19

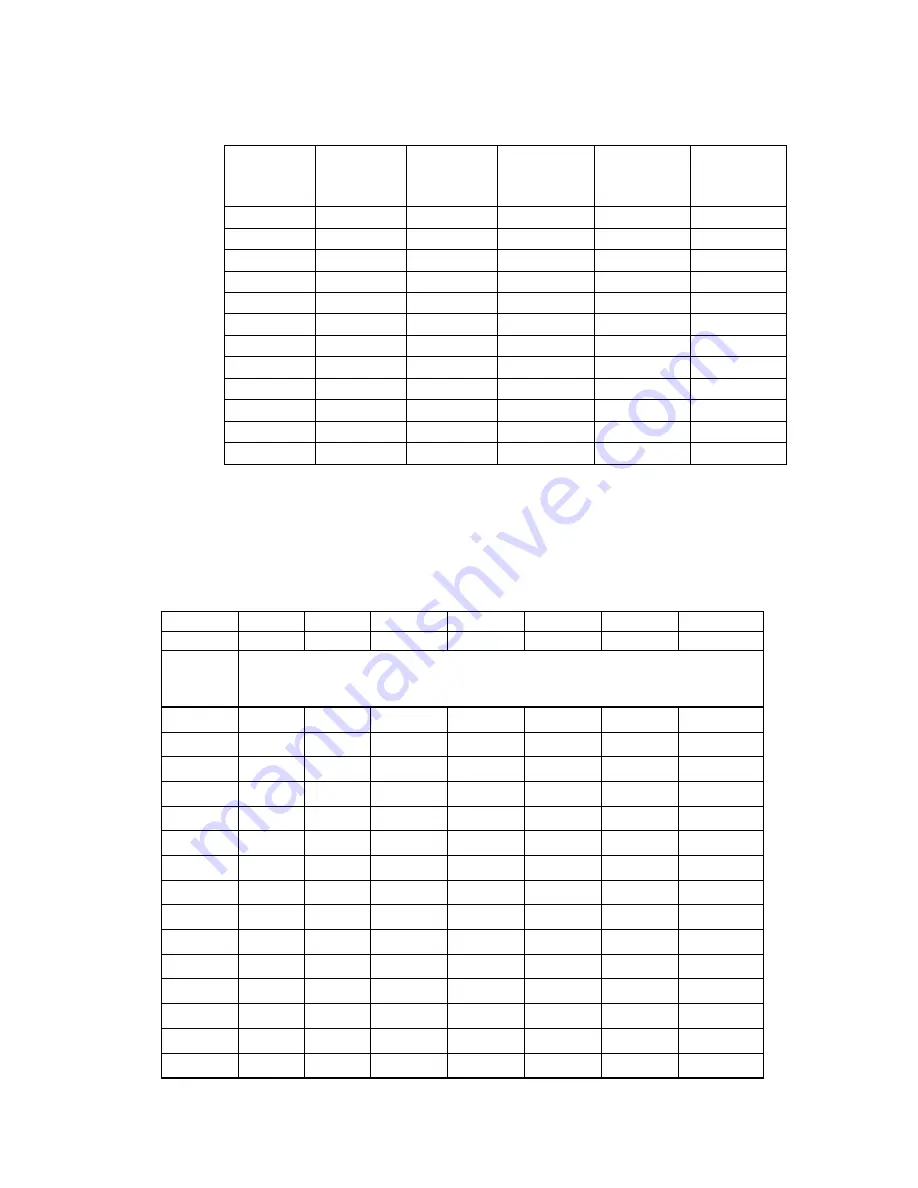

Table 1: Pipe Sizing Chart for Natural Gas (0-0.5 psi) with Straight Schedule 40 Metal Pipe

The following chart is based on

0-0.5 psi

inlet pressure, specific gravity of

0.6

, and a pressure loss of

0.5”

w.c..

Maximum Capacity of Pipe Size in Btu/hr

Length of

Pipe (ft)

1/2”

3/4”

1”

1 1/4”

1 1/2”

10

175,000

360,000

680,000

1,400,000 2,100,000

20

120,000

250,000

465,000

950,000

1,460,000

30

97,000

200,000

375,000

770,000

1,180,000

40

82,000

170,000

320,000

660,000

990,000

50

73,000

151,000

285,000

580,000

900,000

60

66,000

138,000

260,000

530,000

810,000

70

61,000

125,000

240,000

490,000

750,000

80

57,000

118,000

220,000

460,000

690,000

90

53,000

110,000

205,000

430,000

650,000

100

50,000

103,000

195,000

400,000

620,000

150

40,000

84,000

160,000

325,000

500,000

200

35,000

72,000

135,000

280,000

430,000

Table 2: Pipe Sizing Chart for LP

(11” w.c.)

with Straight Schedule 40 Metal Pipe

The following chart is based on

11” w.c.

inlet pressure and a pressure drop of

0.5” w.c..

Special use:

Piping sizing between single or second stage (low pressure regulator) and appliance.

Maximum Capacity of Pipe Size in Btu/hr

Pipe Size

1/2”

3/4”

1”

1 1/4”

1 1/2”

2”

3”

Actual ID

0.622

0.824

1.049

1.38

1.61

2.067

3.068

Length of

Pipe

(feet)

Maximum Capacity in Btu/hr

10

291,000 608,000 1,145,000 2,352,000 3,523,000 6,786,000 19,119,000

20

200,000 418,000

787,000

1,616,000 2,422,000 4,664,000 13,141,000

30

160,000 336,000

632,000

1,298,000 1,945,000 3,745,000 10,552,000

40

137,000 287,000

541,000

1,111,000 1,664,000 3,205,000

9,031,000

50

122,000 255,000

480,000

984,000

1,475,000 2,841,000

8,004,000

60

110,000 231,000

434,000

892,000

1,337,000 2,574,000

7,253,000

80

94,000

197,000

372,000

763,000

1,144,000 2,203,000

6,207,000

100

84,000

175,000

330,000

677,000

1,014,000 1,952,000

5,501,000

125

74,000

155,000

292,000

600,000

899,000

1,730,000

4,876,000

150

67,000

140,000

265,000

543,000

814,000

1,568,000

4,418,000

200

58,000

120,000

227,000

465,000

697,000

1,342,000

3,781,000

250

51,000

107,000

201,000

412,000

618,000

1,189,000

3,351,000

300

46,000

97,000

182,000

373,000

560,000

1,078,000

3,036,000

350

42,000

89,000

167,000

344,000

515,000

991,000

2,793,000

400

40,000

83,000

136,000

320,000

479,000

922,000

2,599,000

Summary of Contents for HSG200

Page 30: ...30 Figure 20 Flame Current Measurement Top Wayne control Bottom Honeywell control...

Page 48: ...48 Figure 29 continued Junction Box Assemblies Exploded Figure 30 Motor Assembly Exploded...

Page 49: ...49 Figure 31 Gun Assembly Exploded Figure 32 HSG Series Burner Exploded...

Page 52: ...52 NOTES...