2

19. To reduce the risk of electrical

shock, the pump should be plugged

directly into a properly installed

and grounded 3-prong grounding

type receptacle, as shown in

Figure 1. The green (or green and

yellow) conductor in the cord is the

grounding wire. The motor must be

securely and adequately grounded

for protection against shock.

20. Where a 2-prong is encountered,

replace the plug with a properly

grounded 3-prong receptacle in

accordance with the National Electrical

Code, local codes and ordinances.

To ensure a proper ground, the

grounding means must be tested by a

licensed or certified electrician.

21. Use only 3-wire extension cords that

have a 3-prong, grounding type plug,

and 3-pole receptacles that accept

the equipment plug.

22. Use wire of adequate size to

minimize voltage drop at the motor.

Do not handle

pump or pump motor

with wet hands, when standing on a wet

or damp surface or when standing in

water. Fatal electrical shock could occur.

Pump motor is

equipped with an

automatic resetting thermal protector

and may restart unexpectedly. Protector

tripping is an indication of motor

overloading because of operating pump

at low heads (low discharge restriction),

excessively high or low voltage,

inadequate wiring, incorrect motor

connections or defective motor or pump.

Pre-Installation

WATER SUPPLIES

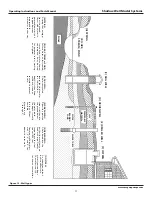

The water supplies illustrated in Figure

13 are possible sources for water. These

water supplies can be divided into two

categories:

SURFACE WATER

Water from a lake, stream, pond and

cistern. This water is usually not fi t

for human consumption, but may be

suitable for washing, irrigation or other

household uses.

GROUND WATER

Water found in the water bearing

stratum at various levels beneath the

General Safety

Information

(Continued)

earth. Of all the fresh water found on

earth only 3 percent is found on the

surface and 97 percent is underground.

