4

INSTALLATION (ELECTRICAL)

Operating Instructions and Parts Manual

www.waynepumps.com

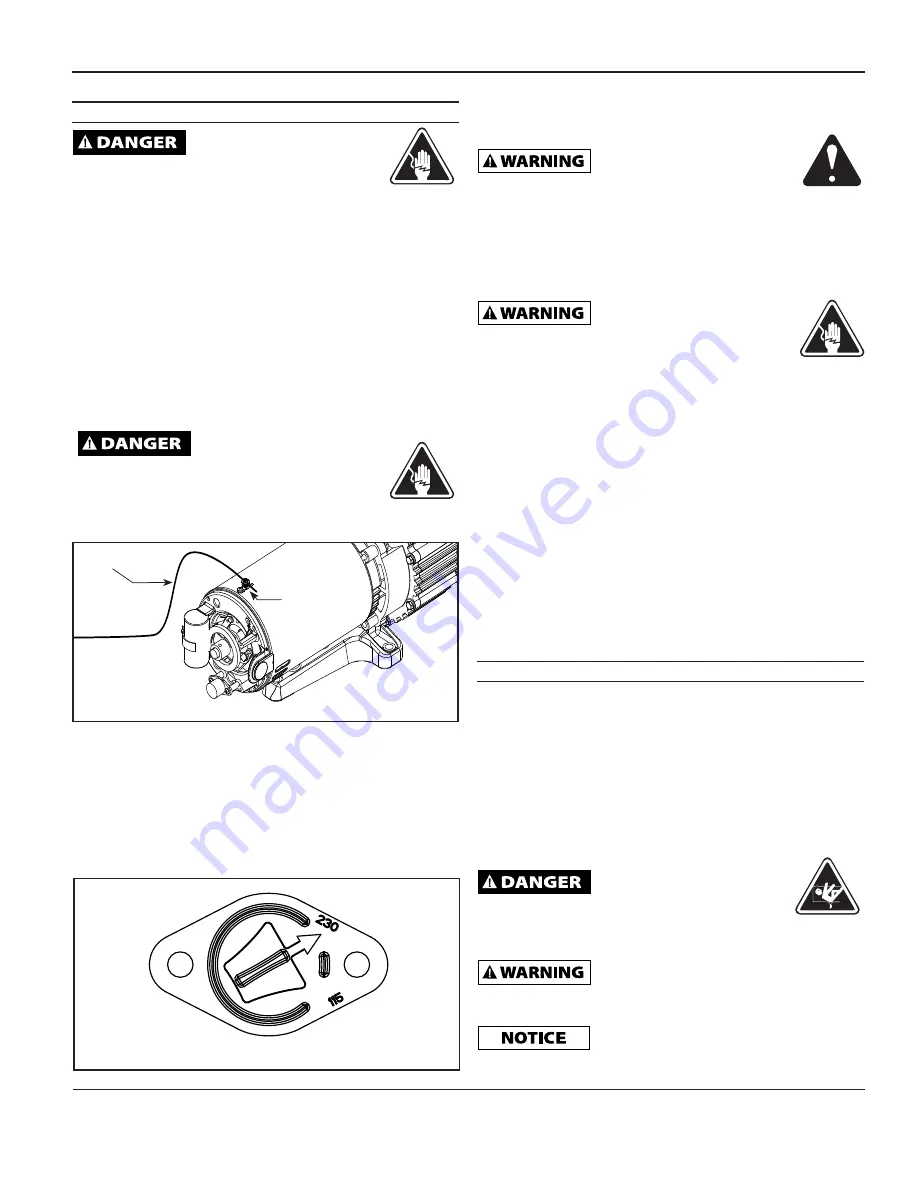

Figure B - Remove back motor cover

This pump is factory wired for 230 volts. To change the voltage to 115 volts

follow the steps below:

1. Disconnect the pump from power.

2. Remove cover from back of motor to find voltage selector (Figure B).

3. Pull selector knob out.

4. Rotate selector knob to correct voltage setting (Figure C).

5. Push selector knob back in place.

6. Reinstall cover to back of motor.

Figure C - Voltage selector setting

Verify supply voltage matches the nameplate voltage. Incorrect voltage

can cause fire or seriously damage motor and voids warranty.

GROUNDING/BONDING

Install, ground, bond and wire motor according to local or National

Electrical Code requirements. Permanently ground the motor. Use ground

terminal provided in the terminal box on the back of the motor. Use size

and type wire required by local codes. Connect motor ground terminal to

electrical service ground.

Bond motor to swimming pool structure. Bonding connects all metal parts

within and around the swimming pool with a continuous wire. Bonding

reduces the risk of current passing between metal objects which could

cause electrical shock. Reference NEC local codes for all wiring standards.

Use a solid copper conductor, size No. 8 AWG or larger. Run wire from

external bonding lug located on top of motor (Figure B) to reinforced rod

or mesh.

BONDING LUG

CONNECTION

BONDING WIRE

OPERATION

Prime pump before attempting to operate. To prime pumps located

above water level, remove strainer cover, fill strainer body with water, then

replace cover. If pump and all piping are located below water level, the

pump will self prime. After pump has been primed, energize motor and

open all suction and discharge line valves. If no flow is observed in five

minutes, stop the motor and re-prime. If the pump fails to operate, check

for air leaks. Refer to troubleshooting section. After about 10 minutes

of operation, check the return fittings for air bubbles. A continuous flow

of air indicates leaks in the suction line. Locate and correct any leaks

immediately.

Disconnect, tag, and lock out

power source before

attempting to install, service, relocate or perform any

maintenance.

NOTE: This pump must be installed by a licensed electrician that

is familiar with swimming pool/spa operations and in accordance

with the NFPA 70 – National Electric Code.

Follow all national and local wiring codes. If unsure of code

requirements consult a professional electrician. Pump must be

permanently connected to a dedicated circuit. If unsure consult

a licensed electrician.

IMPORTANT: Use copper conductors only.

Refer to information on motor nameplates for electrical service

data. Install motors with a fused disconnect switch or a dedicated

circuit breaker. Be sure wire size is sufficient for pump HP and

distance from power source.

Electric shock hazard. Connect

this pump to a properly

grounded GFCI (Ground Fault Circuit Interrupter)

receptacle that is rated for at least 15 amps. Test the

operation of the GFCI receptacle according to the

manufacturer’s recommended intervals.

GFCI is required in the circuit. For size of GFCI required and test

procedures for GFCI, see manufacturer’s instructions.

GFCI tripping indicates an electrical problem. If GFCI trips, determine

the reason for tripping. If you are uncertain, have a licensed or certified

electrician that is familiar with swimming pool/spa operations and

in accordance with the NFPA 70 – National Electric Code inspect

and repair the electrical system.

This pump MUST be installed by

a licensed or certified electrician

that is familiar with swimming pool/spa operations

and in accordance with the NFPA 70 - National Electric

Code.

Suction hazard. Do NOT block

the pump suction with your

body. Failure to do so WILL result in death or serious

bodily injury.

NOTE: Small children using pool must ALWAYS have close adult supervision.

Fire and burn hazard. Motor runs at high

temperatures, to reduce the risk of fire, do

NOT allow debris or foreign matter to collect around the pump motor.

Allow motor to cool prior to handling or performing maintenance.

Do NOT operate pump without strainer.

Foreign material may interfere with

impeller causing pump to stop.

NEVER ground to a gas supply

line, use dedicated grounding

system

.