008 03 20 V0 Rev 01 0 10 WT004139 ...

Page 11: ... Copyright 2008 03 20 V0 Rev 01 0 11 WT004139 ...

Page 12: ... Copyright 2008 03 20 V0 Rev 01 0 12 WT004139 ...

Page 13: ... Copyright 2008 03 20 V0 Rev 01 0 13 WT004139 ...

Page 14: ... Copyright 2008 03 20 V0 Rev 01 0 14 WT004139 ...

Page 15: ... Copyright 2008 03 20 V0 Rev 01 0 15 WT004139 ...

Page 25: ... Copyright 2008 03 20 V0 Rev 01 0 25 WT004139 DECLARATION OF CONFORMITY ...