INSTALLATION

INSTALLATION OF THIS UNIT MAY TAKE

SEVERAL HOURS. BEFORE DISABLING YOUR MAIN PUMP, HAVE READY AN

APPROPRIATE MEANS OF EVACUATING THE SUMP.

1. Turn power to main pump off.

2. Pump must be installed using 1-1/4 in. or 1-1/2 in. rigid

PVC piping. Do not use flexible hose.

THIS INSTALLATION MUST BE IN ACCORDANCE WITH

THE NATIONAL ELECTRIC CODE AND ALL APPLICABLE LOCAL CODES AND

ORDINANCES.

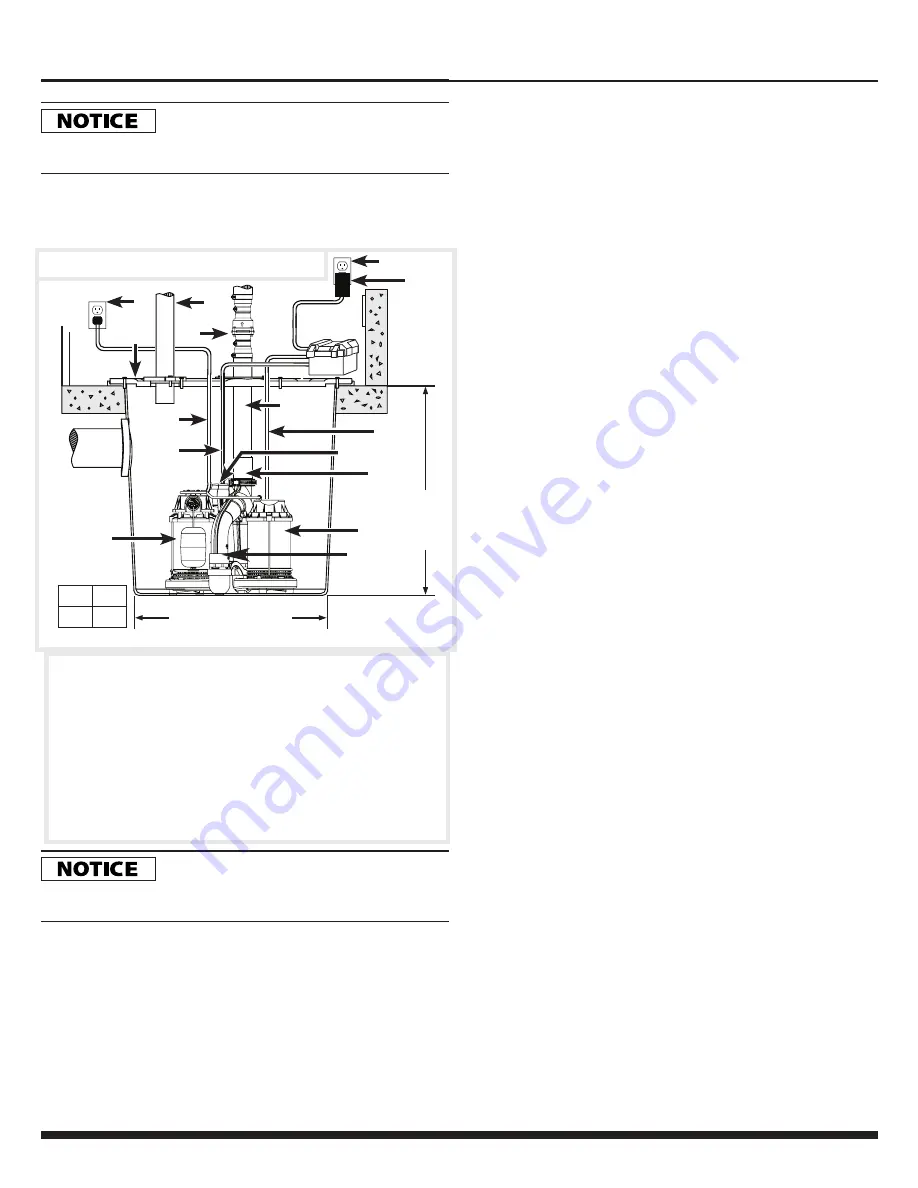

3. Use a basin (purchased seperately) or pit that is large enough

to accommodate the system. The minimum requirements for

the sump system are shown in Figure 1.

4. Clean the basin/pit of all debris.

5. If using a basin, place the system directly on the bottom of

the basin.To prevent damage set the system on a solid, level

surface. Do not place units directly on clay, earth, gravel or

sand. A brick or blocks can be installed under the pumps to

provide a solid base.

6. Position system so the float switch is away from the inlet

so float switch is clear from incoming water. Verify the float

has at least 1 in. clearance to the side wall of the basin and

is free to move throughout its travel.

7. Install discharge plumbing according to local, regional

and state codes. Rigid PVC pipe is required. Do not

use flexible hose in a permanent application. A 1-1/2

PVC schedule 40 coupling is required on diverter valve

discharge. Do not use schedule 20 couplings or drainage

fittings.

8. Install removable check valve (8) (Wayne Part Number:

57028-001) positioned just above the basin to allow easy

removal of the system for cleaning

and service. Note: A check valve is required to prevent

back-flow.

9. Install a gate valve or ball valve if required by local, regional

or state code.

10. Connect pump power supply cord to a ground fault circuit

interrupter (GFCI) outlet (1).

1. GFCI GROUNDED OUTLETS

2. AC PUMP POWER CORD

3. DC PUMP POWER CORD

4. DISCHARGE PIPE

5. AC PUMP (Primary)

6. DC PUMP (Secondary)

7. VENT PIPE

8. REMOVABLE CHECK VALVE

9. GASKET/BASIN LID

10. BATTERY BOX CONTROLLER

11. DC FLOAT SWITCH

12. DC FLOAT SWITCH CORD

13. TRANSFORMER

14. 11/2” PVC SCHEDULE 40

COUPLING

15. DIVERTER VALVE

Figure 1: Submersible Sump System

1

15

3

5

8

9

6

15 IN. DIAMETER MIN.

14

4

10

12

13

11

MINIMUM

BASIN

DEPTH

(22 IN.)

ON

LEVEL

AC

9"

10"

NA

4"

DC

OFF

LEVEL

2

7

1

Operating Instructions and Parts Manual

5

www.waynepumps.com

WSS30Vn