4

Operating Instructions and Parts Manual

Shallow Well Model Systems

1. Shut off the power to the pump.

2. Open the faucet nearest the tank and

allow all water to drain from the tank.

3. Measure the tank precharge at the

valve stem using a tire pressure gauge.

4. If necessary, precharge with an air

pump to 28 - 30 psi on 1/2, 3/4 and 1

HP pumps.

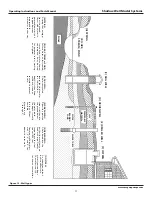

5. Slope the horizontal pipes upward

toward the pump to prevent trapping

air. If the horizontal distance

exceeds 25 feet, see Chart 2 for the

recommended pipe size.

Electrical

Risk of electrical

shock. This pump is

designed for indoor installation only.

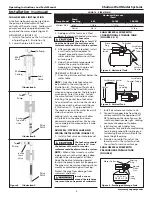

The voltage of power supply must match

the voltage of the pump. All above

ground well pumps except SWS50BOOST

have dual voltage motors preset at the

factory to 115 volts. The motors can be

converted to 230 volts by turning the

voltage selector to the desired voltage

(See Figure 7). Use a needle nose pliers

to pull the selector out approximately

1/4”, rotate and then reinsert in correct

position.

Select the proper size wire and

fuse (Chart 3). Time delay fuses are

recommended over standard fuses for

motor circuit protection. All pump

motors have built-in automatic overload

protection that will prevent damage to

the motor due to overheating.

