SHALLOW WELL PUMP WITH

CONVENTIONAL STORAGE TANK

(FIGURES 4 & 5)

1. Install air volume control on tank.

2. Connect the copper tube from the air

volume control to the uppermost 1/8”

NPT opening on the side of pump. Be

sure the connections are tight. Leaking

can cause the pump not to prime.

3. Install a valve and an isolator hose

between the tank and the house plumbing

to aid in pump removal for servicing and

for reducing the noise transmitted to the

house thrugh the piping.

4. Provide a hose bib (faucet) at the

lowest point in the system to drain

the system for service or storage.

SHALLOW WELL PUMP WITH

PRECHARGED STORAGE TANK

(FIGURE 6)

3

3. Add pipe until the foot valve is 5 feet

below the lowest anticipated water level.

The foot valve

should be at least 18”

from the bottom of the well or sand or

sediment could be drawn into the system.

4. After proper depth is reached, install

a well seal or pitless adapter to

support pipe and prevent surface

water and other contaminants from

entering well.

5. Slope the horizontal pipe upward

toward the pump to eliminate

trapping air. Sloping the pipe will

also aid in priming the pump.

DRIVEN WELL (FIGURE 13)

1. Drive the point several feet below the

water table.

NOTE:

A packer type foot valve can

be installed in the well (Figure 3,

Illustration B). This type of foot valve

allows the well to be fi lled with water

when priming and makes the inlet pipe

much easier to test for leaks. Follow

the manufacturer’s instructions when

installing the packer type foot valve.

As an alternative, an in-line check valve

can be used with a driven well (Figure

3, Illustration C). The pipe between

the check valve and the water level will

always be under a vacuum.

Leaking joints or couplings will allow

air to leak into the pipe and cause

abnormal pump operation. Make sure

to use pipe joint compound on all male

pipe threads.

DUG WELL, CISTERN, LAKE AND

SPRING INSTALLATION (FIGURE 13)

1. Install a foot valve on inlet pipe and

lower into water.

The foot valve should

be at least 18” from

the bottom of the well or sand or

sediment could be drawn into the system.

NOTE:

When a lake is used as a water

supply, make sure the inlet pipe is deep

enough to be submerged at all times.

Slope the horizontal piping upward

toward the pump to prevent trapping air.

The pipe must be removed during winter

months or protected against freezing.

Protect the pipe from damage from

swimmers and boats.

Install a screen

around the inlet pipe

to prevent the entrapment of swimmers.

www.waynepumps.com

Operating Instructions and Parts Manual

Shallow Well Model Systems

Installation

(Continued)

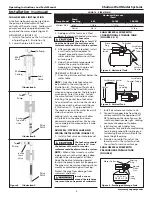

To Pump

Well

Seal

Foot

Valve

Well

Casing

To

Pump

To

Pump

Drive

Point

Drive

Point

Incline

Check

Valve

Packer

Type Foot

Valve

Illustration A

Illustration C

Illustration B

Figure 3

CHART 2 - PIPE SIZING

Pump Model

Pump

Opening

Horizontal Distance

(Feet)

0-25

26-100

100-300

Shallow Well

Inlet

1-1/4 in.

1-1/2 in.

2 in.

Outlet

3/4 in.

1

1-1/4 in.

