For Replacement Parts or

Technical Assistance, call

1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

WAYNE Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

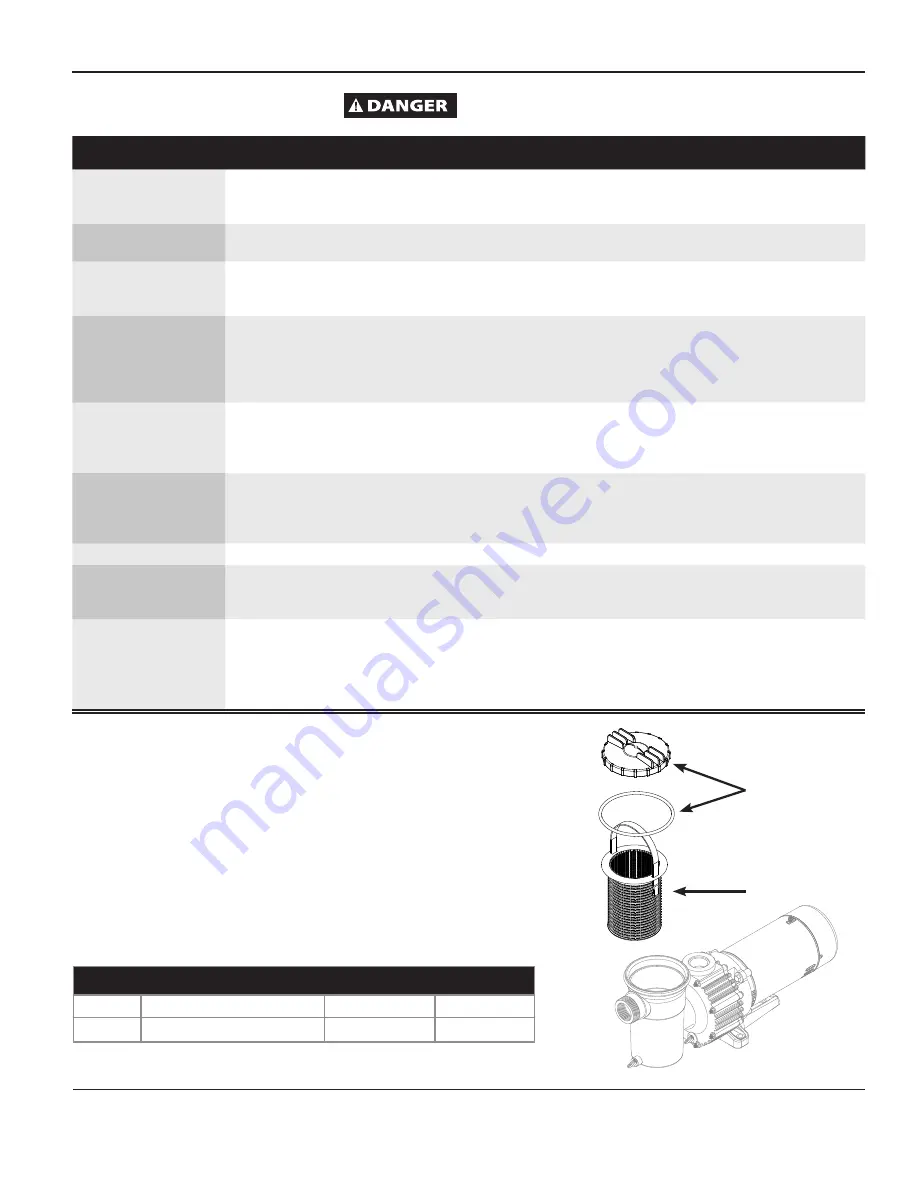

Ref. No.

Description

Order No.

Quantity

1

Strainer Cover and Gasket

69010-001

1

2

Strainer

28477-001

1

1

2

6

www.waynepumps.com

Troubleshooting and Replacement Parts

Troubleshooting Chart

Symptoms

Possible Cause(s)

Corrective Action

Motor does not start

1. Disconnect switch or circuit breaker in OFF position

2. Fuses blown or thermal overload open

3. Disconnected or defective wiring

1. Reset breaker

2. Check voltage

3. Check wiring

Motor does not reach full

speed

1. Low voltage

2. Motor windings connected for wrong voltage

1. Check voltage settings

2. Inspect motor voltage selector

Motor overheats

(protector trips)

1. Low voltage

2. Motor windings connected for wrong voltage

3. Inadequate ventilation

1. Check voltage settings

2. Inspect motor voltage selector

3. Remove obstructions around pump

Pump does not deliver

water

1. Pump is not primed

2. Suction or discharge valve is closed

3. Leakage or air into suction system

4. Hair and lint strainer is full

5. Water level in swimming pool is too low

1. Prime pump as directed in the “Operation” section

2. Open the valve

3. Eliminate leaks in suction line

4. Clean strainer (see maintenance section)

5. Fill swimming pool to proper level

Noisy pump and motor

1. Plugged basket in skimmer or hair in lint strainer

2. Valve in suction line partly closed

3. Vacuum hose plugged or too small

4. Pump not supported properly

1. Clean skimmer and lint strainer

2. Open all valves during operation

3. Check for collapsed hose and replace

4. Add additional supports

Low pump capacity

1. Valve in suction or discharge line partly closed

2. Suction or discharge line too small

3. Plugged basket in skimmer or hair in lint strainer

4. Dirty filter

1. Open all valves

2. Use larger supply line

3. Clean skimmer and lint strainer

4. Clean filter (see filter manual)

Leakage of water at shaft

1. Shaft seal requires replacement

1. Replace seal

High pump pressure

1. Discharge valve closed

2. Return lines too small

3. Dirty filter

1. Always run with valves open

2. Replace with larger lines

3. Clean filter (see filter manual)

Air bubbles collecting in

strainer

1. Leakage of air into suction line at connections or valve

stem

2. Strainer cover leaking

3. Restriction in suction line

4. Low water level in swimming pool

1. Eliminate leaks in suction line

2. Remove and clean o-ring

3. Increase suction line size

4. Fill swimming pool to correct level

Electrocution hazard! Pump can start automatically. Disconnect

the power before attempting any repairs. Failure to follow these

instructions WILL result in serious injury or death.