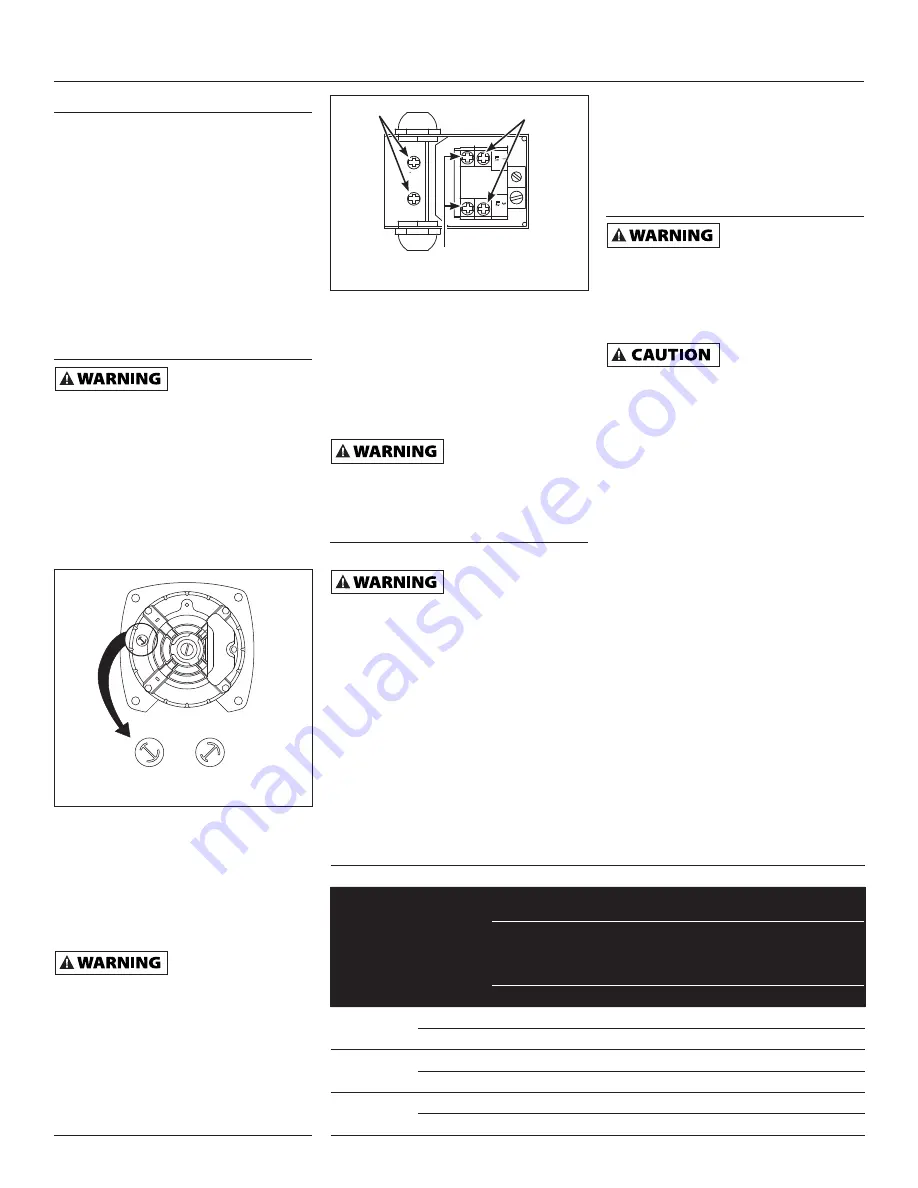

Do not connect to

electric power supply

until unit is permanently grounded.

Connect ground wire to approved

ground then connect terminal provided.

A metal underground water pipe or well

casing at least 10 feet long makes the

best ground electrode. If plastic pipe or

insulated fi ttings are used, run a wire

directly to the metal well casing or use

a ground electrode furnished by the

power company.

There is only one proper ground

terminal on the unit. The terminal(s) is

located under the pressure switch cover,

is painted green and is identifi ed as

GRD. The ground connection must be

made at this terminal (Figure 8). The

ground conductor must not be smaller

than the circuit conductors supplying the

motor.

Disconnect

power

and release all

pressure from the system before

attempting to install, service, relocate or

perform any maintenance.

Operation

PRIMING THE SHALLOW WELL PUMP

To prevent damage

to the pump, do not

start motor until pump has been fi lled

with water.

1. Remove prime plug (Figure 4 or 5).

2. Fill pump and piping completely full

of water.

3. Replace the prime plug.

4. Open a faucet to vent the system.

5. Start the motor. Water will pump in

a few minutes. If pump fails to prime

in 5 minutes, stop motor and refill

pump with water. Priming time is

proportional to the amount of air in

inlet pipe.

6. Let the system operate for several

minutes to flush all pipes.

7. Close faucet and allow pump to build

pressure in tank. When the pressure

reaches the cut-out setting, the

motor will stop.

The system is now in operation and will

automatically cycle on demand.

Maintenance

Disconnect

power

and release all

pressure from the system before

attempting to install, service, relocate

or perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

Protect the pump

from freezing during

winter conditions.

DRAINING THE PUMP

Drain openings are provided on all

models. To drain the pump:

1. Remove drain plug and prime plug to

vent the system.

2. Drain all piping to a point below the

freeze line.

DRAINING THE TANK

Conventional tanks can be drained by

opening an outlet at the lowest point

in the system. Remove plug or the air

volume control to vent the tank.

Precharged tanks force virtually all

the water from the tank when system

pressure is released. No draining is

necessary.

RESTARTING PUMP

If the pump has been serviced, drained

or has not been used for some time,

be sure there is water in the pump

housing (volute) and the piping to the

well. There must be water in the pump

housing (volute) at all times when

the pump is running to avoid internal

damage of seal members (Priming the

Shallow Well).

www.waynepumps.com

115 V

230 V

115 V

230 V

Figure 7 - Voltage Selector

L2

3

L1

1

Figure 8 - Electrical Connections

Line

Motor

Ground

Screw

CHART 3 - RECOMMENDED FUSE & WIRING DATA - 60 HZ MOTORS

HP

VOLT

Distance in Feet

From Meter to Motor

0

51

101

201

to

to

to

to

50

100

200

300

Wire Size

1/2

115

15

14

14

10

230

10

14

14

14

3/4

115

15

14

14

8

230

10

14

14

14

1

115

20

12

12

8

230

10

14

14

14

Installation

(Continued)

Summary of Contents for Shallow well model

Page 6: ...6 Operating Instructions and Parts Manual Shallow Well Model Systems www waynepumps com Notes...

Page 7: ...7 Operating Instructions and Parts Manual Shallow Well Model Systems Notes www waynepumps com...

Page 8: ...8 Operating Instructions and Parts Manual Shallow Well Model Systems www waynepumps com Notes...