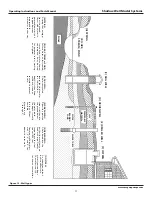

Figure 5 - Vertical Tank

Outlet

Air Volume

Control Tubing

Hose

Coupling

Air Volume Control

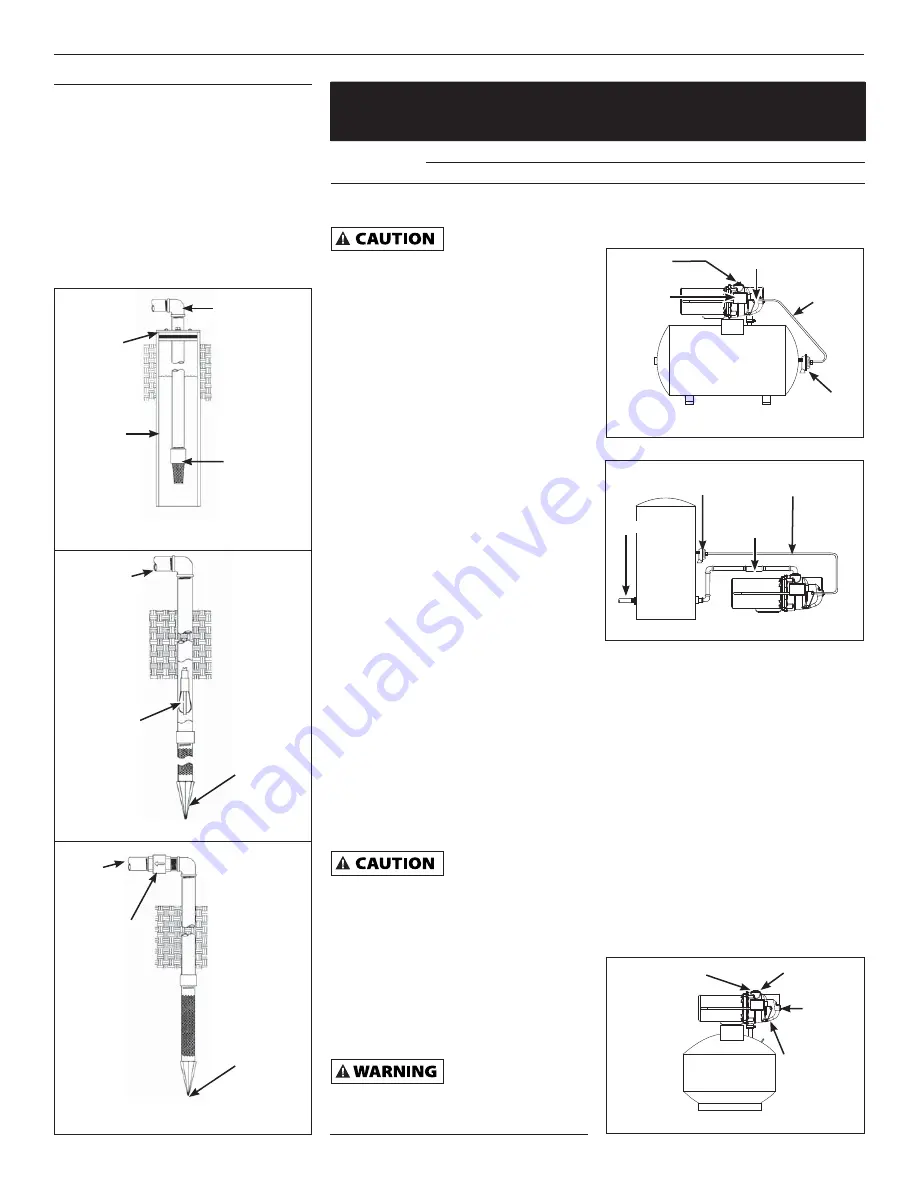

Figure 6 - Precharged Storage Tank

Motor Outlet

Priming

Plug

Nozzle

Clean

Out

Drain

Fitting

28-30 psi

3/4 HP & 1 HP

SHALLOW WELL INSTALLATION

A shallow well pump can be used when

the pump is located within 25 feet

vertically of the water level. Shallow well

pumps have only one pipe between the

pump and the water supply (Figure 3).

DRILLED WELL (FIGURE 13)

1. Install a foot valve on the first section

of pipe (Figure 3, Illustration A).

2. Lower the pipe into the well.

Figure 4 - Horizontal Tank

Air Volume

Control

Tubing

To Suction

Air

Volume

Control

Pressure

Switch

Prime

Plug

Summary of Contents for Shallow well model

Page 6: ...6 Operating Instructions and Parts Manual Shallow Well Model Systems www waynepumps com Notes...

Page 7: ...7 Operating Instructions and Parts Manual Shallow Well Model Systems Notes www waynepumps com...

Page 8: ...8 Operating Instructions and Parts Manual Shallow Well Model Systems www waynepumps com Notes...