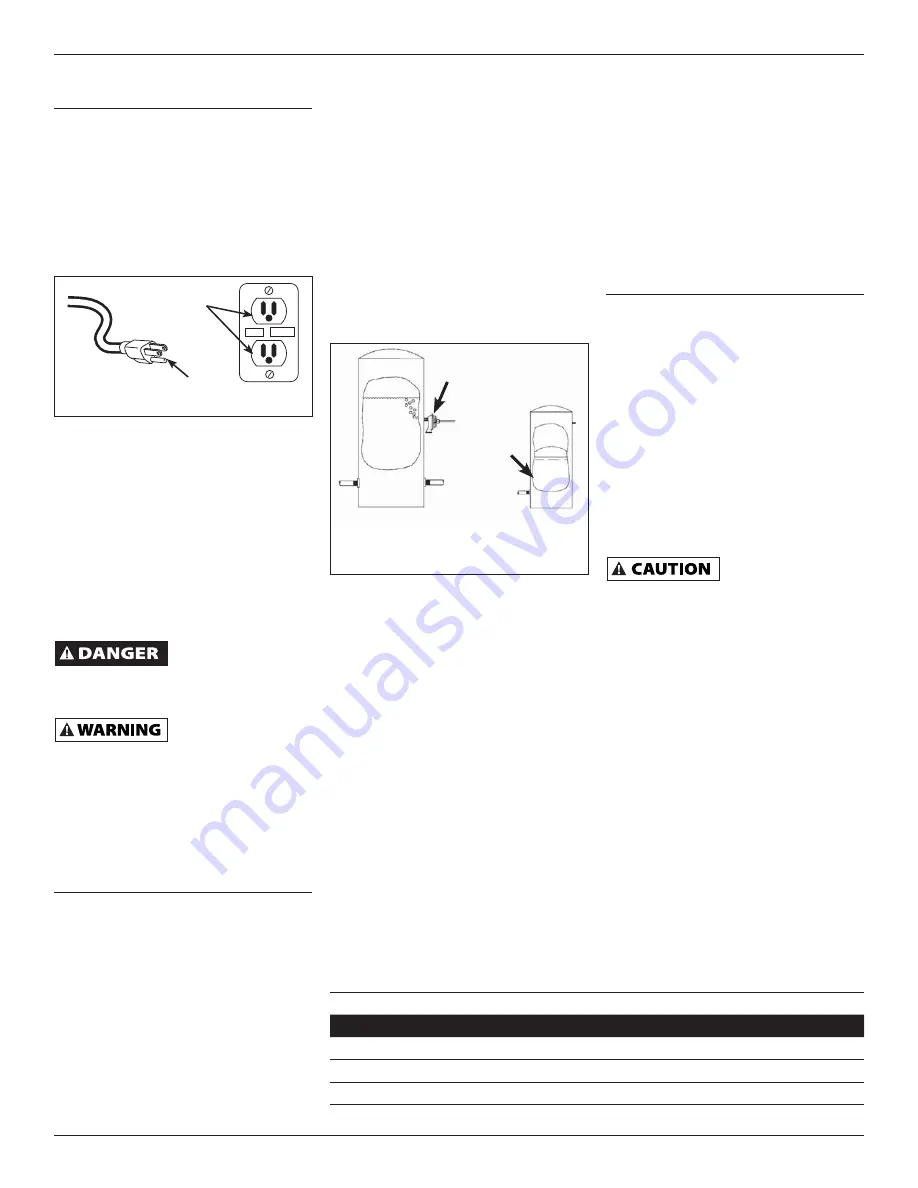

TANKS - CONVENTIONAL STORAGE

The function of the tank is to store a

quantity of water under pressure. When

full, the tank contains approximately

2/3 water and 1/3 compressed air. The

compressed air forces the water out

of the tank when a faucet is opened.

An air volume control automatically

replaces air lost or absorbed into the

water. The usable water, or drawdown

capacity, of the tank is approximately

1/6 of the tanks total volume when

operated on a “20-40” pressure setting

(Figure 2).

TANKS - PRECHARGED STORAGE

A precharged storage tank has a fl exible

bladder or diaphragm that acts as a

barrier between the compressed air

and water. This barrier prevents the

air from being absorbed into the water

and allows the water to be acted on by

compressed air at initially higher than

atmospheric pressures (precharged).

More usable water is provided than with

a conventional type tank. Precharged

tanks are specifi ed in terms of a

conventional tank. For example, a 20

gallon precharged tank will have the same

usable water or drawdown capacity as a

40 gallon conventional tank, but the tank

is smaller in size (Figure 2).

PRESSURE SWITCH

The pressure switch provides for

automatic operation. The pump starts

when pressure drops to a cut-in setting.

The pump stops when pressure reaches a

cut-out setting.

TEST

RESET

Grounded Pin

Grounded

Outlet

Figure 1

PACKAGE SYSTEMS

There are four jet pump/tank assemblies

sold as packages (Chart 1).

WELLS

A new well should be pumped clear of

sand before installing the pump. Sand

will damage the pumping parts and seal.

The draw-down level of the well should

not exceed the maximum rated depth

for the pump. The capacity of the pump

will be reduced and a loss of prime may

occur.

Installation

LOCATION

Select a location as close to the water

supply as possible. Be sure to comply

with any state or local codes regarding

the placement of the pump. The

equipment must be protected from the

elements. A basement or heated pump

house is a good location. Make sure

the pump has proper ventilation. The

temperature surrounding the pump is

not to exceed 100° F (40°C) or nuisance

tripping of the motor overload may

occur.

PIPING

Piping may be copper, steel, rigid PVC

plastic or fl exible polyethylene plastic.

Flexible pipe is not

recommended on

suction pipe (inlet pipe).

The pipe must be clean and free of rust

or scale. Use a pipe joint compound

on the male threads of the metal pipe.

Tefl on® tape should be used with plastic

threads. All connections must be air

tight to insure normal operation.

Slope all inlet piping upwards towards

the pump to prevent trapping air.

Unions or hose couplings can be

installed near pump to facilitate removal

for servicing or storage. A rubber hose

installed between the water system and

the house piping will reduce the noise

transmitted to the house.

PIPE SIZES

Long horizontal pipe runs and an

abundance of fi ttings and couplers

decrease water pressure due to friction

loss. See Chart 2 to determine the proper

pipe size.

www.waynepumps.com

Operating Instructions and Parts Manual

Shallow Well Model Systems

Figure 2 - Conventional & Precharged

Storage Tanks

Precharged

Tank

Conventional

Tank

Bladder

Air Volume Control

CHART 1 - JET PUMP/ TANK ASSEMBLIES

Type

Air Volume Congrol Required

Well X

Precharged

No

PCA

Precharged

No

12P & 30P

Conventional

Yes

FX Horizontal

Precharged

No

Summary of Contents for Shallow well model

Page 6: ...6 Operating Instructions and Parts Manual Shallow Well Model Systems www waynepumps com Notes...

Page 7: ...7 Operating Instructions and Parts Manual Shallow Well Model Systems Notes www waynepumps com...

Page 8: ...8 Operating Instructions and Parts Manual Shallow Well Model Systems www waynepumps com Notes...